SiBE341001

Troubleshooting by Remote Controller

Troubleshooting

196

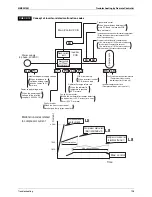

Vacuuming and dehydration procedure

Conduct vacuuming and dehydration in the piping system following the procedure for <Normal

vacuuming and dehydration> described below.

Furthermore, if moisture may get mixed in the piping system, follow the procedure for <Special

vacuuming and dehydration> described below.

<Normal vacuuming and dehydration>

Vacuuming and dehydration

• Use a vacuum pump that enables vacuuming up to 100.7kPa (5 torr, -755 mmHg).

• Connect manifold gauges to the service ports of liquid pipe and gas pipe and run the

vacuum pump for a period of two or more hours to conduct evacuation to -100.7kPa or

less.

• If the degree of vacuum does not reach -100.7kPa or less even though evacuation is

conducted for a period of two hours, moisture will have entered the system or refrigerant

leakage will have been caused. In this case, conduct evacuation for a period of another

one hour.

• If the degree of vacuum does not reach -100.7kPa or less even though evacuation is

conducted for a period of three hours, conduct leak tests.

Leaving in vacuum state

• Leave the compressor at the degree of vacuum of -100.7kPa or less for a period of one

hour or more, and then check to be sure that the vacuum gauge reading does not rise. (If

the reading rises, moisture may have remained in the system or refrigerant leakage may

have been caused.)

Refrigerant charge

• Purge air from the manifold gauge connection hoses, and then charge a necessary

quantity of refrigerant.

<Special vacuuming and dehydration> - In case moisture may get mixed in the piping*

Vacuuming and dehydration

• Follow the same procedure as that for 1) Normal vacuuming and dehydration described

above.

Vacuum break

• Pressurize with nitrogen gas up to 0.05MPa.

Vacuuming and dehydration

• Conduct vacuuming and dehydration for a period of one hour or more. If the degree of

vacuum does not reach -100.7kPa or less even though evacuation is conducted for a

period of two hours or more, repeat vacuum break - vacuuming and dehydration.

Leaving in vacuum state

• Leave the compressor at the degree of vacuum of -100.7kPa or less for a period of one

hour or more, and then check to be sure that the vacuum gauge reading does not rise.

Refrigerant charge

• Purge air from the manifold gauge connection hoses, and then charge a necessary

quantity of refrigerant.

∗

In case of construction during rainy reason, if dew condensation occurs in the piping due

to extended construction period, or rainwater or else may enter the piping during

construction work:

CHECK 8

Содержание RQYQ140-180PY1

Страница 15: ...SiBE341001 Specifications 6 Part 2 Specifications 1 Specifications 7 1 1 Outdoor Units 7 1 2 BS Units 16...

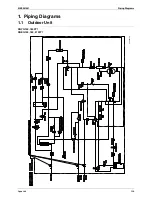

Страница 215: ...SiBE341001 Piping Diagrams Appendix 206 1 Piping Diagrams 1 1 Outdoor Unit RQYQ140 180PY1 RQEQ140 180 212PY1 3d066010A...

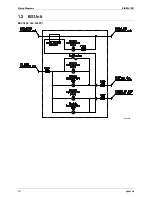

Страница 216: ...Piping Diagrams SiBE341001 207 Appendix 1 2 BS Unit BSVQ100 160 250PV1 4D057985B...

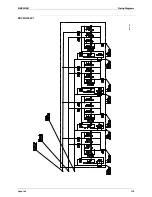

Страница 217: ...SiBE341001 Piping Diagrams Appendix 208 BSV4Q100PV1 3D064148...

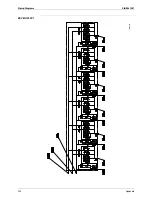

Страница 218: ...Piping Diagrams SiBE341001 209 Appendix BSV6Q100PV1 3D064149...

Страница 220: ...Wiring Diagrams for Reference SiBE341001 211 Appendix 2 2 BS Unit BSVQ100 160 250PV1 3D055928C...

Страница 221: ...SiBE341001 Wiring Diagrams for Reference Appendix 212 BSV4Q100PV1 3D063928B...

Страница 222: ...Wiring Diagrams for Reference SiBE341001 213 Appendix BSV6Q100PV1 3D063929B...

Страница 223: ...SiBE341001 Option List Appendix 214 3 Option List 3 1 Option Lists Outdoor Unit 3D066354...

Страница 224: ...Option List SiBE341001 215 Appendix...