36

8. Servicing and maintenance

Intermediate cleaning of the air filter by

blowing through with compressed air

Danger

.

When blowing through an air filter, observe the follo-

wing :

• Wear protective goggles and a breathing mask

• The pressure of the compressed air must not ex-

ceed 5 bar

• Blow through the air filter from the inside to the

outside until the formation of dust has considerab-

ly decreased.

Danger

.

Never use gasoline, alkaline solutions or hot liquids

for cleaning !

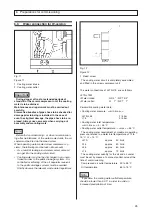

Rinse the filter as follows :

• Swirl the air filter cartridge in luke-warm water which

contains a special non-foaming rinsing agent

• Let the air filter dry

• Never install wet or damp air filters.

Check the air filter for damage

Before reinstalling the cleaned air filter, it must be tho-

roughly checked for cracks, holes or other damage by

examining it against the light using a bright light source

(portable lamp). Check also the seals.

Changing intervals for filter and

separator cartridges

The operating conditions (e.g. coolant temperatures),

the operating modes and the quality of the intake air

(e.g. content of dust, content of gaseous foreign matter

such as SO

2

, solvent vapours, etc.) have a strong influ-

ence on the service life of the filters (air filters, oil filters,

fine separators). For such applications, the required

changing intervals could be shorter.

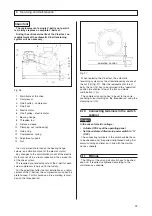

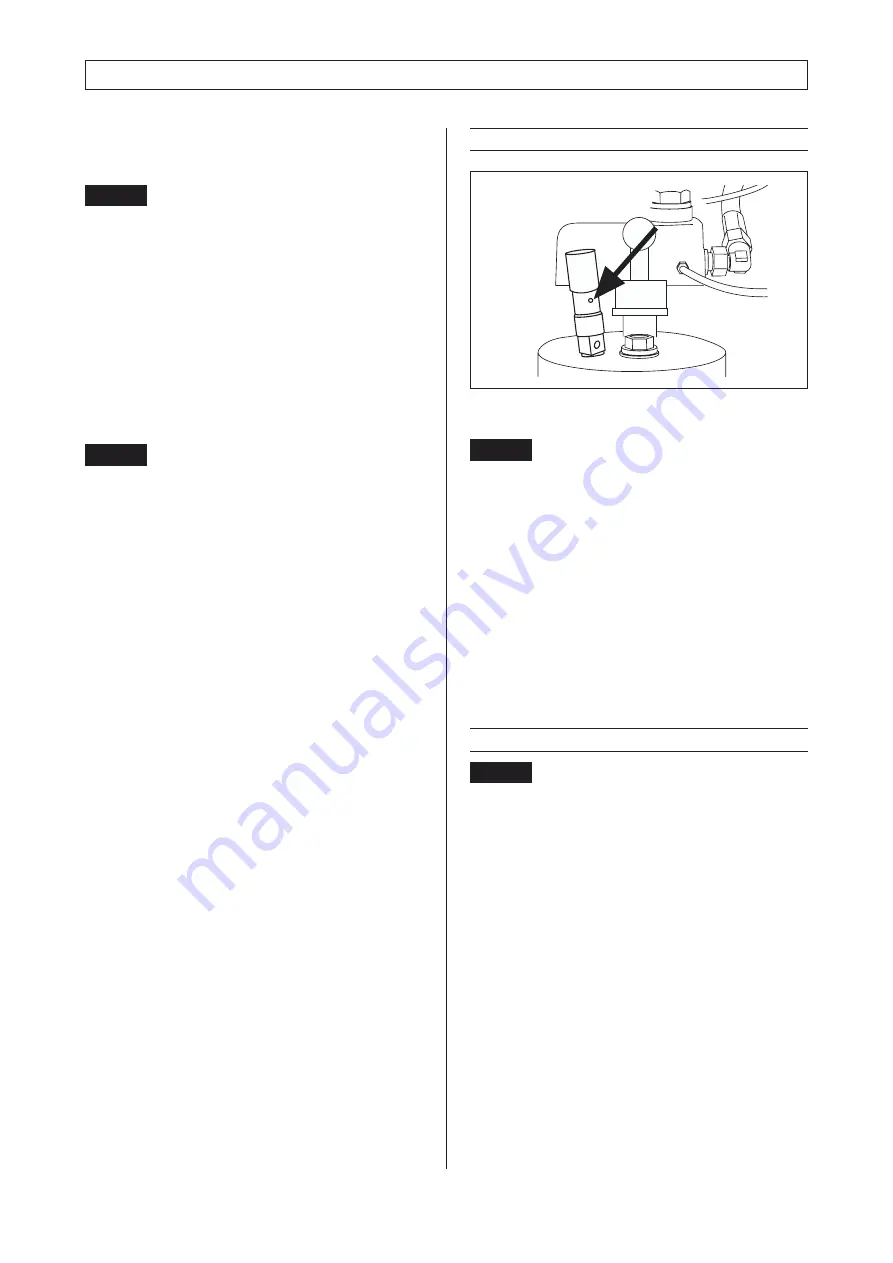

8.8

Safety valve

Intermediate cleaning of the air filter by

rinsing

Fig. 25

Danger

.

Never operate a screw compressor unit with a de-

fective safety valve !

Before each commissioning, check the safety val-

ve for function by turning the knurled cap at the safe-

ty valve at operating pressure.

If the safety valve does not function properly, it

must be immediately replaced by a new safety valve

with the corresponding pressure rating.

The safety valve can be hot as a result of previous

operation !

Escaping air can be hot and contain oil (danger of

burning/scalding) !

Danger

.

Only perform checks and carry out work when the

screw compressor unit is out of operation and de-

pressurized !

Any safety equipment which had to be removed for

the replacement of the V-belt set must be remounted

after completion of this work.

8.9

V-belts - automatic tensioning system