5

Model

Inlet Collar

Diameter (in.)

Footprint

Water

Weight (lbs)

Width [a]

Height [b]

Length [c]

Supply (in.)

Drain (in.)

TY-8000

20

7’-7”

15’-8”

7’-9”

1/4” NPT

2” NPT

4000

TY-10000

20

7’-7”

15’-8”

7”-9”

1/4” NPT

2” NPT

4000

TY-12000

20

7’-7”

15’-8”

7’-9”

1/4” NPT

2” NPT

4000

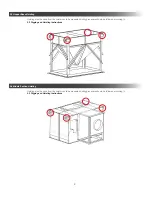

2.1.2 Typhoon Central Dust Collector Dimensions

2.2 Purpose and intended use

2.2.2 Collection of other dry dusts

2.2.1 Collection of explosive dusts

The Typhoon Central Dust Collector is intended to be used to collect a wide range of dust produced in industrial applications. It is particularly effective

for the collection of dusts that are potentially explosive such as light metal dusts (aluminum, titanium, or magnesium) and coal dust, or dusts that are

damp, wet, sticky or oily.

Contact Diversitech support at 1-800-361-3733

for assistance with your application.

The Typhoon Central Dust Collector can also be used to collect dust generated by the working of other metallic and non-metallic

materials that may not present an explosion hazard.

As mentioned, the Typhoon Central Dust Collector is primarily particularly effective for the collection of dust generated by the working of light

metals such as aluminum, titanium, and magnesium, and for the collection of other explosive dusts such as coal dust. Such dusts have the

potential to be highly explosive if not dealt with correctly.

The Typhoon Central Dust Collector neutralizes the threat of a dust explosion by encapsulating the captured dust in water and preventing the

development of both a dust cloud that might reach the explosive limit and of any potential ignition source.

It bears repeating here that the use of a dust collector for the collection of explosive dust is only one part of a safe dust prevention and mitigation

program. Dust shall not be allowed to accumulate or build up on the surfaces of the dust collector, on the air intakes or in the surrounding area.

The owner’s attention is directed particularly to the “Housekeeping” chapter in NFPA 484 (Chapter 7 in the 2015 edition) and in NFPA 654

(Chapter 8 in the 2013 edition).

Содержание Typhoon TY-10000

Страница 26: ...26 12 4 Troubleshooting Procedure...

Страница 29: ...29 NOTES...