10

• If not installed immediately, the equipment shall be retained and stored in a protective environment until immediately prior to

installation. This environment shall be clean, dry, and temperature and humidity-controlled.

• At all times the equipment shall be protected from exposure to weather and from standing water.

• All equipment shall be stored on its original shipping pallet so that it is elevated above grade.

• The equipment shall be clearly labelled and be stored in a location that is easily and readily accessible.

• If prolonged storage (greater than 30 days) is anticipated, the equipment shall be covered with plastic to prevent the accumulation of

surface dust and include the following:

• Motor shaft and flanges to be coated with easily removable rust preventative Tectyl No.502-C, or equal.

• Block all openings to prevent rodents and small animals from nesting inside.

• Insert silica gel desiccant in control boxes and motor junction boxes.

• Cover units completely to exclude dirt, dust, moisture, and other foreign materials. If possible, insert motor in strong, transparent plastic

bag. Attach moisture indicator to side of motor, place several bags of silica gel inside, then seal plastic bag. If motor cannot be placed

in plastic bag and relative humidity exceeds 50%, use space heaters to keep motor at least 10F above ambient air temperature.

• Rotate motor shaft at least 10 revolutions every month; re-lubricate bearings after each year of storage.

• Check desiccant bags and rust prohibitive monthly; replace desiccant and recoat with rust preventative as required. Also check

operation of space heaters.

• If the unit has been in use and prolonged storage is anticipated, the unit shall be cleaned on the inside and outside of dust and water

to prevent damage to the interior and exterior of the collector.

SECTION 6 – STORAGE AND PROTECTION

SECTION 7 - SITE PREPARATION

7.1 Locating equipment

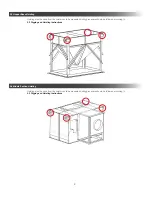

7.2 Foundations and anchor bolts

When locating the Typhoon Central Dust Collector, the design engineer shall consider the many factors associated with site selection including, but

not limited to, seismic design category and site class, environmental conditions, flood design data, design load bearing value of soils, serviceability, risk

category, and load combinations, including dead loads, live loads, snow loads, wind loads, and earthquake loads. Such factors and values are typically

defined by the building codes and standards imposed by the local authority with jurisdiction for buildings and structures.

• The equipment installation, including supports, must be selected and designed to adequately resist all external loads, and combinations of

loads, acting on the equipment at all times.

• Take appropriate precautions to reduce operating equipment noise levels to levels mandated by the relevant legal authorities.

• Take appropriate precautions necessary for all phases of manufacturing, processing, blending, conveying, repackaging, handling and

disposal of hazardous materials as mandated by the relevant legal authorities.

• The Typhoon Central Dust Collector is not intended to be used as a load bearing structure and all connecting components, including ducts,

must be supported separately.

• Provide adequate clear space around the Typhoon Central Dust Collector for access and maintenance.

The foundations supplied must be level and rigid, must fully support the Typhoon Central Dust Collector during operation, and prevent vibration. Refer

to

section 2.1.2

for machine weight. Foundation must be able to support filled operating weight with appropriate safety factor. Sufficient anchor bolts

shall be supplied to connect all Typhoon Central Dust Collector support points. The anchor bolts shall be designed and selected to adequately resist

all forces between the Typhoon Central Dust Collector and the foundation. Note that the Typhoon Central Dust Collector is equipped with a bottom

outlet drain. The foundation for the Arrangement D must be designed to accommodate this drain. See

section 8.2

for further details.

Содержание Typhoon TY-10000

Страница 26: ...26 12 4 Troubleshooting Procedure...

Страница 29: ...29 NOTES...