13 - ENG

D20396

NOTE

This is the only time you should operate

your compressor with the belt guard

removed. Use caution when checking

engine speed.

High engine speeds greatly increase

vibration loads on air tank. This could

weaken the tank and cause it to rupture or

explode. Damage to the engine can also

occur. Engine RPM must be set per specifi-

cation.

2.

Measure engine speed with belt removed using a

tachometer. Speed should be as follows:

No-Load (Max)

Compressor Model No. Speed ( 100 RPM)

919.157251

3700 RPM

If speed is correct go to Step 5.

3.

Four bolts fasten the engine to tank base. Position

yourself on the starter rope side of engine and locate

that engine mounting bolt nearest you on the left. In

this area, there is one vertical spring. Locate the

vertical spring situated directly above the mounting

bolt just described.

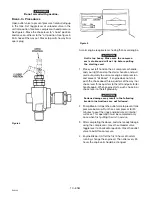

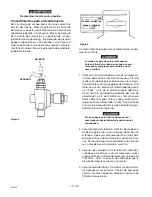

Locate lever to which the lower end of the vertical

spring is attached. See figure 8. Using needle nosed

pliers, bend the lever slightly downward to increase

engine speed or bend slightly upward to decrease

engine speed.

4.

Check the engine speed again and readjust as

necessary.

5.

Shut off engine, install belt, adjust belt tension (see

Belt Replacement) and reinstall belt guard.

Figure 8

SERIOUS INJURY OR DAMAGE MAY OCCUR

IF PARTS OF THE BODY OR LOOSE ITEMS

GET CAUGHT IN MOVING PARTS. NEVER

OPERATE THE OUTFIT WITH THE BELT

GUARD REMOVED. THE BELT GUARD

SHOULD BE REMOVED ONLY AFTER THE

SPARK PLUG WIRE HAS BEEN DISCON-

NECTED.

Belt Replacement

To replace belt:

1.

Disconnect spark plug wire.

2.

Remove belt guard.

3.

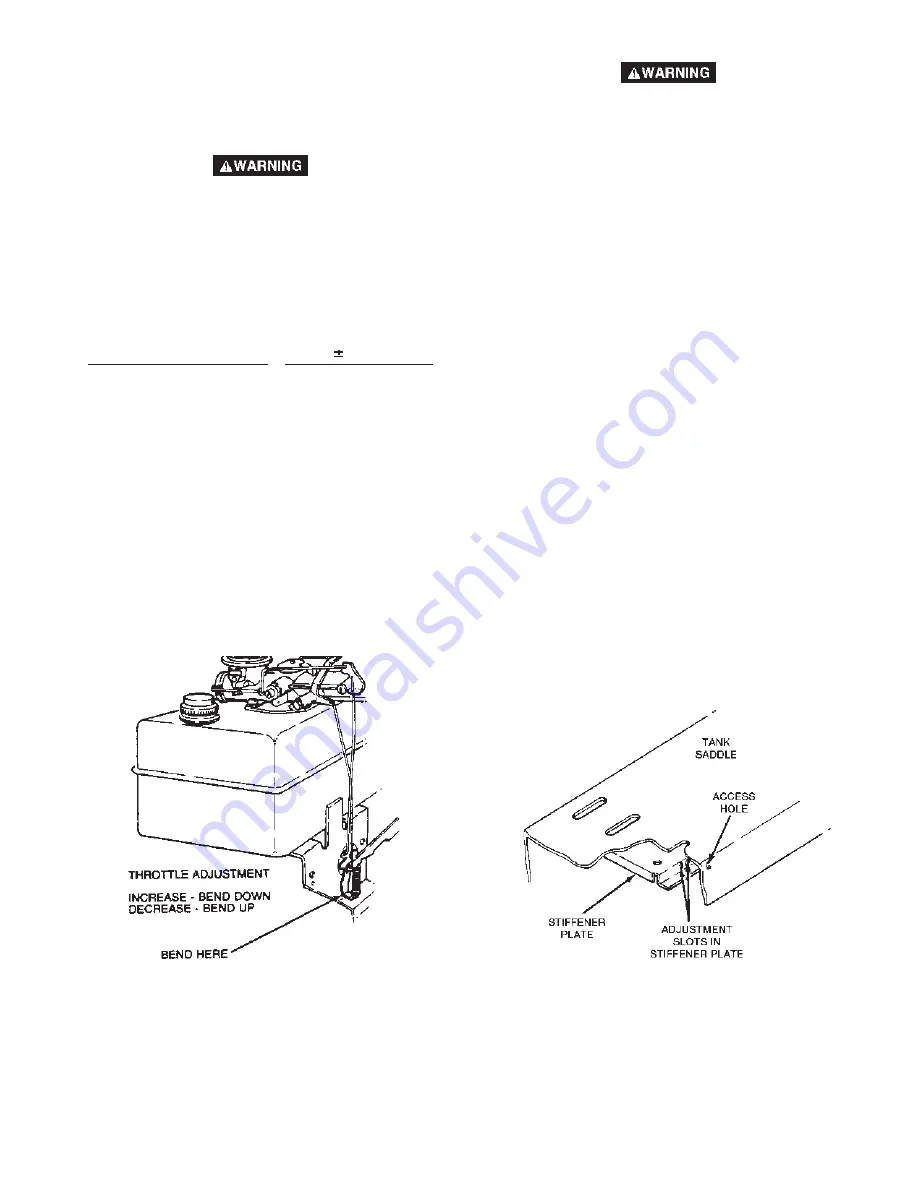

Loosen four engine mounting screws, two saddle/

stiffener plate screws, handle set screw, and stiff

ener bar nut on engine and slide engine toward

compressor.

4.

Remove belt and replace with new.

NOTE

The belt must be centered over the grooves

on the flywheel and engine pulley.

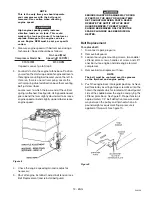

5.

Push the engine back into regular position. Achieve

belt tension by inserting a large screwdriver into the

hole in the saddle which is located on the belt guard

side of the saddle below the engine and prying the

stiffener plate back. See figure 9. Proper tension is

approximately 1/4" belt deflection measured mid

way between the pulley and flywheel when a 3-

pound weight or equivalent finger pressure is

applied at this point. See figure 10.

Figure 9