ADJUSTMENTS

28

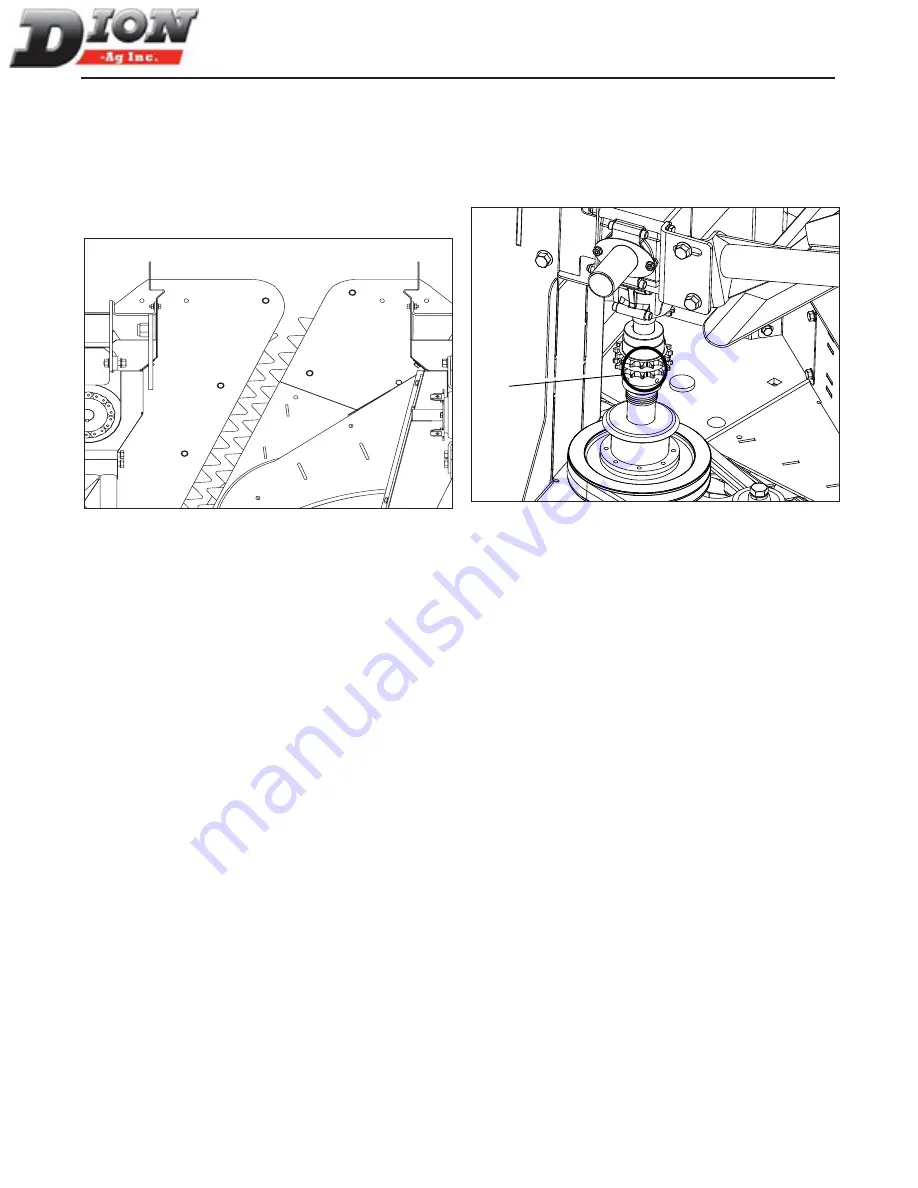

CHAIN SYNCHRONIZATION

FIGURES 38 AND 39

When a new conveyor chain is installed, it is important to

synchronize both conveyor chains. The chains are syn-

chronized when the teeth on both chains are perfectly

centered with one another, as shown in figure 8.

Figure 38 Synchronized conveyor chains

Gears are synchronized at the assembly line.

Synchronization is not required in case of a chain

replacement. Simply install the new chains in the same

position as the old ones. If the chain tension is not

properly adjusted, synchronization may be lost and the

chain could skip a tooth over the drive sprocket. To solve

this problem, simply remove chain tension completely

and move the chain until it reaches the appropriate

position on the sprocket.

When replacing the belts or for any other reasons, it may

be necessary to remove the chain from the couplers

(item 1 figure 39) located underneath the gear boxes. To

easily re-synchronize the conveyor chains, mark with a

line the alignment of the coupler teeth (item 1 figure 39)

1

Figure 39

To synchronize, it is much easier to adjust only the

position of the right vertical shaft. First, slightly loosen

the chain tensioner (item 1, figure 33). With the coupler

chain removed, slowly rotate the right drum in order to

move the right chain forward in relation with the left chain.

It will be easier to achieve this by also removing tension

on the left chain. When the conveyor chain links are well

off-set, check to see if the teeth on the coupler are also

aligned. Rotate the drum until the chain and coupler

teeth are perfectly aligned for a perfect synchronisation.

NOTE

: The synchronisation is satisfactory when the

conveyor chain links are interleaved (figure 38)

and the coupler teeth are well aligned (figure

39).

Manual No.F6418E996E

Содержание F64-90R

Страница 1: ...Manual No F6418E996E...