21

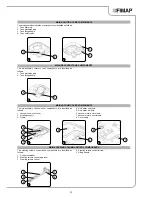

REGULATING THE DETERGENT

To regulate the detergent, proceed as follows:

1. Verify that the quantity of detergent solution in the solution tank

is suitable for the type of work you wish to carry out, otherwise fill

the solution tank (see the paragraph “

FILLING THE SOLUTION

TANK

”).

2.

Check that the brush head is resting on the floor.

3. Activate the appliance using the main switch (1) (

Fig.1

).

4. By pressing on the dead man's lever the appliance starts to work.

5.

During the first few metres, press the pump command button (2)

to regulate the flow of detergent onto the brush (

Fig.2

).

By pressing the button (2) on the control display(

Fig.2

), a horizontal

line will appear. This line is made up of three positions (

Fig.3

) and, as

you continue to press the button, small rectangles will appear. There

are three possible adjustments which can be made to the detergent

solution flow.

If the display only shows the horizontal line, no detergent solution is

being released (

Fig.4

). This mode is used when the floor is already

wet or in general when the chemical action of water and detergent

solution is not necessary.

For each press of the button (2), the quantity of solution released will

increase by one level. The quantity of solution released can be set to

three successive levels. Once the maximum level has been reached

(

Fig.3

), a further press on the button will return you to level 0 (no

detergent solution).

ATTENTION:

Passing from one step to another is a

continuous cycle - it is not possible to go back except by

continuing to the end of the scale and starting again from

zero.

ATTENTION:

By holding down the button (2), the pump flow

is brought back to zero

(

Fig.4

)

.

ATTENTION:

If the machine is switched off via the main

switch, the flow of detergent will return to step-01.

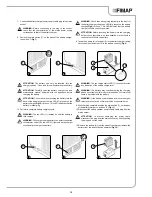

OVERFLOW DEVICE

The appliance is

NOT

equipped with an overflow device, because

the volume of the recovery tank is greater than the capacity of the

solution tank. In extraordinary cases, there is a mechanical device

(float) beneath the vacuum lid that, when the recovery tank is full,

shuts off the air to the vacuum motor intake to protect it; the sound of

the vacuum motor will then be deeper.

If this is the case, proceed as follows:

1. Release the dead man's lever (1) (

Fig.1

) to disable the brush

motor and the pump. The vacuum motor will also stop working

after a determined lapse of time.

2. As soon as the vacuum motor switches off, de-activate the

device, using the main switch (2) (

Fig.2

).

3.

Lift the squeegee from the floor.

4. Lock the control handlebar, push the steering column control stop

lever (3) in the direction indicated by the arrow (

Fig.3

).

The appliance must not be

transported or parked in its idle

position when the solution tank

and recovery tank are full.

1

2

1

2

ON

3

4

2

3

1

2

3

1

OFF