OP000509

Inspection, Maintenance and Adjustment

4-28

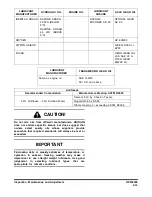

Check Level of Windshield Washer

Liquid

1.

Check fluid level in windshield washer tank, behind

operator's seat.

2.

Open fill cap and add fluid.

NOTE:

Use a washer liquid that is rated for all seasons.

The will prevent freezing during cold weather

operation.

Inspect the Bucket Teeth and Side

Cutters for Signs of Wear

1.

On a daily basis, inspect bucket teeth to make sure

that tooth wear or breakage has not developed.

2.

Do not allow replaceable bucket teeth to wear down to

the point that bucket base edge is exposed. (Figure

29)

NOTE:

These instructions are only for DOOSAN OEM

buckets. If you are using other manufacturers'

buckets, refer to their specific instructions.

Inspect Seat Belt for Proper Operation

Inspect the Structure for Cracks and

Faulty Welds

1.

During the daily walk-around inspection and when

greasing the machine, look for any visible damage to

the machine. Repair or replace any damaged parts

before operating machine.

Check the Operation of All Switches

1.

Verify working condition of all switches before starting

engine.

FG001693

Figure 28

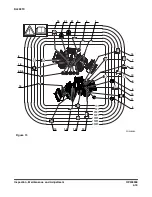

Figure 29

Содержание DL200

Страница 2: ......

Страница 6: ...K1024537E Table of Contents IV ...

Страница 7: ...K1024537E I I Presentation 1Presentation PRESENTATION FG008047 Figure 1 ...

Страница 17: ...OP000506 1 5 Safety 1 3 10 12 6 4 11 5 9 8 3 7 10 9 4 6 2 FG008049 Figure 1 ...

Страница 60: ...OP000506 Safety 1 48 ...

Страница 112: ...OP000507 Operating Controls 2 52 CD Player Optional AST DIR FG000109 Figure 101 ...

Страница 122: ...OP000507 Operating Controls 2 62 ...

Страница 232: ...OP000509 Inspection Maintenance and Adjustment 4 88 ...

Страница 242: ...OP000040 Troubleshooting 6 8 ...

Страница 252: ...OP000510 Specification 7 10 ...