Page 5

STEAM PIPING INSTALLATION INSTRUCTIONS

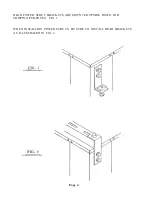

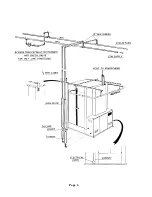

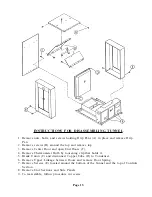

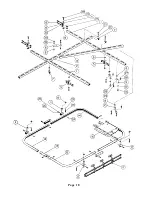

Refer to illustration on next page

IMPORTANT: INSTALL STEAM PIPING IN ACCORDANCE WITH

ALL LOCAL REGULATIONS AND REQUIREMENTS

1. Set and anchor Tunnel in position. Machine should be level to assure proper steam

circulation.

2. To prevent condensate draining from headers to Tunnel, piping should have a

minimum riser 12 above each respective header as illustrated. Do not make steam

connection to header with a horizontal or downwardly facing tee or elbow.

3. Whenever possible, horizontal runs of steam lines must drain, by gravity, to

respective steam header. Water pockets, or an improperly drained steam header

will provide wetsteam, causing improper operation of Tunnel. If pockets or

improper drainage cannot beeliminated, install a by-pass trap to drain condensate

from the low point in the steam supply header to the return.

4. In both the steam supply and steam return line, it is recommended that each have a

1/2 union and 1/2 globe valve. This will enable you to disconnect the steam

connections and service the Tunnel while your plant is in operation.

5. When Tunnel is on the end of a line of equipment extend headers at least 4 ft.

beyond Tunnel. Install globe valve, union, check valve and by-pass trap at end of

line. If gravity return to boiler, omit trap.

6. Insulate steam supply and return line for safety of operator and safety while

servicing Tunnel.

7. Keep Tunnel in good working condition. Repair or replace any worn or defective

parts.

8. If steam is dirty, it may be advisable to install a filter or blow-down ahead of tunnel.

Maintenance

The interior of the tunnel will turn white as the protective zinc oxide coating forms.

Do not try to remove this coating.

Do remove lint, dust, and boiler compound or red rust which is entrained by the steam.

Touch-up scratches and chips in the paint.

A good car wax will extend life of the painted surface.

Содержание FINTUNMAN67

Страница 3: ...Page 3...

Страница 6: ...Page 6...

Страница 18: ...Page 18...

Страница 22: ...Page 22...

Страница 28: ...Page 28...

Страница 30: ...Page 30...

Страница 32: ...Page 32...

Страница 34: ...Page 34...

Страница 39: ...Page 39...

Страница 40: ...Page 40...

Страница 41: ...Page 41...