RDT-07-0122

53

®

NORD

fire

|

FDMQ

Images are for illustrative purposes

We reserve the right to make changes

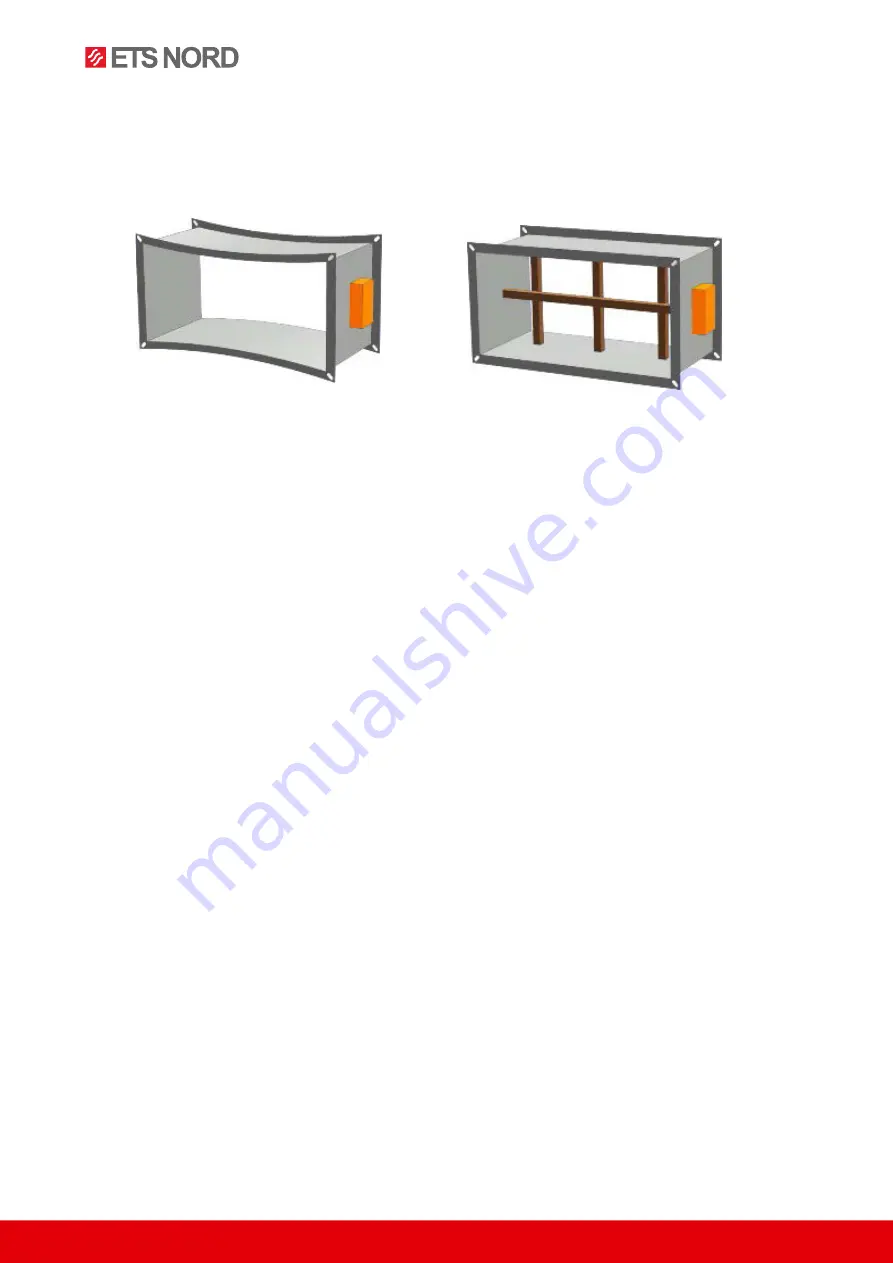

Fig. 50 Embedding/ fixing the damper

Protecting the damper against buckling,

above all when there are big sizes of the fire dampers!

WRONG! Brace with wooden blocks

16.3 All flange and screw joints must be conductively connected during the assembly to provide

protection against dangerous contact. 2 fan-shaped washers in galvanized version are to be

used for conductive connection; they are to be situated under the head of one bolt and under the

screwed nut.

16.4 If the damper is equipped with limit switches and the said devices are not used during operation

(e.g. because of a project change), they can be left on the damper and not connected (they need

not be dismounted). On the other hand, if a limit switch is to be added to the damper design, the

change can be implemented by adding the required device to the base plate of the damper. The

said facts must be recorded in the respective operation documentation of the damper (record

books of the damper, fire logs, etc.) and subsequently, adequate function checks must be carried

out.

16.5 For a reliable function of the dampers, their closing mechanism and the seating faces of the blade

must be protected from dust, fibrous or adhesive masses and solvents.

16.6 Control of actuating mechanism without electric voltage:

You can set the damper blade in any position with the help of a special wrench (included in the

delivery of the actuating mechanism). By turning the wrench in the direction of the arrow, the

damper blade will move to the open position. By stopping the damper blade in any position, the

actuating mechanism will be locked according to the instructions on the actuating mechanism.

The mechanism can be unlocked manually according to the instructions on the mechanism or by

means of supply voltage.

WARNING!

If the actuating mechanism is manually locked, the damper blade will not close in case of

fire after activation of the thermoelectric starting mechanism BAT. To restore the correct

function of the damper, the actuating mechanism must be unlocked (manually or by

means of supply voltage).