SECTION 5 TROUBLESHOOTING

17

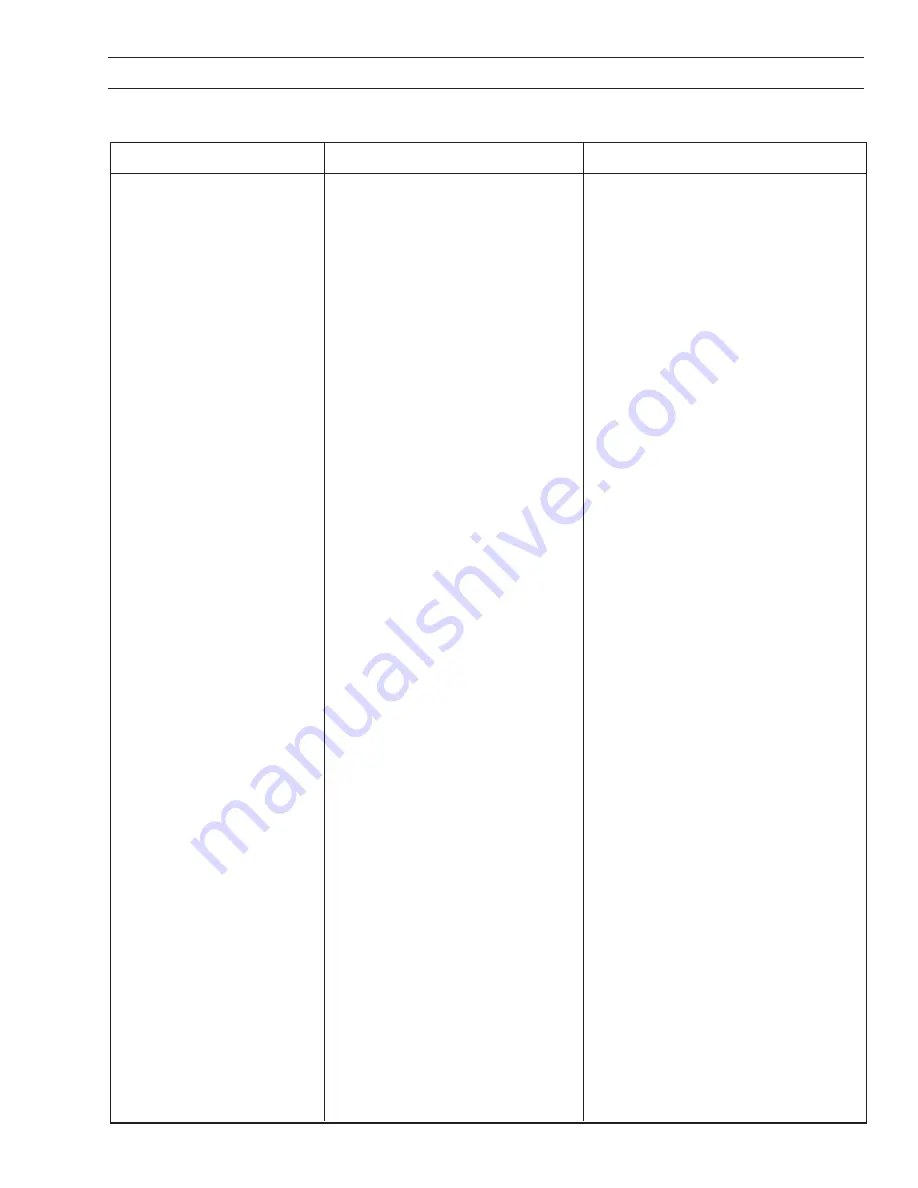

TABLE 5.1 TROUBLESHOOTING GUIDE

WELD CONDITION

POSSIBLE CAUSE

REMEDY

1. No weld or control power.

a. Primary input power not available.

a. Check for Voltage at primary input.

b. Faulty connection, primary input

b. Repair or replace cable or switch

cable, or power switch

as necessary.

c. Blown line fuse.

c. Replace fuse. If it blows again,

contact ESAB representative.

2. No welding power.

a. Thermostat has opened.

a. Wait 15 minutes with fan running. If

still no power, contact ESAB repre-

sentative.

b. Shorted S.C.R. in main rectifier.

b. Check S.C.R. and replace if reqd.

c. Open in wiring

c. Check all wiring.

3. Fan does not run. No

a. See Weld Condition 1.

a. Repair or replace cable or switch

problem - thermostatically

as necessary.

controlled fan.

b. Defective fan motor (MTR1)

b. Replace fan motor (MTR1).

4. Erratic welding current.

a. Poor workpiece connection.

a. Check workpiece connection.

b. Loose welding connections.

b. Check all connections.

c. Wrong polarity.

c. Check for correct polarity.

5. Welding output Voltage

a. Low line Voltage.

a. Use correct voltage.

and/or current too low.

b. Welding cables too long or too

b. Use correct cable size.

small.

c. Loose connection.

c. Check all welding cable

connections.

d. Defective capacitor bank.

d. Check capacitors for low

leakage resistance.

6. Stringy irregular bead,

a. Torch moved too fast.

a. Move torch slower along seams.

poor penetration.

b. Controls are not set properly for

b. Reset control properly.

metal gauge thickness.

c. Wrong polarity.

c. Check for correct polarity.

7. Bead not centered.

a. Nozzle not aligned.

a. Move torch nozzle parallel to

and centered over seam.

8. Bead too large.

a. Torch moved too slowly.

a. Move torch faster along seam.

9. Unstable arc, excess

a. Incorrectly set controls.

a. Reset controls.

spatter, weld porous.

b. Shield gas flow is too low or

b. See Condition 10.

stopped.

c. Torch nozzle is too far from work.

c. Maintain 1/4" (6 mm) wire

tip to work; hold closer to work.

d. Faulty regulator or adapter.

d. Check flow at outlet;

replace faulty item.

e. Faulty gas solenoid valve.

e. Replace solenoid valve.

f. Wrong polarity.

f. Check polarity.