14

WARM AIR FURNACE

TABLE 3: HIGH ALTITUDE SPECIFICATIONS - CANADA

MODEL

Input x

1000

ALTITUDE

Feet

INPUT

BTU/hr

OUTPUT

BTU/hr

NAT.

ORIFICE

L.P.

ORIFICE

QTY.

QTY.

2

3

4

5

6

7

8

0 - 2000

35,000

28,000

1.95 mm

1.20 mm

35

2000 - 4500

31,500

25,200

1.90 mm

1.15 mm

0 - 2000

50,000

40,000

1.95 mm

1.20 mm

50

2000 - 4500

45,000

36,000

1.90 mm

1.15 mm

0 - 2000

68,000

54,400

1.95 mm

1.20 mm

70

2000 - 4500

61,200

48,960

1.90 mm

1.15 mm

0 - 2000

85,000

68,000

1.95 mm

1.20 mm

85

2000 - 4500

76,500

61,200

1.90 mm

1.15 mm

0 - 2000

100,000

80,000

1.95 mm

1.20 mm

100

2000 - 4500

90,000

72,000

1.90 mm

1.15 mm

0 - 2000

115,000

92,000

1.95 mm

1.20 mm

115

2000 - 4500

103,500

82,800

1.90 mm

1.15 mm

TABLE 4: HIGH ALTITUDE SPECIFICATIONS - UNITED STATES

MODEL

Input x

1000

ALTITUDE

Feet

INPUT

BTU/hr

NAT.

ORIFICE

L.P.

ORIFICE

0 2000

35,000

28,000

1.95 mm

1.20 mm

2

OUTPUT

BTU/hr

0 - 2000

135,000

108,000

1.95 mm

1.20 mm

135

2000 - 4500

121,500

97,200

1.90 mm

1.15 mm

QTY.

2

2

3

4

5

6

7

8

6

7

8

0 - 2000

100,000

80,000

1.95 mm

1.20 mm

100

2000 - 4500

90,000

72,000

1.90 mm

1.15 mm

0 - 2000

115,000

92,000

1.95 mm

1.20 mm

115

2000 - 4500

103,500

82,800

1.90 mm

1.15 mm

TABLE 4: HIGH ALTITUDE SPECIFICATIONS - UNITED STATES

MODEL

Input x

1000

ALTITUDE

Feet

INPUT

BTU/hr

NAT.

ORIFICE

L.P.

ORIFICE

0 - 2000

35,000

28,000

1.95 mm

1.20 mm

2000 - 3000

30,800

24,640

1.83 mm

1.13 mm

3000 - 4000

29,400

23,520

1.79 mm

1.10 mm

4000 - 5000

28,000

22,400

1.74 mm

1.07 mm

35

5000 - 6000

26,600

21280

1.70 mm

1.05 mm

0 - 2000

50,000

40,000

1.95 mm

1.20 mm

2000 - 3000

44,000

35,200

1.83 mm

1.13 mm

3000 - 4000

42,000

33,600

1.79 mm

1.10 mm

4000 - 5000

40,000

32,000

1.74 mm

1.07 mm

50

5000 - 6000

38,000

30,400

1.70 mm

1.05 mm

0 - 2000

68,000

54,400

1.95 mm

1.20 mm

2000 - 3000

59,840

47,872

1.83 mm

1.13 mm

3000 - 4000

57,120

45,696

1.79 mm

1.10 mm

4000 - 5000

54,400

43,520

1.74 mm

1.07 mm

70

5000 - 6000

51,680

41,344

1.70 mm

1.05 mm

0 - 2000

85,000

68,000

1.95 mm

1.20 mm

2000 - 3000

74,800

59,840

1.83 mm

1.13 mm

3000 - 4000

71,400

57,120

1.79 mm

1.10 mm

4000 - 5000

68,000

54,400

1.74 mm

1.07 mm

85

5000 - 6000

64,600

51,680

1.70 mm

1.05 mm

0 - 2000

100,000

80,000

1.95 mm

1.20 mm

2000 - 3000

88,000

70,400

1.83 mm

1.13 mm

3000 - 4000

84,000

67,200

1.79 mm

1.10 mm

4000 - 5000

80,000

64,000

1.74 mm

1.07 mm

100

5000 - 6000

76,000

60,800

1.70 mm

1.05 mm

0 - 2000

115,000

92,000

1.95 mm

1.20 mm

2000 - 3000

101,200

80,960

1.83 mm

1.13 mm

3000 - 4000

96,600

77,280

1.79 mm

1.10 mm

4000 - 5000

92,000

73,600

1.74 mm

1.07 mm

115

5000 - 6000

87,400

69,920

1.70 mm

1.05 mm

OUTPUT

BTU/hr

0 - 2000

135,000

108,000

1.95 mm

1.20 mm

135

2000 - 4500

121,500

97,200

1.90 mm

1.15 mm

0 - 2000

135,000

108,000

1.95 mm

1.20 mm

2000 - 3000

118,800

95,040

1.83 mm

1.13 mm

3000 - 4000

113,400

90,720

1.79 mm

1.10 mm

4000 - 5000

108,000

86,400

1.74 mm

1.07 mm

135

5000 - 6000

102,600

82,080

1.70 mm

1.05 mm

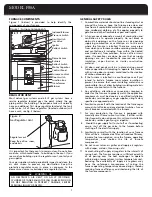

EX

AIRFLOW - CFM

TERN AL STATIC PRESURE - Inches

w.c.

MODEL

FAN

HP

SPEED

0.10

0.20

0.30

0.40

0.50

0.60

HIGH 8

92

900

910

907

899

884

ME D- HI

7 21

730

751

763

769

757

MED-LO 5

89

603

614

625

632

632

35-2

10-4

DD

1/4

LO W

519

527

539

547

556

551

HIGH 1

512

1496

1448

1406

1337

1272

ME D- HI

1 322

1311

1288

1249

1208

1140

MED-LO 9

80

971

963

954

929

896

50-3

10-7

DD

1/3

LO W

754

746

738

735

723

690

HIGH 1

688

1643

1589

1527

1465

1389

MED- HI

1 415

1401

1386

1356

1306

1250

MED-LO 9

88

992

1008

1008

1001

970

70-3

10-8

DD

1/3

LO W

721

736

763

768

765

765

HIGH 1

710

1681

1655

1612

1559

1485

ME D- HI

1 384

1398

1405

1401

1387

1364

MED-LO 9

26

948

975

990

980

964

70-4

10-9

DD

1/2

LO W

714

728

757

763

760

687

HIGH 1

624

1608

1582

1533

1483

1409

MED HI

1 407

1399

1388

1355

1313

1254

MED LO

990

995

999

1005

992

968

85-3

10-8

DD

1/3

LO W

742

752

766

774

774

769

HIGH 2

106

2083

2028

1943

1862

1753

ME D- HI

1 856

1840

1816

1777

1705

1620

MED-LO 1

577

1587

1600

1580

1530

1465

85-4

2 Side

Returns

2 Side

Returns

10-10

DD

1/2

LO W

1325

1342

1368

1386

1371

1314

HIGH 1

766

1747

1738

1711

1653

1602

ME D- HI

1 440

1444

1448

1459

1434

1397

MED-LO 9

88

1008

1027

1042

1060

1005

100-4

10-10

DD

1/2

LO W

768

780

794

747

704

664

HIGH 2

195

2168

2102

2028

1950

1846

ME D- HI

1 915

1900

1892

1854

1785

1713

MED-LO 1

610

1621

1621

1594

1612

1550

100-5

1 Side

Return

12-10

DD

3/4

LO W

1357

1372

1401

1419

1394

1360

HIGH 2

399

2359

2290

2219

2146

2070

ME D- HI

2 175

2116

2070

2007

1959

1892

MED-LO 1

991

1959

1909

1875

1841

1788

100-5

2 Side

Returns

12-10

DD

3/4

LO W

1671

1636

1624

1587

1537

1498

HIGH 2

413

2334

2280

2197

2126

2051

ME D- HI

2 253

2197

2111

2051

1990

1911

MED-LO 2

140

2096

2021

1959

1895

1845

115-5

2 Side

Returns

12-10

DD

3/4

LO W

1820

1789

1735

1679

1644

1597

HIGH 2

100

2082

2054

2012

1954

1910

ME D- HI

1 782

1763

1738

1746

1704

1670

MED-LO 1

433

1437

1444

1440

1422

1411

115-5

Bottom

& Side

Return

12-10

DD

3/4

LO W

1231

1234

1238

1238

1237

1233

HIGH

2550

2468

2403

2323

2239

2167

MED-HI

2309

2239

2182

2108

2047

1984

MED-LO

2182

2123

2077

2015

1968

1902

135-5

2 Side

Returns

Returns

12-10

DD

3/4

LOW

LOW

1833

1800

1779

1723

1653

1618

HIGH

2135

2128

2094

2060

2019

1955

MED-HI

1822

1807

1800

1791

1768

1736

MED-LO

1473

1482

1496

1509

1492

1468

135-5

Bottom

& Side

12 x

10

DD

3/4

1241

1258

1270

1278

1270

1265

TABLE 6: AIRFLOW SPECIFICATIONS

TABLE 4: HIGH ALTITUDE SPECIFICATIONS - USA

TABLE 5: HIGH ALTITUDE SPECIFICATIONS - CANADA

Содержание F80A

Страница 24: ...23 MODEL F80A 50V51 250...

Страница 26: ...25 MODEL F80A R R 3 FACTORY SETTING...