12 - ENG

D20396

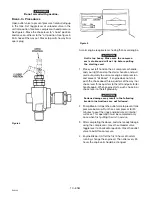

1. Release air pressure from the air tank.

2. Loosen the top and bottom tube nuts and remove the

outlet tube (Nos. 4 and 6).

3. Unscrew the check valve (turn counterclockwise)

using a socket wrench (No. 3).

4. Check that the valve disc moves freely inside the

check valve and that the spring holds the disc in the

upper, closed position. The check valve may be

cleaned with a solvent.

5. Apply sealant to the check valve threads. Reinstall

the check valve (turn clockwise). The disc should still

move freely — do not overtighten.

6. Replace the outlet tube and tighten top and bottom

nuts (Nos. 6 and 4).

Safety Valve — Inspection and Replace-

ment

IF THE SAFETY VALVE DOES NOT WORK

PROPERLY OVER-PRESSURIZATION MAY

OCCUR, CAUSING AIR TANK RUPTURE OR

EXPLOSION. OCCASIONALLY PULL THE

RING ON THE SAFETY VALVE TO MAKE

SURE THAT THE SAFETY VALVE OPERATES

FREELY. IF THE VALVE IS STUCK OR DOES

NOT OPERATE SMOOTHLY, IT MUST BE

REPLACED WITH THE SAME TYPE OF VALVE

HAVING AN IDENTICAL PRESSURE RATING.

Engine — Oil Change and Air Cleaner

See Briggs & Stratton "Operating and Maintenance In-

structions" for information regarding engine oil changes

and air cleaner service.

Engine — Adjustments

Read the Briggs & Stratton "Operating and Maintenance

Instructions" that were provided with your compressor.

The gasoline engine was adjusted and set at the factory

to ensure correct operation. However, variations in gaso-

line quality and octane, humidity, altitude or load may

adversely affect engine performance. As a result, minor

adjustments of fuel mixture or speed controls may be

necessary.

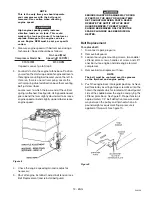

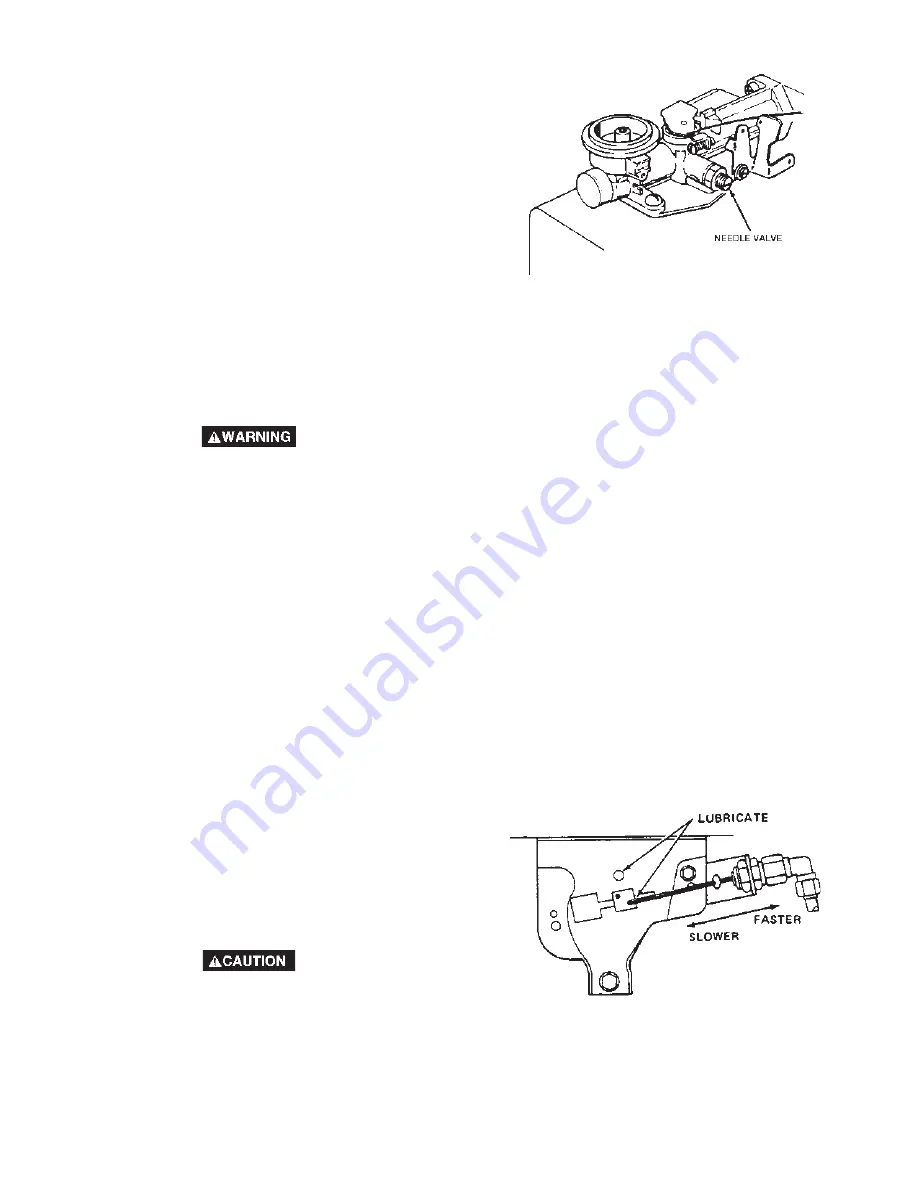

To adjust the fuel mixture, turn the needle valve clock-

wise until it closes. See figure 6.

The needle valve point may be damaged if

turned in too far.

Turn the needle valve 1½ revolutions counterclockwise

to establish a point of reference. Start the engine and

allow it to warm up.

Figure 6

NOTE

The air cleaner must be in place when any

carburetor adjustments are made.

Turn the needle valve clockwise (in) until the

engine misses, noting the valve position

(lean mixture). Turn the needle valve coun-

terclockwise (out) until engine runs roughly,

again noting valve position (rich mixture).

Now, turn the needle valve clockwise (in) to

the point midway between lean and rich

where the engine runs smoothly.

If the compressor stalls frequently during

acceleration from idle speed, richen mixture

sightly (by turning the needle valve out

slowly). If this adjustment does not elimi-

nate the stalls, adjust the idle speed to a

slightly higher level by loosening the two jam

nuts on the throttle control cylinder, read-

justing its position and retightening the

nuts. See figure 7. Proper idle speed is

between 2400 and 2600 RPM.

If the throttle mechanism fails to operate

smoothly, preventing the engine from returing

to full throttle speed when tank pressure

falls below 90 psig, it may be necessary to

lubricate it with a light lubricating oil. See

figure 7.

Proper no-load engine speed may be checked and

adjusted using the following procedures:

1.

Remove the belt guard and belt. Start engine

Figure 7