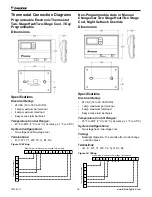

Figure 2: Chassis (Left-hand slope top unit shown)

9.0"

(229mm)

Control Diagram

Compressor/Control Box

Access Cover

Escutcheon Plate

Wiring Diagram

Fan/Coil Section Access Panel

Condensate Line–14" (356mm) Clear Vinyl

Hose Clamp

Air Coil

Water Return

W

ater Supply

Junction Box

Flexible Hoses

Ball Valves

Electric Conduit

5.0"

(127mm)

All Pipe Fittings Are To Be

Field Installed

Water Connections

All piping connections should be made using good

plumbing practices and in accordance with any and all

local codes that may apply.

Note:

It will be helpful to read, “Piping” on page

10

Unit Piping Connection

Each heat pump is supplied with extended copper tubing

on the water-to-refrigerant coil and 1/2" (12.7mm) OD

tubing. The connections are for both the supply and

return water connections.

Note: Valves – Shut off Combination Balancing Valves,

Hoses

– Supply Return, Condensate Drain Hose and

90

º

Elbows are all factory available as accessories, (to

be mounted in the field by others).

Shutoff/Balancing Valve

Each heat pump requires a shutoff valve on both the

supply and return lines for easy serviceability and

removal if it becomes necessary.

We suggest using our combination shutoff/balancing

valves installed in the field between the contractor’s

piping and the heat pump unit. Constructed of brass

and rated at 400 psig (2758 kPa) maximum working

pressure. Valves have a built-in adjustable memory

stop to eliminate rebalancing. The valve installed on the

return line acts as a balancing valve to adjust the proper

water flow. Each shutoff/balancing valve has 1/2" FPT ×

1/2" FPT threaded connections.

Suggested Hose Kit Installation

Field installed piping can be brought up from the floor or

through the wall.

Notes:

1. Hoses are available in multiple lengths to

acommodate various piping locations and

optional components.

2

.

Make sure the pipes fit the confines of the

piping compartment of the heat pump unit.

See Figure 4 on page

9.

Attach the field installed combination shut/off balancing

valve to the building water supply and return piping. Next

add the female pipe adapter connection to unit supply

and return coil connection by sweating them in place

using silver solder.

Next, using the specified hose kit, screw the fixed

end into the shut-off/balancing valve. Remove the

1/2" adapter from the other end of the hose. Insert

the adapter into the female fitting. Using two crescent

wrenches, one to hold the pipe connection and the

second to tighten the adapter, insert the swivel end of

the hose on the adapter and tighten. This completes the

hose connection to standard heat pump equipment.

Adding Motorized & Valve Assemblies

All console water source heat pumps can be field

installed with a motorized valve. All valves are mounted

on the return line of each unit. All valve assemblies

terminate with 1/2" NPT threaded connections and will

also accommodate factory supplied hose kits.

IM 447-11

8

www.DaikinApplied.com

Содержание WAA

Страница 2: ......

Страница 35: ...Notes Comments Form WS CTS 00 01 Rev 4 14 www DaikinApplied com 35 IM 447 11...