12

Mounting- and Operating Instruction CEAG DualGuard-S

40071860347 January 2020 www.ceag.de

5 Transport, Packaging and Storage

Annual visual inspections:

• Screw connections (check unsecured screw connections

for tight fit)

• Battery installation and accommodation

• ventilation

If block voltages are outside the specified range or if the

surface temperatures of different blocks differ by more than

5 K, customer service should be requested.

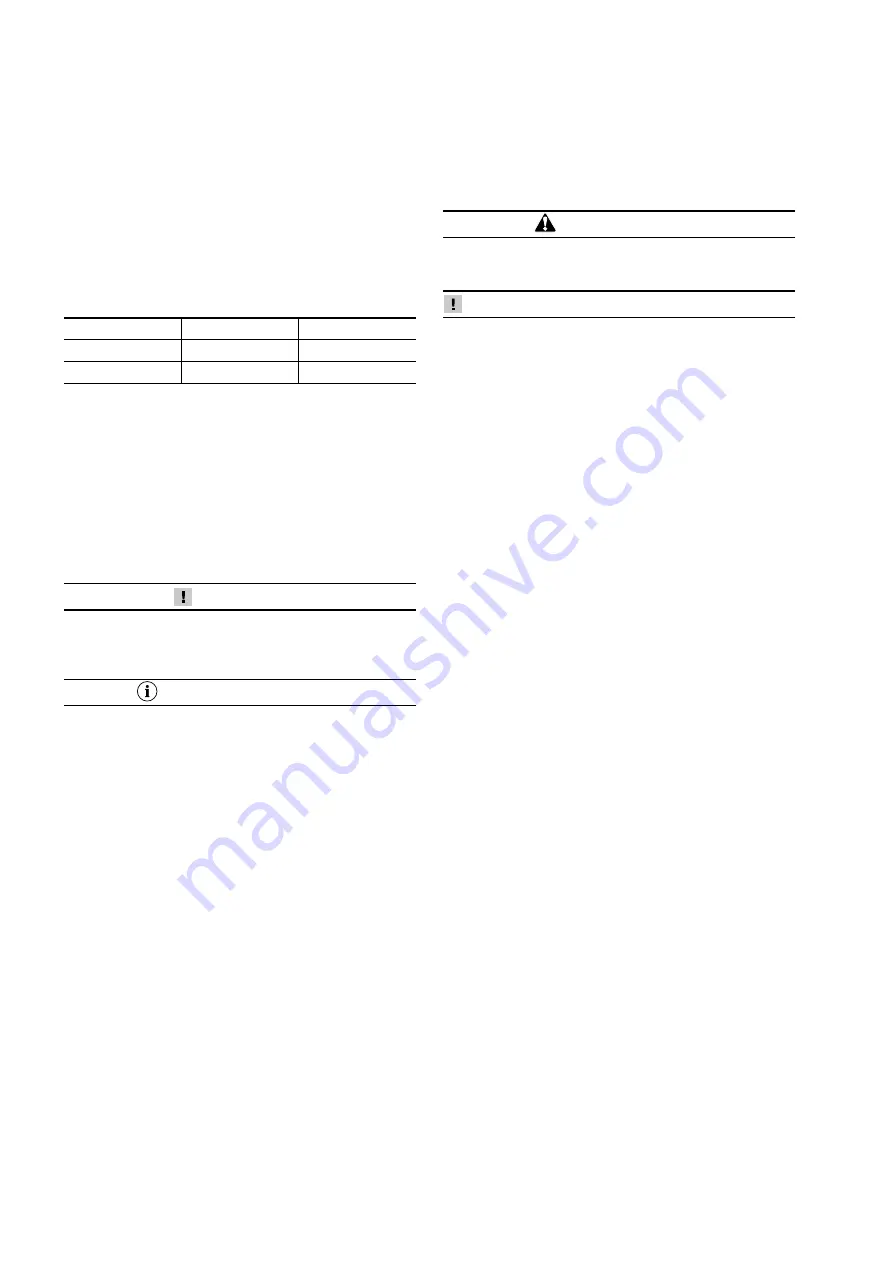

in operation since 6-V-blocks

12-V-blocks

6.81 V

13.62 V

< 6 month

6.60 - 7.19 V

13.33 - 14.16 V

> 6 month

6.64 - 7.16 V

13.38 - 14.11 V

Tab. 7: Permissible range of float charge voltages

4.7 Störungen

Verhalten At Störungen

Hierzu finden Sie in der Montage- and Betriebsanleitung

ZentralBatterysystem entsprechende Angaben.

4.8 Spare parts

Only use original spare parts from the manufacturer.

ATTENTION!

Wrong or faulty spare parts from other manufacturers can

cause serious damage to the battery. Ensure the same char-

ging state when changing the battery blocs.

RECOMMENDATION:

not more than 25% of the battery packs of a battery set

should be replaced. Therefore with 18 packs not more than

5 packs should be replaced.

When 50% of the expected service life is exceeded and

single battery packs fail, the complete set should be replaced

4.9 Ordering Spare Parts

Please state the following when ordering spare parts:

• order number

• rated capacity

• Typee

In case of complaints you need a RMA - number from us. For

further information see www.ceag.de!

5 Transport, Packaging and Storage

SAFETY NOTES!

WARNING! RISK OF INJURY! There is a risk of injury when

transporting or loading due to falling parts.

ATTENTION! DAMAGE TO PROPERTY!

Batterys will be destroyed or damaged by improper transport.

The following safety instructions must therefore always be

observed:

• Never lift loads over persons.

• Always move the device with the greatest care and caution.

• Only use suitable slings and hoists with sufficient load-

bearing capacity.

• Always transport and store the DualGuard-S system upright

(markings and tilt indicator on the packaging).

• Avoid ingress of dust and moisture during transport.

• Ensure that all transport routes are clear (sufficient width

and clear height for all transport movements). Sufficient

space is available for people to move aroand if loads tilt or

slip. Have sufficient load-bearing capacity (for load, pak-

kaging and means of transport). The means of transport

used cannot be overstrained with regard to gradients and

the nature of the subsoil.

• Only use means of transport (e.g. lift trucks, forklift trucks,

etc.), slings (traverses, chains, ropes, etc.) and securing

devices (wedges, squared lumber, guide, tensioning, se-

curing ropes, etc.) in perfect technical condition and with

sufficient load-bearing capacity.

• Observe all instructions regarding transport conditions,

transport position, attachment points on the transport

packaging or on the device / switch cabinet.

For the execution of transport work, use only personnel who

are familiar with the usual methods and signals and are able

to carry out the transport work professionally, safely and in

accordance with the risks involved.

5.1 Transport inspection

Check delivery immediately upon receipt for completeness

and transport damage. In case of externally recognizable

transport damage, do not accept the delivery or accept it

only ander reservation.

5.2 Packing

If no return agreement has been made for the packaging,

separate materials by Typee and size and return them for

further use or recycling.