15 - ENG

D20396

UNIT CYCLES AUTOMATICALLY WHEN POWER IS ON. WHEN DOING MAINTENANCE, YOU MAY BE

EXPOSED TO VOLTAGE SOURCES, COMPRESSED AIR OR MOVING PARTS. PERSONAL INJURIES

CAN OCCUR. BEFORE PERFORMING MAINTENANCE OR REPAIR, TURN OFF AND LOCK OUT

ELECTRIC POWER AND BLEED OFF AIR TANK PRESSURE. NEVER OPERATE THE COMPRESSOR

WITH THE BELT GUARD REMOVED.

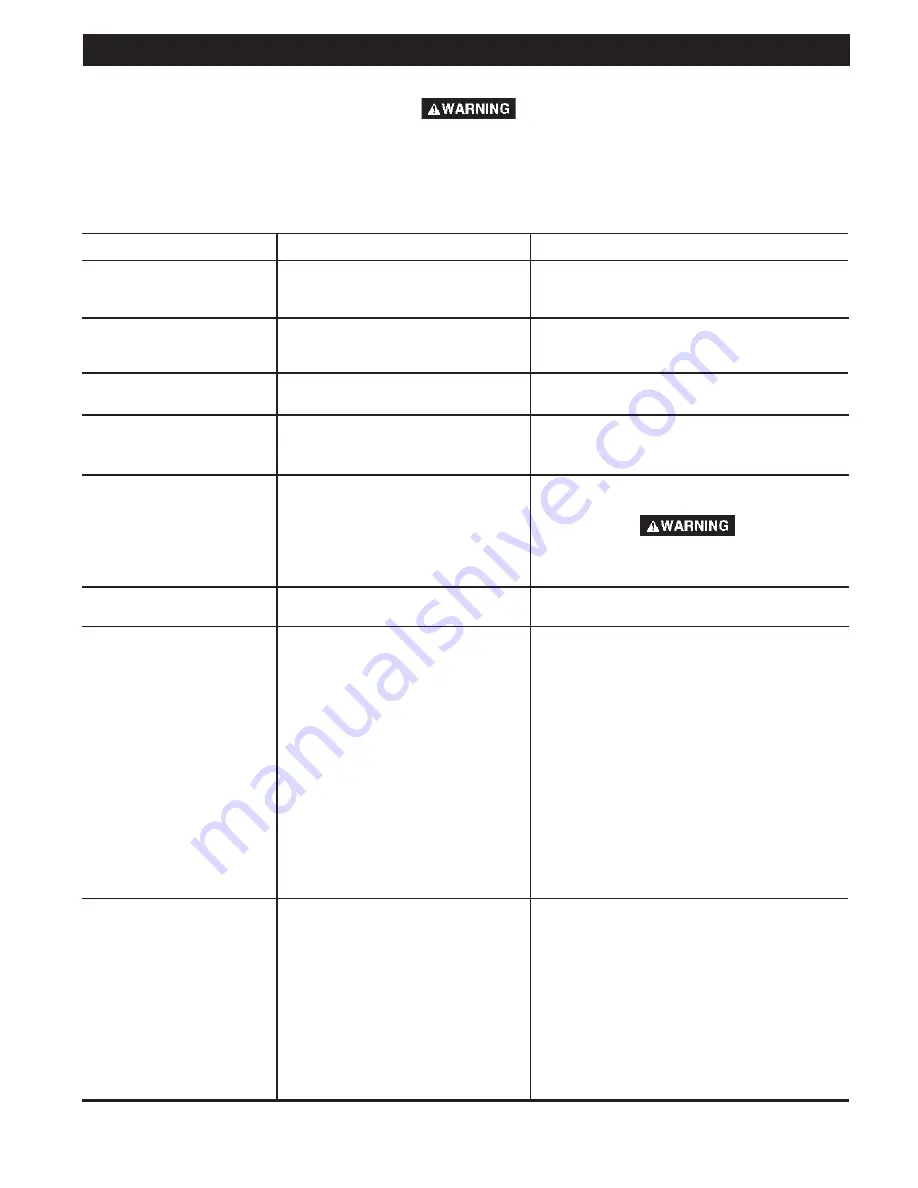

PROBLEM

CAUSE

CORRECTION

Excessive tank pressure - safety

valve pops off.

Unloader valve does not release pressure

when tank reaches "blow-off" pressure.

Unloader valve must be replaced.

Tighten fittings where air can be heard escaping.

Check fittings under soapy water solution.

DO NOT

OVER-TIGHTEN.

Tube or hose fittings are not tight enough.

Air leaks at fittings or hose.

Defective or dirty check valve.

Air leaks inside check valve.

Remove and clean or replace check valve.

DO NOT

OVER-TIGHTEN.

Turn off engine, move unloader valve toggle lever to

vertical position. If air leaks out of tank through

unloader valve, clean or replace check valve.

Defective check valve.

Continuous air leak at unloader

valve.

Air leaks at air tank welds.

Defective air tank.

Air tank must be replaced. Do not attempt repair of

any leaks.

DO NOT DRILL INTO, WELD OR OTHER-

WISE MODIFY AIR TANK. IT WILL BE

WEAKENED.

Possible defect in safety valve.

Air leak from safety valve.

Operate safety valve manually by pulling on ring. If

valve still leaks, it should be replaced.

Defective check valve.

Remove and clean or replace.

Loose pulley.

Tighten pulley set screw.

Low oil level (Compressor or engine).

Maintain prescribed oil level. Add oil

Loose flywheel.

Tighten screw.

Loose compressor or engine mounting

screws.

Check bolts. Tighten as required.

Tension belt per instructions on page 12, step 5.

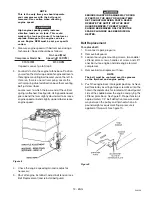

Carbon build-up.

Stiffener bar loose.

Remove the head and valve plate. Clean the valve

plate and the top of the piston. (Be sure carbon does

not fall into the cylinder.) Reassemble to 25-30 ft.lbs.

using new gasket and torque screws.

Check both nuts and tighten if required.

Loose belt.

Knocking noise.

Prolong excessive use of air.

Compressor is not large enough for air

requirement.

Restricted air intake filter.

Loose belt.

Hole in hose.

Check valve restricted.

Air leaks.

Decrease amount of air usage.

Check the accessory air requirement. If it is higher

than the SCFM or pressure supplied by your air

compressor, you need a larger compressor.

Clean or replace air intake filter.

Adjust belt tension.

Check and replace.

Remove and clean or replace.

Tighten fittings. (See Air Leaks section of Trouble-

shooting Guide.)

Compressor is not supplying

enough air to operate accesso-

ries.

TROUBLESHOOTING GUIDE