19

Reassembly

Inspect the cylinder barrel, pistons, piston slippers, and

thrust plate. Replace any worn or damaged parts.

Check all mating surfaces; replace any parts with

scratches or burrs that could cause leakage. Inspect

parts for excessive wear and replace as necessary.

Wash all metal parts in clean solvent and blow them dry

with compressed air. Do not wipe parts dry with paper

towels or cloth. Lint in a hydraulic system will cause

damage.

Always use new seals when reassembling hydraulic

motors. Refer to parts list 6-132 for seal part numbers,

replacement parts, and ordering information.

Important: During reassembly lubricate the new seals

with a petroleum jelly like Vaseline. Also lubricate all

machined surfaces and bearings with clean hydraulic

fluid.

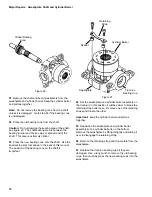

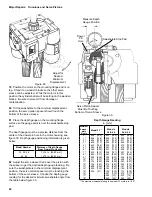

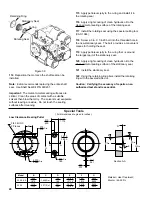

Slipper Retainer

Plate

Retaining

Strap

Spacer

Piston

Swashplate

Piston Slipper

Thrust Plate

Figure 22

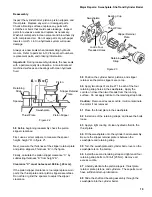

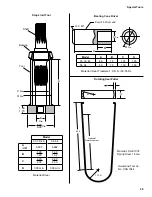

58 Before beginning reassembly check the piston

slipper clearance:

First, use a vernier calipers to measure the spacer

height, height “A” in figure 21.

Next, measure the thickness of the slipper retainer plate

and piston slippers, Thickness “B” in the figure.

Finally, calculate the piston slipper clearance “C” by

subtracting thickness “B” from height “A”.

Clearance “C” must not exceed .008 in. [,20 mm].

If the piston slipper clearance is too large replace worn

parts: the thrust plate and/or piston slipper assemblies.

Do not file or grind the spacers to adjust the slipper

clearance.

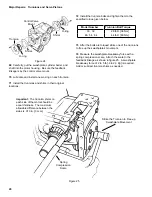

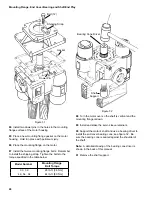

59 Position the cylinder barrel, pistons, and slipper

retainer so the piston slippers are on top.

60 Apply two drops of Loctite 271 in each of the four

retaining strap holes in the swashplate. Apply the

Loctite on closer than two threads from the running

surface. Do not apply loctitie to the retaining strap bolts.

Caution: Remove all excess Loctite, it will contaminate

the motor if not removed.

61 Place the thrust plate in the swashplate.

62 Install one of the retaining straps, and leave the bolts

loose.

63 Apply a light coating of clean hydraulic fluid to the

thrust plate.

64 Fit the swashplate onto the cylinder barrel assembly.

Be sure the slipper retainer plate is between the

swashplate and retaining strap.

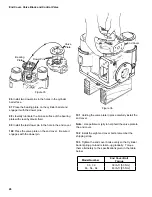

65 Turn the swashplate and cylinder barrel over so the

swashplate is on the bottom.

66 Install the second retaining strap and tighten all four

retaining strap bolts to 18 lb-ft [25 Nm]. Remove all

excess Loctite.

67 Liberally lubricate the piston slippers, thrust plate,

retainer plate, pistons, and cylinders. These parts must

have sufficient start-up lubrication.

68 Slide the shaft and bearing assembly through the

swashplate into the cylinder barrel.

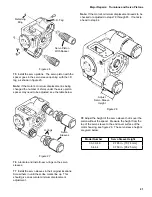

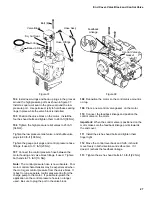

Swashplate

Thrust Plate

Slipper Retainer

Plate

Loctite Four

Threaded Holes

Figure 23

Bearing Cup

Retaining

Strap

Major Repairs: Swashplate, Shaft and Cylinder Barrel

Содержание 1 Series

Страница 31: ...31 Notes...