Maintenance - 200 / 400 / 600 / 800 h

If the forward/reverse lever still is stiff after the above

adjustments, lubricate the other end of the control

cable with a few drops of oil. The cable is located on

the top of the propulsion pump.

76

4812274432.pdf

2017-07-10

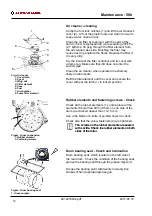

Forward/Reverse controls and joints - Check

and lubrication

Figure. Forward/reverse lever

1. Friction nut

1

Unscrew the protective plate. Check the friction on the

forward/reverse lever. The friction nut (1) should be

applied with sufficient pressure to keep the

forward/reverse lever in the set position during

operation.

If the lever gets stiff after prolonged use, lubricate the

lever at the bearing bushings and at the cable with a

few drops of oil at each place.

3

2

Fig. Engine compartment

1. F/R lever cable

2. Heat cover

3. Air filter

1

Содержание Dynapac CC900G

Страница 2: ......

Страница 16: ...Safety when operating 8 4812274432 pdf 2017 07 10 ...

Страница 20: ...Special instructions 12 4812274432 pdf 2017 07 10 ...

Страница 22: ...Technical specifications Noise Vibrations Electrical 14 4812274432 pdf 2017 07 10 ...

Страница 30: ...Machine description Decals 22 4812274432 pdf 2017 07 10 ...

Страница 42: ...Operation 34 4812274432 pdf 2017 07 10 ...

Страница 54: ...Operating instructions Summary 46 4812274432 pdf 2017 07 10 ...

Страница 56: ...Operating instructions Summary 48 4812274432 pdf 2017 07 10 ...

Страница 58: ...Preventive maintenance 50 4812274432 pdf 2017 07 10 ...

Страница 62: ...Maintenance Lubricants and symbols 54 4812274432 pdf 2017 07 10 ...

Страница 70: ...Maintenance Maintenance measures before use 62 4812274432 pdf 2017 07 10 ...

Страница 80: ...Maintenance 100h 72 4812274432 pdf 2017 07 10 ...

Страница 88: ...Maintenance 500h 80 4812274432 pdf 2017 07 10 ...

Страница 96: ...Maintenance 1000h 88 4812274432 pdf 2017 07 10 ...