35

Maintenance of the air filter

The air filter must be cleaned intermediately or be re-

placed by a new one (refer to the instructions on inter-

mediate cleaning).

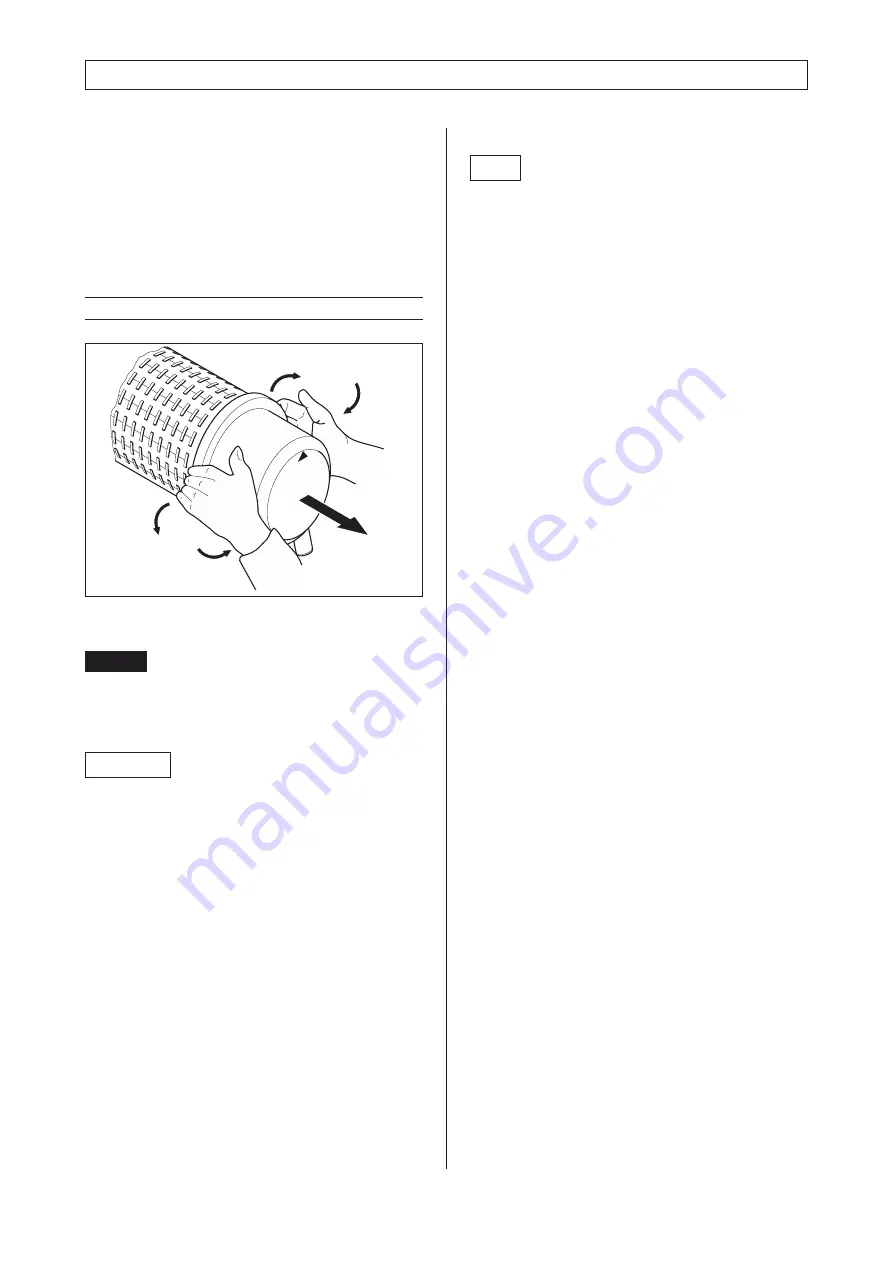

Intermediate cleaning of the air filter

Note

Intermediate cleaning can be done no more than five

times.

The air filter must be replaced when damaged, after

five intermediate cleaning procedures or after two

years at the latest.

Clean the filter carefully in order to avoid damage to

the filter material and ensure that no dust enters the

clean air side of the filter.

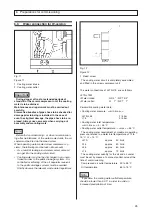

Intermediate cleaning is to be carried out as follows :

• Pull both spring latches at the lower part of the hou-

sing outwards and remove the lower part

• Remove the cover from the dust collector (lower part

of the housing) and empty it.

• The collector must not be more than half full - if re-

quired, shorten the maintenance intervals.

• Carry out an intermediate cleaning of the air filter

cartridge (observe the note on "intermediate cle-

aning") or replace it by a new one.

• Carefully slide the air filter cartridge into the housing.

When closing the housing, the air filter cartridge is

automatically placed in the correct position.

• Fit the cover into the dust collector (lower part of the

housing).

Attention: Take note of the marking for the correct

position.

• Close the air filter with the lower part of the housing.

The spring latches must snap into place.

Changing intervals of oil fine separators

The operating conditions (e.g. coolant temperatures),

the operating modes and the quality of the intake air

(e.g. content of dust, content of gaseous foreign matter

such as SO

2

, solvent vapours, etc.) have a strong influ-

ence on the oil change intervals. For such applications,

the required changing intervals could be shorter.

8.7

Air filter change/check

Fig. 24

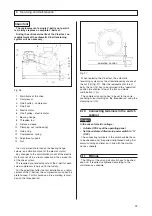

Danger

.

Only perform checks and carry out work on the

screw compressor when the unit is out of operation

and depressurized !

Important

Never operate the screw compressor unit without

air filter (even a short operating time without this fil-

ter can result in considerable damage to the machi-

ne) !

A clogged air filter must be cleaned or replaced when

the maintenance point has been reached.

If the air filter cartridge is monitored (option), a high

differential pressure is indicated on the operating pa-

nel. When the corresponding LED lights up, the air filter

cartridge is to be replaced.

Check the air filter for accumulated dust at least once

a week or, if required, daily.

During maintenance work, take care that no dirt en-

ters the clean air side of the air filter.

pull

push

8. Servicing and maintenance