SECTION 5 TROUBLESHOOTING

16

5.1 GENERAL TROUBLESHOOTING

If welding equipment doesnt work right despite compli-

ance with checklist inspect as follows:

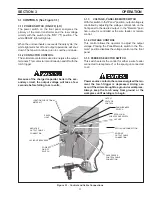

A. With all power controls ON and other operating

controls at required settings, visually check all power

cables and connections for evidence of overheating

or sparking.

To avoid shock, do NOT touch electrode wire or

parts in contact with it, or uninsulated cable or

connections.

B. Isolate trouble to one part of the welding installation:

primary power supply, power source, Feeder or wire

guide train (casing, drive rolls, liners and contact tip).

If this inspection indicates trouble in the Feeder, use

Troubleshooting Guide, in the feeder manual.

Many troubleshooting situations require that the

power remain On and that power terminals in the

equipment carry voltage. Exercise extreme caution

when working on LIVE equipment. Avoid contact

with electrical components, except when testing

with an appropriate instrument.

Do not make any repairs to equipment unless you are

fully qualified, as described in the maintenance sec-

tion.