28

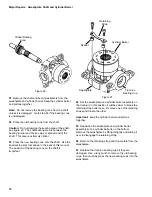

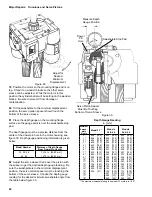

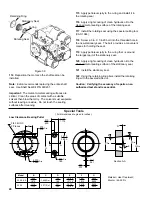

Retaining Ring

Stationary Seal

O-ring

Figure 39

Rotating Seal

115 Apply petroleum jelly to the o-ring and install it in

the rotating seal

116 Apply a light coating of clean hydraulic oil to the

cleaned metal sealing surface of the rotating seal.

117 Install the rotating seal using the special pulling tool

(CAS 1844).

118 Screw a 3 in. X 1/4-20 bolt into the threaded hole in

the new stationary seal. The bolt provides a convenient

means for holding the seal.

119 Apply petroleum jelly to the o-ring that is around

the largest part of the stationary seal.

120 Apply a light coating of clean hydraulic oil to the

cleaned metal sealing surface of the stationary seal.

121 Install the stationary seal.

122 Using the retaining ring pliers install the retaining

ring with the beveled side out.

Caution: Verifying the accuracy of repairs on an

authorized test stand is essential.

114 Reposition the motor so the shaft seal can be

installed.

Note: Eaton recommends replacing the entire shaft

seal. Use Shaft Seal Kit P/N 990231.

Important: The metal-to-metal sealing surfaces are

critical. Clean the areas of contact with a suitable

solvent then blow them dry. The solvent must evaporate

without leaving a residue. Do not touch the sealing

surfaces after cleaning.

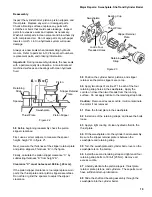

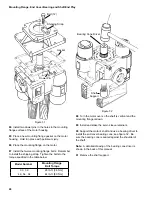

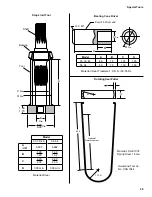

Low Clearance Bearing Puller

Model

B

C

D

E

F

G

33, 39, 46

1.050

1.070

1.565 Ref.

1.35

1.29

12

°

-45'

13

°

-15'

1.907

1.913

2.020

2.026

54, 64

1.115

1.135

2.071 Ref.

.131

.125

10

°

-5'

10

°

-35'

2.310

2.316

2.432

2.438

Material / Heat Treatment;

Stentor / 45-55 Rc

Special Tools

( All dimensions are given in inches.)

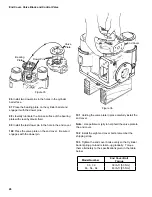

B

.375

.378

A

A

H

Dia.

.510

.490

1.135

1.115

4.010

3.990

Dia.

.740

.760

Dia.

3/8-16 UNC

2 Places

3.510

3.490

.021

.041

.052

.072

Section A-A

Dia.

C

D

E

F

G

Dia.

Dia.

E

E

Содержание 1 Series

Страница 31: ...31 Notes...