14

www.enelx.com

Phone: +1-844-584-2329

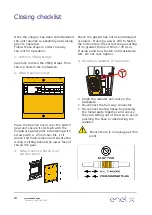

Removing the radiator from the base of

the JuicePump gives more space for

bringing power into the unit, however,

removing the radiator is not always

required. Assess the situation on site.

5. Remove radiator (optional)

Unscrew the 4x nuts using an 8mm nut

driver to remove the radiator. Pull the

radiator off the fasteners, and sit the

radiator on the base plate.

Reach behind and unclip the four way

connector.

The four way connector is the left hand

plug attached to the underside of the

unit. Squeeze front clip and pull down to

release.

3. Remove front and rear radiator

panels

If access to the rear radiator panel is

difficult, the internal radiator may be

removed to access the rear base fixing

points. If so, remove the front radiator

panel only, and go to item 5.

Unscrew the 8x security screws and

remove them and the washers from both

radiator panels using the 5mm pin hex

tool. Pull the radiator panels away from

the metalwork frame to remove.

4. Remove shipping bolts

Unscrew the 4x bolts from the shipping

base to disengage. 16mm socket

required.

Note: Keep the plastic inserts from the

bolts for later use.

Unpacking & installation preparation

Содержание JuicePump

Страница 1: ...50kW DC RT www enelx com Phone 1 844 584 2329 Installation Manual TRI93 50 01 UL ...

Страница 2: ......