10

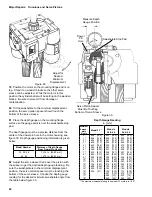

Low Pressure

Relief Valve

High Pressure

Relief Valve

Gauge Port

Plugs

Valve

Block

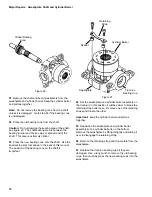

13 Remove the gauge port plugs and o-rings.

Figure 5

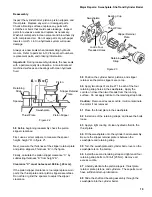

Figure 6

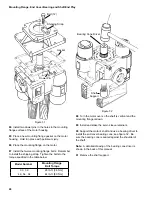

Spool

Shuttle Valve

Plug

Valve Block

Shuttle Valve

Spring

Shuttle Valves

14 Remove the shuttle valve plugs and o-rings.

15 Remove the shuttle valve springs, spool, and valves.

16 Wash the relief valves, plugs, and shuttle valve in

clean solvent. Flush out the valve block. Blow dry the

parts with compressed air. Be sure to blow through the

internal passages of the valve block. Inspect the parts

for damage and replace as necessary.

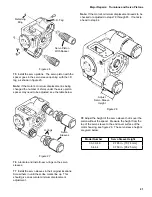

17 Install the relief valves, shuttle valve, and plugs. Use

new o-rings and back-up rings.

Install back-up rings around the small o-rings on the high

pressure relief valves, see figure 4.

Lubricate the new o-rings with petroleum jelly before

installation.

Tighten all plugs and relief valves finger tight. They will

be torqued after the valve block is mounted on the

motor.

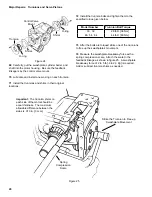

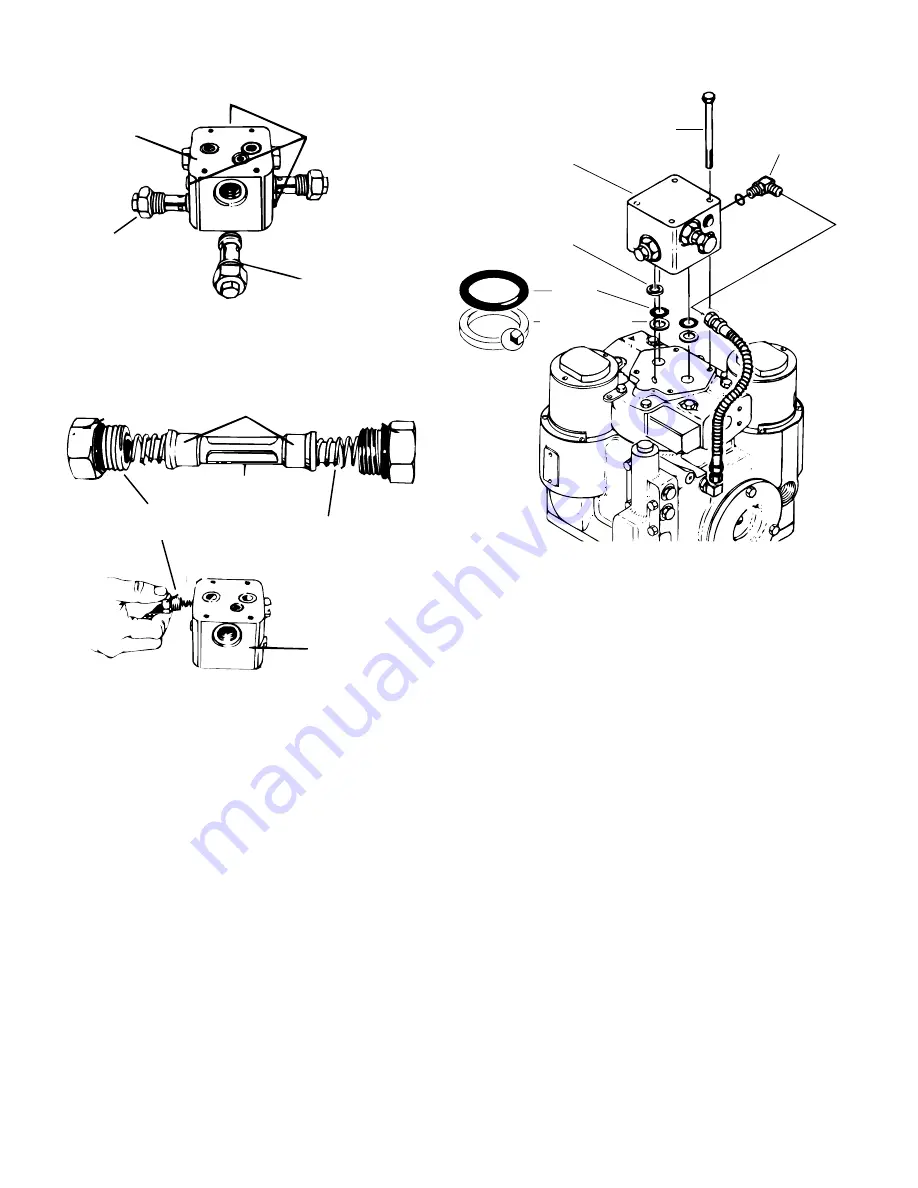

Back-up Ring

O-ring

Sq. Cut Seal

Hose Fitting

Figure 7

Bolt (4)

Valve Block

18 Install new o-rings and back-up rings in the grooves

around the high pressure ports as shown in figure 7.

Install a square-cut seal in the groove around the low

pressure port. Use petroleum jelly to hold these sealing

rings in place while the valve block is installed.

19 Position the valve block on the motor. Install the four

hex head bolts and tighten them to 28 lb-ft [38 Nm].

20 Tighten the high pressure relief valves to 25 lb-ft [34

Nm].

Tighten the low pressure relief valve, and shuttle valve

plugs to 80 lb-ft [108 Nm].

Tighten the gauge port plugs and control pressure fitting,

if used, to 17 lb-ft [23 Nm].

21 Connect the control pressure hose to the valve block

fitting, if used.

Note: The control pressure hose is now obsolete. Poor

motor control characteristics may be experienced when

the motor gets control pressure from the valve block. It

is best to run a separate control pressure line from the

charge pump to the motor. If possible re-plumb the

application so the control pressure hose is no longer

used. Be sure to plug the port in the valve block.

Minor Repair: Valve Block Inspection

Содержание 1 Series

Страница 31: ...31 Notes...