SiBE341001

Troubleshooting by Remote Controller

Troubleshooting

190

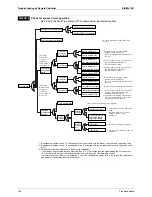

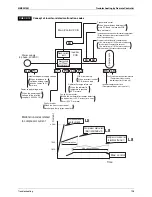

Check for causes of drop in low pressure

Referring to the Fault Tree Analysis (FTA) shown below, probe the faulty points.

CHECK 2

Faulty low

pressure

control

←

Are the electrical characteristics normal?

Abnormally low

low-pressure (Low

evaporating

temperature)

Faulty electronic

expansion valve

control

[In both cooling

and heating]

(See *2.)

[In cooling]

If the indoor unit

electronic

expansion valve is

excessively

throttled: (See *3.)

[In heating]

If the outdoor unit

electronic

expansion valve

excessively

throttled:

(See *4.)

[In cooling]

Low suction

air

temperature

of the

evaporator

[In heating]

Less

circulation

quantity of

refrigerant

Degradation

in condensing

capacity

[In cooling]

(See *1.)

Faulty

compressor

capacity

control

Faulty low

pressure

protection control

Faulty indoor unit

electronic

expansion valve

Faulty

control

Faulty outdoor

unit electronic

expansion valve

Faulty

control

Low suction air

temperature of

indoor unit

Faulty suction air thermistor of indoor unit

Low suction air temperature of outdoor unit

Faulty outdoor temperature thermistor of outdoor unit

High pipe

resistance

Inadequate refrigerant quantity

Moisture choke

Dirty evaporator

Decreased

fan airflow

rate

Decreased

fan output

High air

passage

resistance

Abnormal piping length

Bent or crashed pipe

Clogging of foreign particles

Stop valve closed

Faulty fan motor

Faulty control PCB

(Including capacity setting)

Dirty filter

Obstacle

Faulty low pressure sensor

Faulty control PCB

Faulty low pressure sensor

Faulty hot gas solenoid valve

Faulty control PCB

Faulty valve coil

Faulty valve body

Faulty gas pipe

thermistor of indoor unit

Faulty liquid pipe thermistor

of indoor unit

Faulty control PCB

Faulty valve coil

Faulty valve body

Faulty low pressure sensor

Faulty suction pipe thermistor

Faulty control PCB

Short circuit

Low ambient temperature

←

Is the pressure value checked with the Service Checker

corresponding to the measurement of the pressure sensor?

←

Is the pressure value checked with the Service Checker

corresponding to the measurement of the pressure sensor?

←

Are the electrical characteristics normal?

←

Are the coil resistance and insulation normal?

←

Is the pressure value checked with the Service Checker

corresponding to the measurement of the pressure sensor?

←

Are the coil resistance and insulation normal?

←

Check for the thermistor resistance and

connection.

←

Check for the thermistor resistance and

connection.

←

Is the pressure value checked with the Service Checker

corresponding to the measurement of the pressure sensor?

←

Are the coil resistance and insulation normal?

←

Are the electrical characteristics normal?

←

Check for the thermistor resistance and

connection.

←

Is the suction air temperature not less than 14°C

←

Is the indoor temperature not more than 14°C

←

Is the connector properly connected?

Are the thermistor resistance characteristics normal?

←

Is the outdoor temperature more than -20°C

←

Is the connector properly connected?

Are the thermistor resistance characteristics normal?

←

Is the connector properly connected?

Are the thermistor resistance characteristics normal?

←

Does the piping length fall in the permissible range?

←

Conduct visual checks for pipe conditions.

←

Is there any temperature difference caused

before and after the filter or branch pipe?

←

Eliminate moisture by vacuum operation.

←

Is the heat exchanger clogged?

←

Can the fan motor be rotated with hands?

Are the motor coil resistance and insulation normal?

←

If a spare PCB is mounted, is the

capacity setting properly made?

←

Is the air filter clogged?

←

Is there any obstacle in the air passage?

*1: For details of the compressor capacity control while in cooling, refer to “Compressor PI Control”.

*2: The “low pressure protection control” includes low pressure protection control and hot gas bypass control.

*3: In cooling, the indoor unit electronic expansion valve is used for “superheated degree control”.

*4: In heating, the outdoor unit electronic expansion valve (EVM) is used for “superheated degree control of

outdoor unit heat exchanger”.

←

Check to be sure the stop valve is open.

Содержание RQYQ140-180PY1

Страница 15: ...SiBE341001 Specifications 6 Part 2 Specifications 1 Specifications 7 1 1 Outdoor Units 7 1 2 BS Units 16...

Страница 215: ...SiBE341001 Piping Diagrams Appendix 206 1 Piping Diagrams 1 1 Outdoor Unit RQYQ140 180PY1 RQEQ140 180 212PY1 3d066010A...

Страница 216: ...Piping Diagrams SiBE341001 207 Appendix 1 2 BS Unit BSVQ100 160 250PV1 4D057985B...

Страница 217: ...SiBE341001 Piping Diagrams Appendix 208 BSV4Q100PV1 3D064148...

Страница 218: ...Piping Diagrams SiBE341001 209 Appendix BSV6Q100PV1 3D064149...

Страница 220: ...Wiring Diagrams for Reference SiBE341001 211 Appendix 2 2 BS Unit BSVQ100 160 250PV1 3D055928C...

Страница 221: ...SiBE341001 Wiring Diagrams for Reference Appendix 212 BSV4Q100PV1 3D063928B...

Страница 222: ...Wiring Diagrams for Reference SiBE341001 213 Appendix BSV6Q100PV1 3D063929B...

Страница 223: ...SiBE341001 Option List Appendix 214 3 Option List 3 1 Option Lists Outdoor Unit 3D066354...

Страница 224: ...Option List SiBE341001 215 Appendix...