22

Maintenance And Service

4.

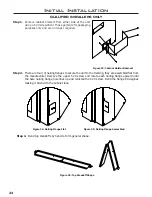

Convert the existing pilot orifice using a 7/16 inch wrench. Loosen the pilot head, rotate counter clockwise

and fully remove. Remove the existing orifice and replace with the one supplied in the kit (Figure 31). Re-

install the pilot head and tighten back to its original position (Figure 32)

6. Reinstall burners, log grate, burner media, logs, and glass door (see

m

aIntenance

anD

s

erVIce

section of

Owner’s Manual

).

7. Purge any air from gas line and reconnect to unit.

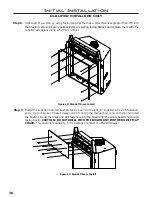

8. Use a small brush and apply a warm soapy water solution to all gas connections. If a gas leak is present,

bubbling will occur. Gas leaks can be repaired by using a gas approved pipe thread sealant. WARNING:

NEVER USE AN OPEN FLAME WHEN TESTING FOR GAS LEAKS

9. Reconnect electrical power to the unit.

10. Light the pilot and recheck for leaks in the aluminum pilot line. If a leak is evident, contact your ENVIRO

dealer for a pilot line replacement.

WARNING: DO NOT ATTEMPT TO FIX THIS LINE, IT MUST BE

REPLACED IF DAMAGED. The pilot should properly cover the thermocouple. If adjustment is necessary,

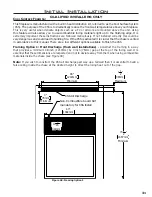

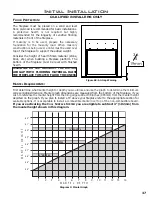

In the USA: The appliance may be installed at higher altitudes. Please refer to your American Gas Association

guidelines which state: the sea level rated input of Gas Designed Appliances installed at elevations above

2000 (610 m) feet is to be reduced 4% for each 1000 feet (305 m) above sea level. Refer also to local

authorities or codes which have jurisdiction in your area regarding the de-rate guidelines.

In Canada

: When the appliance is installed at elevations above 4500 feet (1372 m), the certified high altitude

rating shall be reduced at the rate of 4% for each additional 1000 feet (305 m).

turn the adjustment screw in the valve (see Figure 32) clockwise to decrease and counter-clockwise to increase

until the correct flame is achieved.

11. Start the main burner and verify full range of adjustment using the UP/DOWN key. Confirm the inlet and

manifold gas pressures are within the acceptable range using a manometer (see I

nItIal

I

nstallatIon

- g

as

l

Ine

c

onnectIon

anD

t

estIng

).

If this unit has been installed at an altitude higher than 2000ft (610m) it is

required to de-rate the unit accordingly.

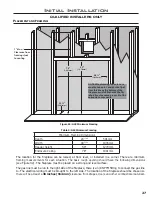

Figure 31: Pilot Orifice

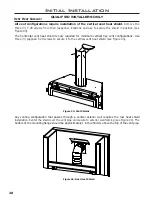

Figure 32: Correct Pilot Position

12.

MAKE SURE

that the conversion labels provided are installed on or close to the rating label to signify

that the unit has been converted to a different fuel type.

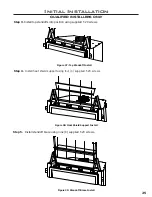

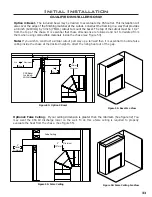

5. Convert the gas valve:

a) Remove the existing stepper motor using a T20 screwdriver.

b) Remove the rubber diaphragm and spring within; do not reuse.

c) Install the new stepper motor with integrated diaphragm assembly using longer hardware.

d) Plug new motor into existing wiring harness.