t

ypiCal

W

iring

d

iagraMs

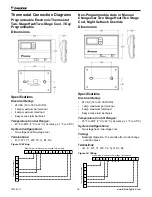

Typical Mark IV/AC

Fan

Motor

070 - Blk

060 - Blk

048 - Red

042 - Blk

036 - Blk

030 - Blk

Compr

Motor

CC - Compressor Contactor

HTR - Crankcase Heater (Optional)

CAP

- Motor Capacitor

Condensate

Sensor

Common Fan

L1

Compressor

Reversing Valve

Solenoid (24 VAC)

0 W

2

G W

1

Y

1 F E L U A P V R C

Mark IV

PC

Board

Hi Pressure

Lo Pressure

Lo

Te

mp

Ground

L1

L2

CC

Heater

Component Layout

1 Compressor Contactor

2 Fan Contactor

3 Transformer

4 PC Board

5 Auxiliary Relay

6 Circuit Breaker

Notes:

1.

Unit is factory wired for 208V operation. If 230V power supply is used, transformer must be rewired by disconnecting the power lead from the red transformerpri-

mary wire and connecting the power lead to the orange transformer primary wire. Place an insulation cap on the red transformer primary wire.

2.

All temperature and pressure switches are normally closed.

3.

Component layout shown below is typical. Some components may not be used on this model or voltage.

4.

Mark IV/AC controller board contains a static sensitive microprocessor. Proper grounding of field service personnel should be observed or damage to controller

may result.

5.

Terminal block on Mark IV/AC board provides 24 VAC at terminals R and C. All other outputs are 24 VDC.

6.

Field supplied relays installed on the input terminals (W1, W2, Y1 or G) may interfere with proper unit operation. Never install relay coils in series with inputs.

7.

For more information pertaining to the Mark IV/AC controller, refer to OM120.

IM 447-11

26 www.DaikinApplied.com

Содержание WAA

Страница 2: ......

Страница 35: ...Notes Comments Form WS CTS 00 01 Rev 4 14 www DaikinApplied com 35 IM 447 11...