IOM 1281-2 • CENTRIFUGAL WATER CHILLERS 20 www.DaikinApplied.com

Installation

Field Wiring, Controls & Starters

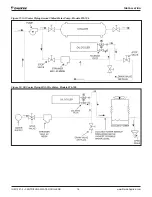

NOTES for Following Wiring Diagram

1. Compressor motor starters are either factory mounted

and wired, or shipped separate for field mounting and

wiring. If provided by others, starters must comply

with the current version of Daikin Applied specification

735999901. All line and load side power conductors

must be copper with ampacity based on 75°C conductor

rating. Exception: For equipment rated over 2000 volts,

90°C or 105°C rated conductors shall be used.

2.

If starters are freestanding, then field wiring between the

starter and the control panel is required. Minimum wire

size for 115 Vac to 220 Vac is 12 gauge for a maximum

length of 50 feet. If greater than 50 feet, refer to Daikin

Applied for recommended wire size minimum. Wire

size for 24 Vac is 18 gauge. All wiring to be installed as

NEC Class 1 wiring system. All 24 Vac wiring must be

run in separate conduit from 115 Vac to 220 Vac wiring.

Main power wiring between starter and motor terminal

is factory-installed when units are supplied with unit-

mounted starters. Wiring of free-standing starter must

be wired in accordance with NEC and connection to

compressor motor terminals must be made with copper

wire and copper lugs only. Control wiring on free-

standing starters is terminated on a terminal strip in the

motor terminal box (not the unit control panel). Wiring

from the unit control panel to the motor terminal is done

in the factory.

3. For optional sensor wiring, see unit control diagram. It is

recommended that DC wires be run separately from 115

Vac to 220 Vac wiring.

4. Customer furnished 24 or 230 Vac power for alarm relay

coil can be connected between UTB1 terminals 84 power

and 86 neutral of the control panel. For normally open

contacts, wire between 82 & 86. For normally closed

contacts, wire between 83 & 86. The alarm is operator

programmable. The maximum rating of the alarm relay

coil is 25 VA.

5.

Remote on/off control of unit can be accomplished by

installing a set of dry contacts between terminals 27 and

21 and remove wire jumper.

6.

Evaporator and condenser flow switches are required.

Thermal dispersion flow switches are installed and wired

from the factory as standard.

7. Customer supplied 24 to 230 Vac, 20 amp power for

optional evaporator and condenser water pump control

power and tower fans is supplied to unit control terminals

(UTBI) 85 power / 86 neutral, PE equipment ground.

8. Optional customer supplied 24 to 220 Vac, 25 VA

maximum coil rated chilled water pump relay (EP 1 & 2)

may be wired as shown. This option will cycle the chilled

water pump in response to chiller demand.

9. The condenser water pump must cycle with the unit. A

customer supplied 24-220 Vac 25 VA maximum coil rated

condenser water pump relay (CP1 & 2) is to be wired

as shown. Units with free cooling must have condenser

water above 60°F before starting.

10. Optional customer supplied 24-220 Vac, 25 VA maximum

coil rated cooling tower fan relays (C1 - C2 standard,

C3 - C4 optional) may be wired as shown. This option

will cycle the cooling tower fans in order to maintain unit

head pressure.

11. For VFD, Wye-Delta, and solid state starters connected

to six (6) terminal motors. The conductors between the

starter and motor carry phase current and selection

shall be based on 58 percent of the motor rated load

amperes (RLA). Wiring of free-standing starter must

be in accordance with the NEC and connection to the

compressor motor terminals shall be made with copper

wire and copper lugs only. Main power wiring between

the starter and motor terminals is factory-installed when

chillers are supplied with unit-mounted starters.

12. Motor current has three selectable options as follows:

0-5V/0- 10V/0- 20mA by build in HMI.

Compressor VFD speed has two selectable options as

follows:0-10V/4 - 20mA.

13. Optional BAS communications modules. The locations

and interconnection requirements for the various

standard protocols are found in their respective

installation manuals, obtainable from the local Daikin

Applied sales office and also shipped with each unit:

Modbus IM 743 LonWorks IM 735 BACnet IM 906

14.

“Full Metering” capability will require some field wiring

when free-standing starters are used. Wiring will depend

on chiller and starter type. Consult the local Daikin

Applied sales office for information on specific selections.

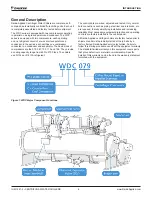

Содержание WDC

Страница 4: ......

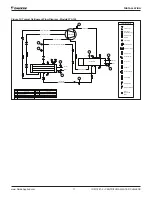

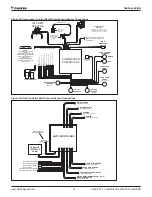

Страница 21: ...Installation www DaikinApplied com 21 IOM 1281 2 CENTRIFUGAL WATER CHILLERS Figure 16 Field Wiring Schematic...

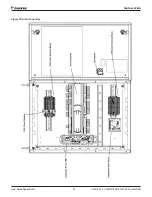

Страница 22: ...IOM 1281 2 CENTRIFUGAL WATER CHILLERS 22 www DaikinApplied com Installation Figure 17 Compressor Control Box...

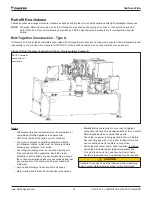

Страница 23: ...Installation www DaikinApplied com 23 IOM 1281 2 CENTRIFUGAL WATER CHILLERS Figure 18 Unit Control Box...

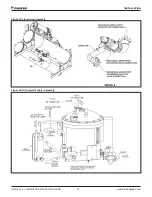

Страница 38: ...IOM 1281 2 CENTRIFUGAL WATER CHILLERS 38 www DaikinApplied com Operation Figure 39 Unit Detail View Screen...

Страница 72: ......