ESIE98–06A

General Outline

Part 1 – System Outline

1–11

3

1

4

5

1

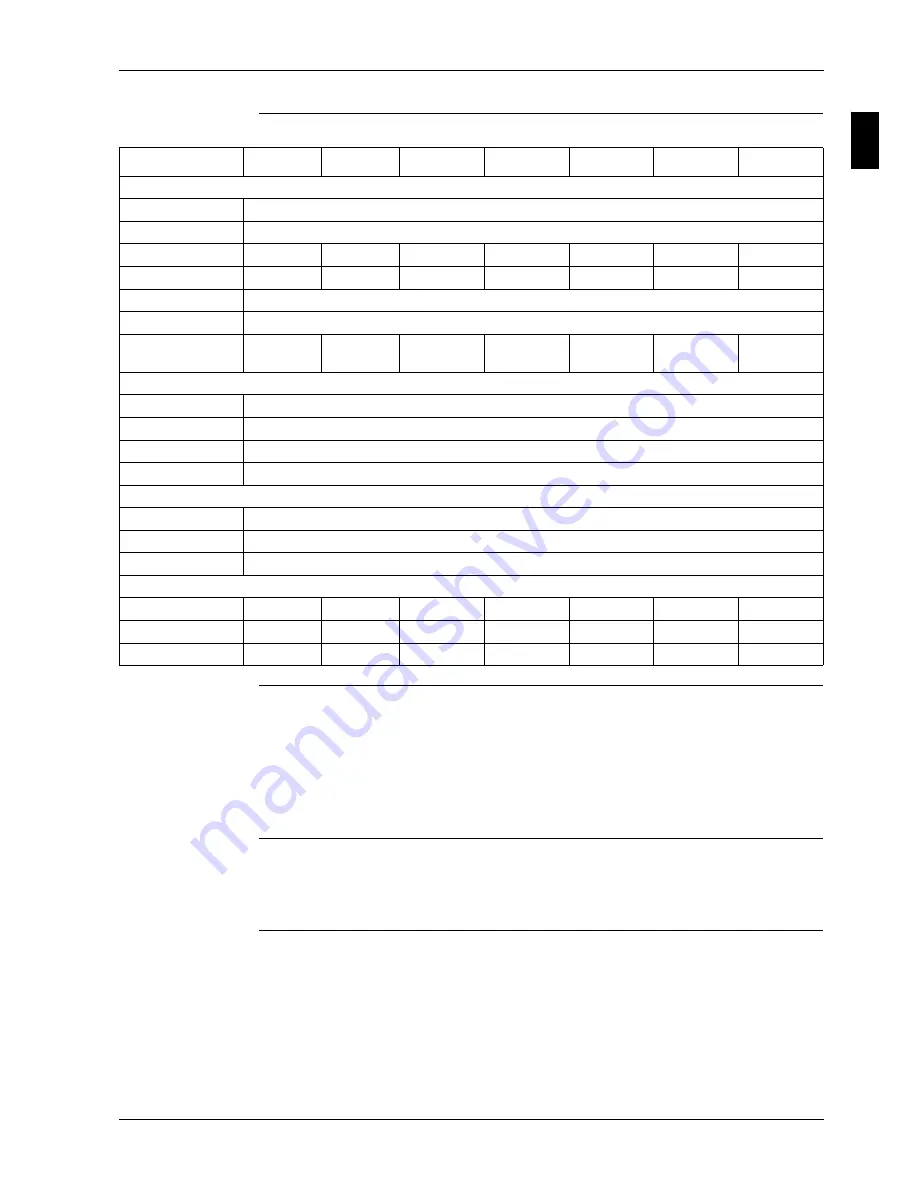

EUWY5-30HB/C

In the following table you will find the electrical specifications of chiller types EUWY5-30HB/C:

Nominal conditions

The nominal conditions are as follows:

■

entering/leaving chilled water temperature 12/7 °C, ambient air temperature 35 °C

■

entering/leaving condenser water temperature 45/50 °C; ambient 7 °CDB/6 °CWB

■

power input is total input:

comp control circuit

■

sound pressure level is measured at a height of 1.5 m and a distance of 1 m in front of the unit.

Operation range

The operation range contains:

■

a leaving evaporator water temperature from 4 °C till 20 °C (pull-down condition till 25 °C)

■

a leaving condenser water temperature from 35 °C till 55 °C.

Model

EUWY5HB

EUWY8HB

EUWY10HB

EUWY15HC

EUWY20HC

EUWY25HC

EUWY30HC

Compressor

phase

3~

Voltage

220 - 380 V

starting current

49 A

79 A

109 A

49 A/109 A

109 A

49 A/109 A

109 A

max. running current

10 A

18 A

21 A

21 A+10 A

2x21 A

2x21 A+10 A

3x21 A

starting method

direct on line

voltage

400 V

nominal running current

5.5 A

9.7 A

12.5 A

5.5 A+12.5 A

2x12.5 A

2x12.5 A+

5.5 A

3x12.5 A

Nominal distribution system voltage

phase

3N~

frequency

50 Hz

voltage

400 V

voltage tolerance

±10 V

Control circuit

phase

1~

recommended fuses

factory installed

voltage

230 V

Unit

nominal running current

8 A

13.2 A

16 A

23 A

31 A

38 A

46 A

recommended fuses

3 x 20 aM

3 x 25 aM

3 x 32 aM

3 x 40 aM

3 x 50 aM

3 x 63 aM

3 x 80 aM

max. running current

12.5 A

21.5 A

24.5 A

36 A

48 A

59.5 A

71.5 A

Содержание EUWA/Y5-30HB/C(Z)

Страница 2: ......

Страница 8: ...Introduction ESIE98 06A vi 3 1 4 5...

Страница 10: ...ESIE98 06A 1 2 Part 1 System Outline 3 1 1 4 5...

Страница 28: ...General Outline ESIE98 06A 1 20 Part 1 System Outline 3 1 1 4 5...

Страница 36: ...Piping Layout ESIE98 06A 1 28 Part 1 System Outline 3 1 1 4 5...

Страница 52: ...ESIE98 06A Wiring Layout Part 1 System Outline 1 44...

Страница 58: ...ESIE98 06A 2 2 Part 2 Functional Description 3 1 2 4 5...

Страница 80: ...The Controller for the EUWA Y5 10HB Z Chillers ESIE98 06A 2 24 Part 2 Functional Description 3 1 2 4 5...

Страница 98: ...The Controller for the EUWA Y15 30HC Z Chillers ESIE98 06A 2 42 Part 2 Functional Description 3 1 2 4 5...

Страница 100: ...ESIE98 06A 3 2 Part 3 Troubleshooting 3 1 3 4 5...

Страница 134: ...Troubleshooting ESIE98 06A 3 36 Part 3 Troubleshooting 3 1 3 4 5...

Страница 136: ...ESIE98 06A 4 2 Part 4 Commissioning and Test Run 3 1 4 5...

Страница 142: ...Pre Test Run Checks ESIE98 06A 4 8 Part 4 Commissioning and Test Run 3 1 4 5...

Страница 146: ...ESIE98 06A 5 2 Part 5 Maintenance 3 1 5 4...