9

SECTION 2 INSTALLATION

The lifting eyebolt is to be used for lifting power

source only. Do not use when additional accesso-

ries are attached to the power source.

If lifting eyebolt is not installed, the hole must be

plugged to prevent entry of dirt and water.

2.2 ELECTRICAL INPUT CONNECTIONS

It is recommended that a line disconnect switch be

installed in the input circuit to the welding machine.

This would provide a safe and convenient means to

completely remove all electrical power from the

welding machine whenever it is necessary to perform

any internal function on the unit.

Before making electrical input connections to the

welding machine, “Machinery Lockout Procedures”

should be employed. If the connections are to be

made from a line disconnect switch, the switch

should be padlocked in the off position. If the con-

nection is made from a fusebox, remove the fuses

from the box and padlock the cover in the closed

position. If locking facilities are not available, attach

a red tag to the line disconnect switch (or fuse box)

to warn others that the circuit is being worked on.

2.2.1 INPUT ELECTRICAL REQUIREMENTS

The power source is a single-phase unit and must be

connected to a single-phase power supply. The unit

should be operated on a dedicated circuit to prevent

impairment of performance due to an overloaded circuit.

The primary input voltage requirements are noted on the

unit’s rating plate.

2.1 LOCATION

A proper installation site should be selected for the

welding machine, if the unit is to provide dependable

service and remain relatively maintenance free.

A proper installation site permits freedom of air move-

ment into and out of the welding machine, and also least

subjects the unit to dust, dirt, moisture, and corrosive

vapors. A minimum of 18 inches (46 cm) unrestricted

space must be maintained between the welding machine

side and rear panels and the nearest obstruction.

The installation site should also permit easy removal of

the welding machine outer enclosure for maintenance

functions.

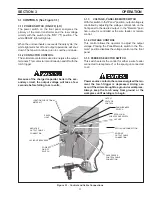

CAUTION:

Do not place any filtering device over the

intake air passages of the welding ma-

chine as this would restrict the volume of

intake air and thereby subject the welding

machine internal components to an over-

heating condition and subsequent failure.

Warranty is void if any type of filtering

device is used.

If a forklift vehicle is used for lifting the unit, be sure that

the lift forks are long enough to extend completely under

the base.

2.1.1 LIFTING EYEBOLT

To install lifting eyebolt furnished with the power source,

proceed as follows.

A. Remove the hole plug from the nut in the cover.

B. Install the eyebolt and fully tighten with a suitable

tool.

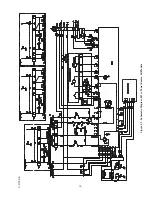

Customers Fused Line

Disconnect Switch

(See Table 2.1 for

recommended fuses)

Figure 2.1 Primary Voltage Diagram