ENGLISH

19

1)

Disconnect DTRON3 from the power mains

2)

Delete any previous associations on COM BOX (9.3.)

3)

Put COM BOX in the association phase (9.3.)

4)

Connect DTRON3 to the power mains

5)

Check the status of the PLC LED on COM BOX; if it is on with a steady light, the association has been successful.

6

CLEANING STORAGE MAINTENANCE

The pump does not require any maintenance. Frost can damage the pump. In very cold temperatures, remove the pump from the

liquid, empty it and store it away from frost. Before any cleaning work is carried out, the pump must be disconnected from the power

mains.

Once the pump has been removed from the liquid, it is advisable to clean the following parts with a simple jet of water:

- Filter (open, see figure 1A)

- Suction filter with float, in case of version X (see figure 3)

- Non-return valve. In this case, remove the part concerned as shown in figure 11.

Be sure to reassemble all parts correctly.

7

TROUBLESHOOTING

Before starting to look for faults it is necessary to disconnect the power supply to the pump (take the plug out of the socket). If the

power cable or any electrical part of the pump is damaged, the repair or replacement must be carried out by the manufacturer or

by their technical assistance service, or by a person with equivalent qualifications, so as to prevent any risk.

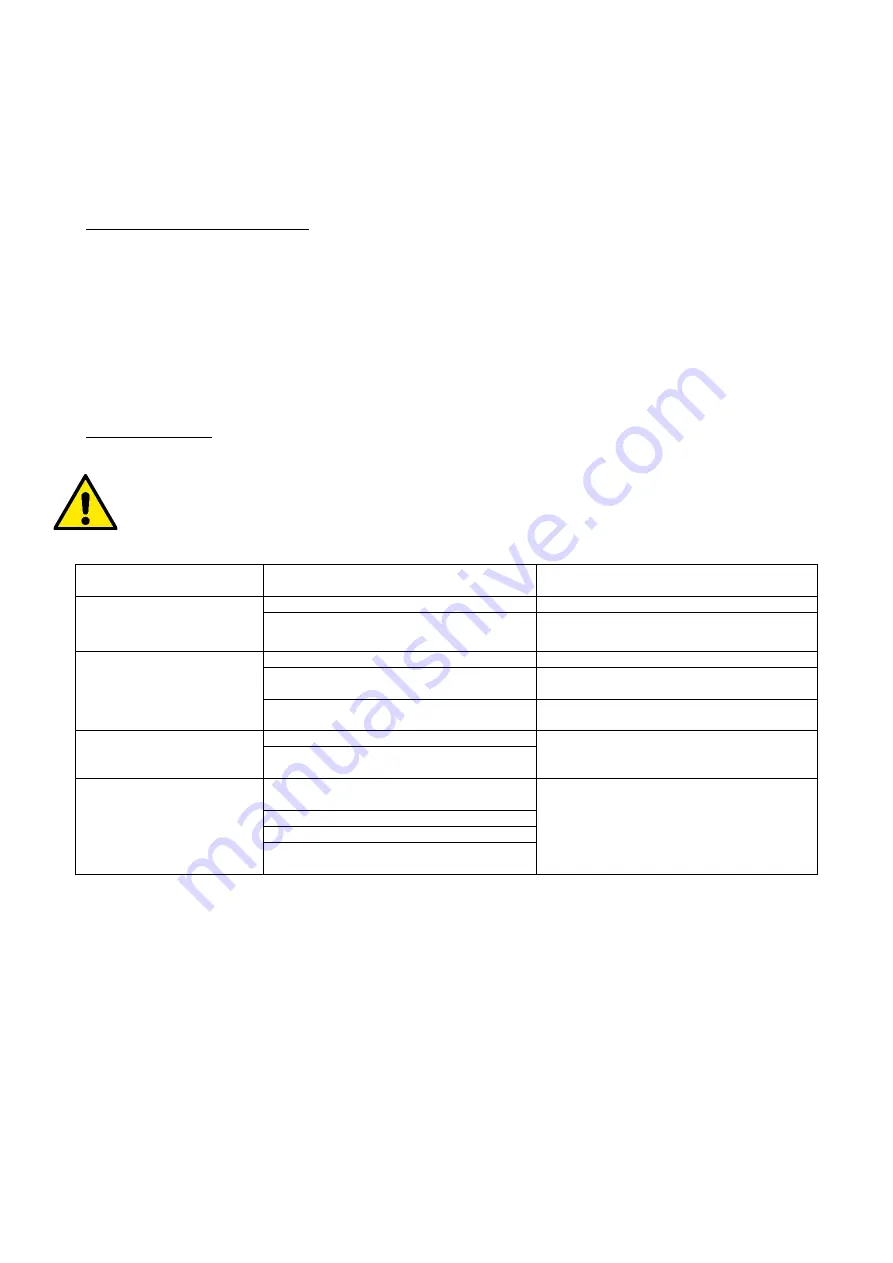

FAULTS

PROBABLE CAUSES

REMEDIES

The pump does not turn on or

does not stay on.

1. Pump is not powered

1. Check power supply

2.. No water

3. Restore the water level

The pump does not deliver water

1. The suction grid or the pipes are blocked

1. Remove the obstructions

2. The impeller is worn or blocked

2. Replace the impeller or remove the blockage

3. The head required is higher than the pump’s

characteristics

The flow rate is insufficient

1. The suction grid is partly blocked

1-2 Remove any obstructions

2. The impeller or the delivery pipe are partly

blocked or encrusted

Pump stops (possible tripping of

the thermal safety switch)

1. The liquid to be pumped is too thick and

overheats the motor.

1-2-3-4 Disconnect the plug and remove the cause

that caused the overheating, wait for the pump to cool

down and reinsert the plug.

2. The water temperature is too high

3. A solid body is blocking the impeller

4. Power supply not in accordance with data plate

values

Содержание DTron 3

Страница 1: ...Fig Fig Image Abb Afb Fig Obr Kuva Fig Fig ekil Rys bra Fig Fig 1 Fig 2 Fig 3 Fig 5...

Страница 2: ...Fig 6 Fig 7 Fig 8 Fig 9...

Страница 3: ...Fig 10 Fig 11 Fig 12...