21

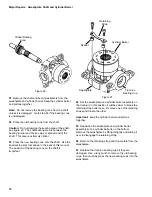

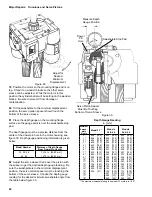

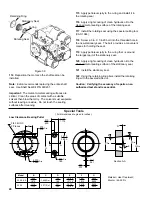

I.D. Tag

Pin

Retaining

Ring

Servo Piston

With Spacer

Figure 26

75 Install the servo pistons. The servo piston with the

spacer goes in the servo sleeve opening with the I.D.

tag, as shown in figure 26.

Note: If the motor’s minimum displacement is being

changed the number of shims under the servo piston

spacer may need to be adjusted, see the table below.

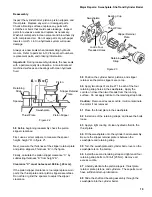

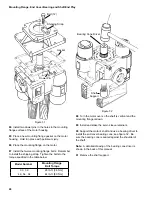

Figure 27

Servo

Sleeves

O-rings

76 Lubricate and install new o-rings on the servo

sleeves.

77 Install the servo sleeves in their original locations.

Screw them in until the scribe marks line up. This

should give an accurate minimum displacement

adjustment.

Note: If the motor’s minimum displacement needs to be

checked or adjusted do steps 78 through 83. If not skip

ahead to step 84.

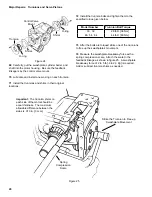

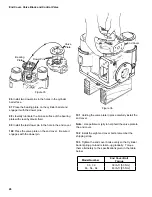

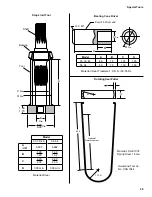

Model Number

Servo Sleeve Height

33, 39, 46

2.785 in. [70,74 mm]

54, 64

3.750 in. [95.25 mm]

78 Adjust the height of the servo sleeve that is over the

piston without the spacer. Measure the height from the

top of the servo sleeve to the end cover surface of the

motor housing, see figure 28. The servo sleeve heights

are given below:

Figure 28

Adjust

Servo Sleeve

Height

Major Repairs: Trunnions and Servo Pistons

Содержание 1 Series

Страница 31: ...31 Notes...