SECTION 4 MAINTENANCE

15

4.1 GENERAL

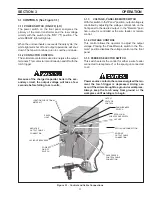

Be sure the branch circuit or main disconnect switch

is off or electrical input circuit fuses are removed

before attempting any inspection or work on the

inside of the welding machine. Placing the power

switch on the welding machine in the OFF position

does not remove all power from inside of the equip-

ment.

Inspection, troubleshooting and repair of this equip-

ment may ordinarily be undertaken by a competent

individual having at least general experience in the

maintenance and repair of semi-conductor elec-

tronic equipment. Maintenance or repair should not

be undertaken by anyone not having such qualifications.

Shut OFF shielding gas supply at source.

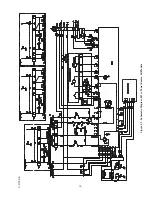

To aid in checking and servicing, use Schematic, Figure

5.1.

4.2 INSPECTION AND SERVICE

Keep Equipment in clean and safe operating condition

free of oil, grease, and (in electrical parts) liquid and

metallic particles which can cause short-circuits.

Regularly check cylinder valves, regulators, hoses, and

gas connections for leaks with soap solution.

Check for and tighten loose hardware including electrical

connection. Loose power connections overheat during

welding.

Immediately replace all worn or damaged power cables

and connectors. Check for frayed and cracked insula-

tion, particularly in areas where conductors enter Equip-

ment.

The electrode wire and all metal parts in contact with it

are electrically energized while welding. Inspect these

parts periodically for defective insulation and other elec-

trical hazards.

If uninsulated cable and parts are not replaced, an

arc caused by a bared cable or part touching a

grounded surface may damage unprotected eyes or

start a fire. Body contact with a bared cable, connec-

tor, or uncovered conductor can shock, possible

fatally.

Keep power cables dry, free of oil and grease, and

protected at all times from damage by hot metal and

sparks.

Clean dirt and metal particles from drive roll groove

weekly; replace roll if badly worn.

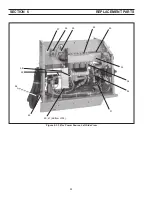

4.3 POWER SOURCE

It is recommended that the rectifier be cleaned occasion-

ally by blowing it out with compressed air. This cleaning

operation is necessary so that maximum cooling will be

accomplished by the air stream. This should be done

periodically, depending upon the location of the unit and

the amount of dust and dirt in the atmosphere.

The hermetically sealed silicon rectifiers are specially

designed for welding machine use and will not age or

deteriorate in use. The diodes are mounted on a heat

sink. A periodic cleaning of dust and dirt from these is

necessary to insure cooling of the rectifiers. Access is by

removal of top cover and side panels. Should any rectifier

accidentally be damaged and need replacement, it can

be quickly removed from the heat sink. The replacement

should be of the same type as the one removed, and

should be locked securely to the sink, preferably with a

torque wrench set for maximum of 25 ft. lbs. and a

minimum of 20 ft. lbs. Excessive torque will distort the

mechanical structure and may break the hermetic seal,

whereas too little torque will result in improper electrical

connections.

4.3.1 FAN MOTOR

All models are equipped with an exhaust fan and rely on

forced draft for adequate cooling for high duty cycles and

overloads.

4.3.2 TRANSFORMER

Occasional blowing out of the dust and dirt from around

the transformer is recommended. This should be done

periodically depending upon the location of the unit and

the amount of dust and dirt in the atmosphere. The

welding machine case cover should be removed and a

clean, dry air stream should be used for this cleaning

operation.

If it should become necessary to replace this or any

other circuit breaker in the welding machine, ensure

that the proper size is used as a replacement.

4.3.3 OVER-TEMPERATURE PROTECTION

The machine is equipped with 2 over-temperature ther-

mostats. On continued high current application, if a

thermostat reaches an abnormally high temperature, it

will deenergize the contactor, the READY light on the

front panel will go off and the fan will continue to run. This

thermostat will reset itself automatically after the trans-

former windings have cooled to a safe level and the

READY light will come back on. While deenergized,

neither the contactor nor wire feeder can be operated.