1. Remove: Mains lead - Sewing foot - Machine base - Needle plate.

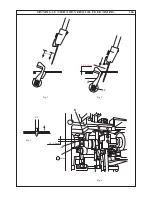

2. Make sure that there is no axial play on chain looper shaft

"a"

. If necessary, adjust with

stop collar inside shaft

"g"

in Fig.6 in page 11c.

3.

Angular position of chain looper:

Insert a new needle (No 90) in

"L2"

. Check height

and orientation of needle bar in page 5. Bring chain looper to its far right swing position.

Check distance from point of chain looper to chain needle with thickness of gauge. If

necessary, loosen screw

"c"

just enough to adjust the chain looper arm

"d"

angularly to

obtain a clearnace of

1.5 to 1.8mm

. Then tighten screw

"c"

.(Fig.1)

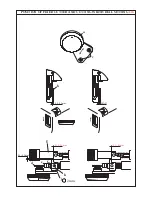

Note: At this step, an easy check of the chain looper timing can be done as follows:

Chain looper motion right to left and the needle bar stroke should start at the same time.

Turn the handwheel towards you, bring the chain looper eye from right to left motion

behind the cover hem needle eye

"L0"

. Check if eye of chain looper matches with eye

of needle (eye to eye).(Fig.2) If not, recheck all the above adjustments and adjust

timing stroke with eccentric

"5"

. See page 3a & 3b for the position of eccentric. The

eccentric

"5"

is used for both chain and lower looper timing. When adjusting this

timing, make sure that you also check the adjustment of lower looper stroke.

( See page 6 and 8 )

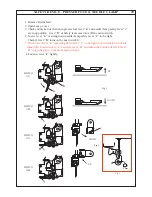

4.

Clearance of chain looper:

Bring point of looper - from right to left - behind the cover

hem

needle

"L2"

, and check if clearance is less than

0.05mm

. Then bring tip of looper

behind the cover hem needle

"L0"

, and check if clearance is less than

0.05m

.(Fig.3)

5. Clearance of chain needle(s) guard: Turn handwheel towards you until coverhem needle(s)

approaches to chain needle guard as close as possible. At this time, the clearance between

coverhem needle(s) and chain needle guard should be less than 0.1 mm. (See Fig. 4). If

necessary, adjust the clearance with screw

"e"

(See Fig. 4) and make sure that the gap

between chain needle guard and the tip of chain looper is set at 1.0

~

2.0 mm. (See Fig. 5).

Note: Make sure that the chain needle

"L0"

is correctly positioned behind the chain looper

in its motion left to right. The

(L0)

needle tip (motion down) should be positioned at

the beginning of the chain looper hump (back of chain looper). See chain looper

orbital motion on Fig.3.

11b

CHAIN LOOPER : ANGULAR POSITION - CLEARANCE - ORBITAL

TIMING - CLEARANCE OF CHAIN NEEDLES GUARD

Содержание 745 -

Страница 1: ...745 845 SERVICE MANUAL 2 2 5 5 1 3 5 NA 6 0 B 1 2 1 T P T P...

Страница 12: ...1a REMOVING MACHINE BASE COVER 1 Remove Mains lead 2 Remove Machine base Unit 1 by loosening screws a a 1 a a...

Страница 18: ...a HEIGHT AND ALIGNMENT OF CLOTH PRESSER BAR 4a 5 b c 4 7mm...

Страница 24: ...TIMING OF LOWER LOOPER 8a A B C D b a 5 2mm R1 Fig 1 Fig 2 Fig 3...

Страница 35: ...MOVING CUTTER AND VERTICAL FEED TIMING 14a R1 A a B d c Fig 2 Fig 4 Fig 3 Fig 1 2mm 0 5 0 5mm 1 0 1 5mm...

Страница 51: ...ANNEX SETTING POSITIONS OF SL DF DIALS b c f d g e 2 1 C B A...

Страница 53: ...d ANNEX SETTING POSITIONS OF SL DF DIALS h i Z k j p SL Dial DF Dial Fig 3 Fig 4 i A n k a Fig 2 view Z view Z...

Страница 61: ...M E M O...