Installation

www.DaikinApplied.com 29

IOM 1281-2 • CENTRIFUGAL WATER CHILLERS

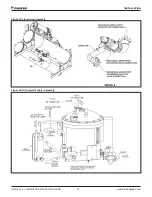

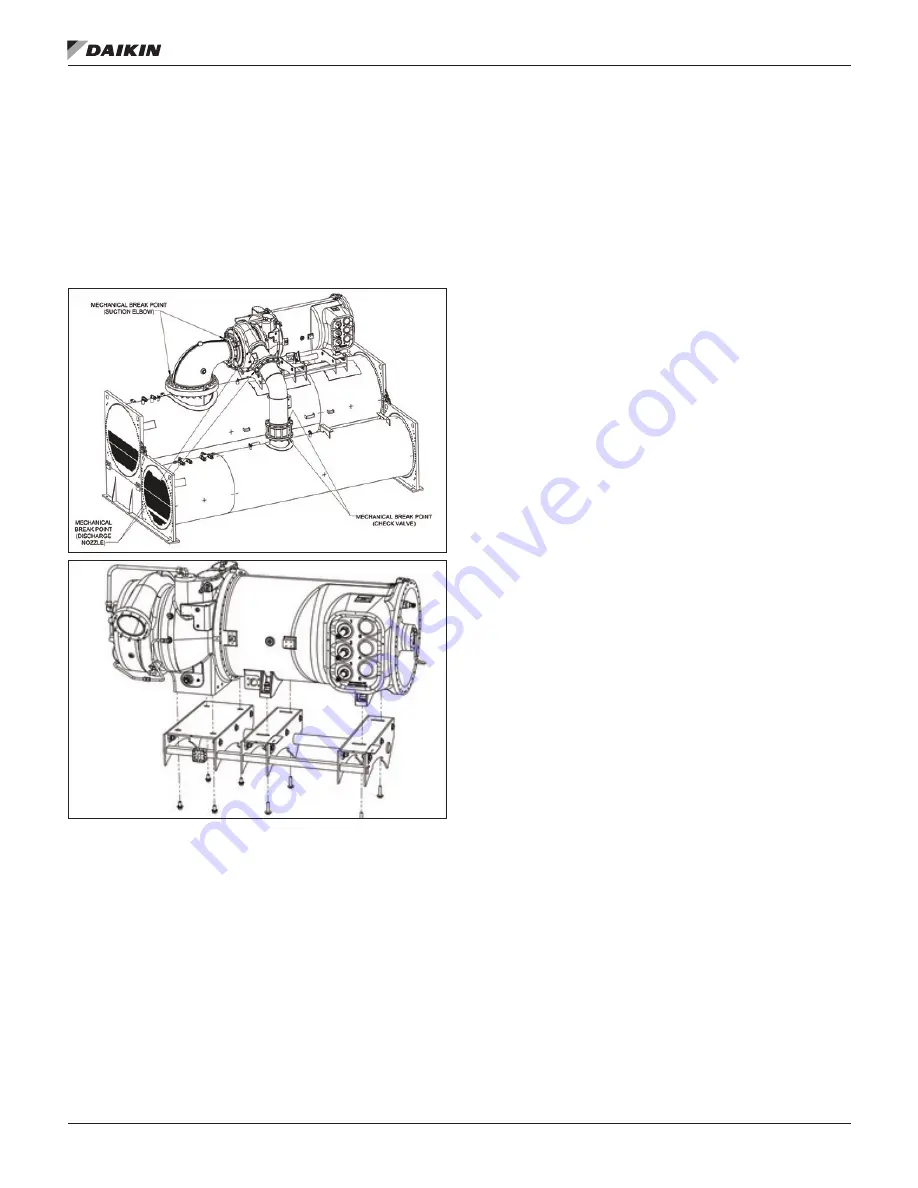

Separating Vessel Stacks

After removing compressor and associated lines for Type

A knockdown, the liquid line connecting the evaporator

and condenser as well as the oil sump would need to be

removed to separate the vessels.

Figure 27

illustrates the

mechanical break points for the liquid line where blockoffs

must be provided on each vessel.

Figure 28

shows the various

connections for oil sump assemblies that need block off caps.

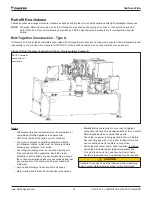

Figure 26: Compressor Removal / Re-Attachment

Unit Reassembly

The level of disassembly required for unit installation will be

varied. For all steps, use new refrigerant gaskets and o-rings

provided.

1.

If the vessels were separated, rejoin them as a first step.

2. The compressor and its suction and discharge piping

should be installed on the vessel stack before any

other lines are attached. Mounting bolts and additional

hardware are shipped as a kit. Leave the mounting bolts

loose until the suction and discharge lines are in place

and aligned. Before tightening the couplings, position

the suction and discharge piping so that the compressor

can be aligned properly. When piping is in the correct

position, secure the compressor mounting bolts and

proceed with installing the couplings using a thin coating

of lubricant.

3. Install the liquid line

4. Install the oil sump and oil cooler lines

5. Install the motor cooling lines

6. Intall the liquid injection line

7. Install hot gas bypass line if applicable

8. Install motor drain lines

9. Install oil eductor line

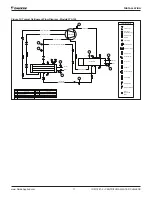

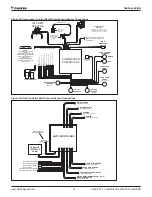

10. Install the electrical wiring and sensor connections as

shown in

Figure 29

.

11. Re-attach all associated power wiring & Ethernet cable.

12. Pull vacuum at evaporator and compressor to 300

microns and perform a standing hold to verify no

moisture or leaks - do not allow rise of 300 microns

within 1 hour.

13. Charge unit with required amounts of refrigerant and

oil and perform refrigerant leak check to ensure all

connections and fittings are securely fastened.

14. Insulate evaporator, compressor, suction line, and other

required areas as necessary.

Содержание WDC

Страница 4: ......

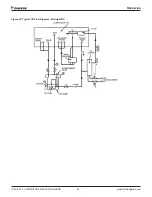

Страница 21: ...Installation www DaikinApplied com 21 IOM 1281 2 CENTRIFUGAL WATER CHILLERS Figure 16 Field Wiring Schematic...

Страница 22: ...IOM 1281 2 CENTRIFUGAL WATER CHILLERS 22 www DaikinApplied com Installation Figure 17 Compressor Control Box...

Страница 23: ...Installation www DaikinApplied com 23 IOM 1281 2 CENTRIFUGAL WATER CHILLERS Figure 18 Unit Control Box...

Страница 38: ...IOM 1281 2 CENTRIFUGAL WATER CHILLERS 38 www DaikinApplied com Operation Figure 39 Unit Detail View Screen...

Страница 72: ......