5. Rear main bearing cap and bolts to the block.

• On 7.4L engines, apply anaerobic sealing com

pound to the rear bearing cap sealing face or to

the rear bearing cap channel of the engine

block, from the corner of the rear thrust bearing

pocket to the edge of the channel as shown in

figure

68

. Do not allow any sealant on either

crankshaft or rear oil seal.

Q ,

Tighten

• Rear main bearing cap bolts temporarily to 4

N-m (35 lbs. in.).

t } |

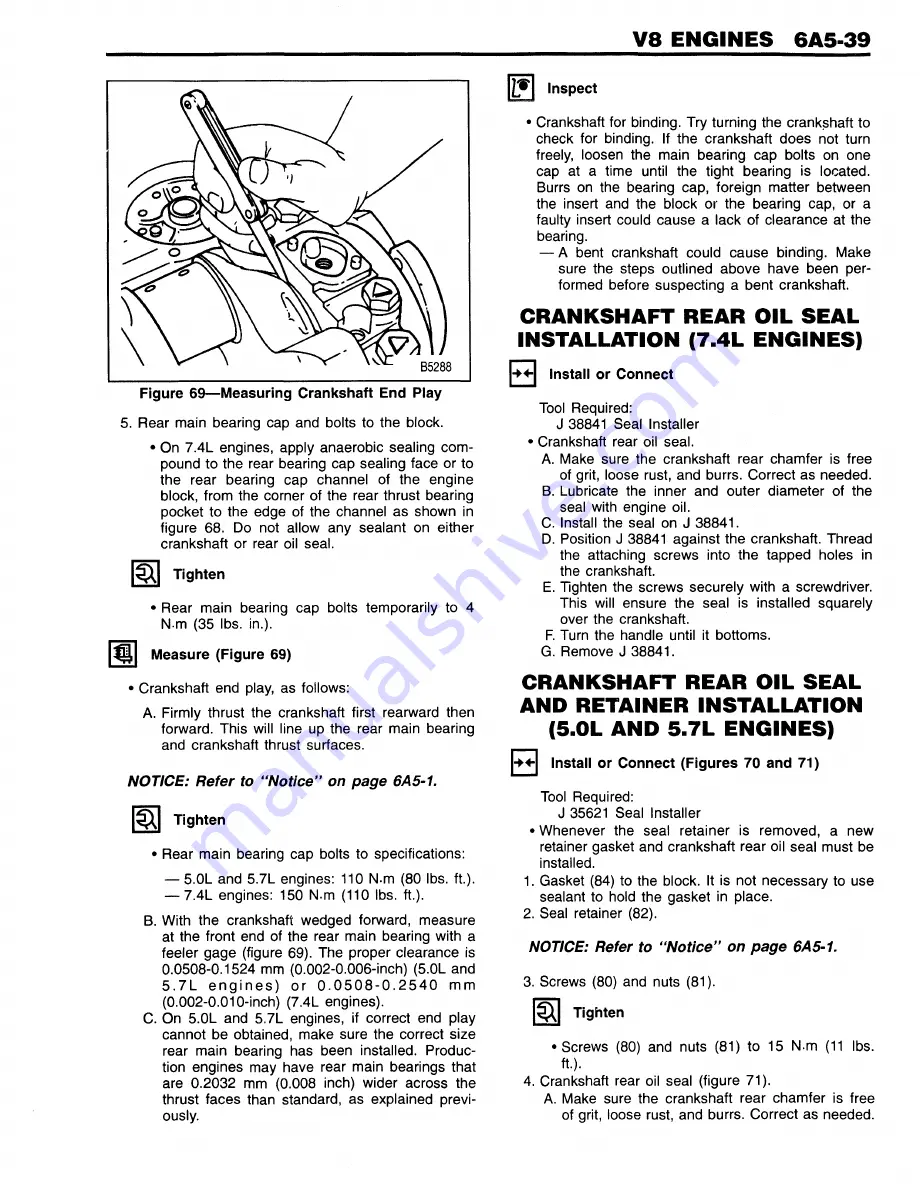

Measure (Figure 69)

Crankshaft end play, as follows:

A. Firmly thrust the crankshaft first rearward then

forward. This will line up the rear main bearing

and crankshaft thrust surfaces.

N O T IC E : R e f e r to “ N o t i c e ” o n p a g e 6 A 5 -1 .

Tighten

• Rear main bearing cap bolts to specifications:

— 5.0L and 5.7L engines: 110 N-m (80 lbs. ft.).

— 7.4L engines: 150 N-m (110 lbs. ft.).

B. With the crankshaft wedged forward, measure

at the front end of the rear main bearing with a

feeler gage (figure 69). The proper clearance is

0.0508-0.1524 mm (0.002-0.006-inch) (5.0L and

5 .7 L e n g in e s ) o r 0 . 0 5 0 8 - 0 . 2 5 4 0 m m

(0.002-0.010-inch) (7.4L engines).

C. On 5.0L and 5.7L engines, if correct end play

cannot be obtained, make sure the correct size

rear main bearing has been installed. Produc

tion engines may have rear main bearings that

are 0.2032 mm (0.008 inch) wider across the

thrust faces than standard, as explained previ

ously.

P

Inspect

• Crankshaft for binding. Try turning the crankshaft to

check for binding. If the crankshaft does not turn

freely, loosen the main bearing cap bolts on one

cap at a time until the tight bearing is located.

Burrs on the bearing cap, foreign matter between

the insert and the block or the bearing cap, or a

faulty insert could cause a lack of clearance at the

bearing.

— A bent crankshaft could cause binding. Make

sure the steps outlined above have been per

formed before suspecting a bent crankshaft.

CRANKSHAFT REAR O IL SEAL

INSTALLATION (7.4L ENGINES)

-►<-

Install or Connect

Tool Required:

J 38841 Seal Installer

• Crankshaft rear oil seal.

A. Make sure the crankshaft rear chamfer is free

of grit, loose rust, and burrs. Correct as needed.

B. Lubricate the inner and outer diameter of the

seal with engine oil.

C. Install the seal on J 38841.

D. Position J 38841 against the crankshaft. Thread

the attaching screws into the tapped holes in

the crankshaft.

E. Tighten the screws securely with a screwdriver.

This will ensure the seal is installed squarely

over the crankshaft.

F. Turn the handle until it bottoms.

G. Remove J 38841.

CRANKSHAFT REAR O IL SEAL

AND RETAINER INSTALLATION

(5.0L AND 5.7L ENGINES)

■¥+

Install or Connect (Figures 70 and 71)

Tool Required:

J 35621 Seal Installer

• Whenever the seal retainer is removed, a new

retainer gasket and crankshaft rear oil seal must be

installed.

1

. Gasket (84) to the block. It is not necessary to use

sealant to hold the gasket in place.

2. Seal retainer (82).

N O T IC E : R e f e r to “N o t i c e ” o n p a g e 6 A 5 -1 .

3. Screws (80) and nuts (81).

Tighten

•S crew s (80) and nuts (81) to 15 N-m (11 lbs.

ft.).

4. Crankshaft rear oil seal (figure 71).

A. Make sure the crankshaft rear chamfer is free

of grit, loose rust, and burrs. Correct as needed.

Содержание Light Duty Truck 1994 Series

Страница 1: ......

Страница 11: ...VIEW A p n n n j VIEW C F7554 Figure 10 Hydra Matic 4L60 E Transmission I D Location ...

Страница 15: ...G VAN MODELS Rally Sportvan Cutaway Van Extended Van Vandura Chevy Van Magnavan Hi Cube Van F7569 ...

Страница 17: ...S T PICKUP REGULAR CAB 2 DOOR S T UTILITY VEHICLE S T PICKUP EXTENDED CAB 4 DOOR S T UTILITY VEHICLE 2900r4506 ...

Страница 24: ...NOTES ...

Страница 26: ... ...

Страница 69: ...NOTES ...

Страница 71: ...3 2 STEERING ...

Страница 73: ......

Страница 84: ......

Страница 102: ...40 ...

Страница 130: ...NOTES ...

Страница 146: ...NOTES ...

Страница 162: ...NOTES ...

Страница 166: ...Figure 5 Removing the Pinion Flange Figure 6 Pressing the Drive Pinion from the Cage ...

Страница 178: ...Figure 3 Spreading the Differential Case Figure 4 Removing the Differential ...

Страница 190: ...NOTES ...

Страница 202: ...NOTES ...

Страница 206: ...F5785 ...

Страница 209: ...Figure 11 Remove the Pinion Flange F4696 F4759 Figure 14 Removing the Differential Side Bearing ...

Страница 212: ...B Button Moved Out of Bearing Bore F5791 ...

Страница 228: ...NOTES ...

Страница 232: ......

Страница 234: ......

Страница 236: ...Adjuster 63 Bolt 64 Lock Figure 10 Turning the Adjuster Plug K3 Models ...

Страница 237: ...Figure 13 Removing the Pinion Seal 39 Bearing Cup Figure 16 Removing the Inner Bearing Cap ...

Страница 247: ...C Measure with Axle Shaft Forced Outboard 1 Shaft 5 Tube 9 Carrier Connector 23 Output Shaft 29 Carrier Case F5877 ...

Страница 261: ...F7475 ...

Страница 267: ...B Button Moved Out of Bearing Bore F5791 ...

Страница 294: ...NOTES ...

Страница 300: ...NOTES ...

Страница 318: ...NOTES ...

Страница 322: ...SR207LN2 EDS ...

Страница 324: ......

Страница 326: ...OVERHEAD OILING AND RETURN MAIN OIL GALLERY N30005 6A2 J EDS ...

Страница 368: ...103 153 127 V1200 ...

Страница 370: ......

Страница 372: ......

Страница 374: ...F9375 Figure 7 Engine Lubrication Diagram Engines Without Balance Shaft ...

Страница 375: ...Front View Rear View Showing Path Of Oil To Timing Chain Showing Main Gallery Oil Filter And Crankshaft Oil Feed V0575 ...

Страница 376: ...Figure 9 Engine Lubrication Diagram Engines With Balance Shaft ...

Страница 399: ...V2974 ...

Страница 410: ......

Страница 412: ...195 196 201 174 252 163 165 164 244 3706r3924 ...

Страница 452: ......

Страница 454: ...163 164 V1202 ...

Страница 456: ...20 21x 302 210 4 0 41 2 5 2 5 1 2 51 4 2 e3 54 3 9 252 252 S 255 255 25 6 256 209 V1196 ...

Страница 458: ...100 1 8 4 185 183 177 v 75 201 3706r1204 ...

Страница 460: ......

Страница 510: ......

Страница 512: ...V2131 ...

Страница 514: ...110 106 106 103 90 93 89 88 87 86 v 7 7 7 7 j A _ 111 f t 2 a a s 53 49 L 47 46 3706r4751 ...

Страница 516: ...259 260 150 237 S lM 180 167180 J 1 82 183 170 169 1 1 78 1 7 9 213212 2 0 7 205 r i 3706r4752 ...

Страница 566: ...NOTES ...

Страница 574: ...NOTES ...

Страница 618: ...SPECIAL TOOLS ...

Страница 620: ...NOTES ...

Страница 672: ......

Страница 682: ......

Страница 686: ......

Страница 689: ...SPRINGS LOCATED IN THE PUMP PRESSURE CONV CL REGULATOR VALVE SPRINGS LOCATED IN THE VALVE BODY 3 4 SHIFT ...

Страница 694: ...RH0213 4L60 E ...

Страница 695: ...657 659 m i J 8092 H J 34196 4 3 34196 5 657 658 665 J 23907 J 7004 1 J 8092 RH0214 4L60 E ...

Страница 696: ...J 8092 J 34196 4 33 31 J 8092 RH0215 4L60 E ...

Страница 697: ...SPECIAL TOOLS ...

Страница 698: ...SPECIAL TOOLS ...

Страница 758: ...RH0194 4L80 E ...

Страница 764: ......

Страница 770: ...SPECIAL TOOLS ...

Страница 771: ...SPECIAL TOOLS CONT ...

Страница 772: ......

Страница 775: ......

Страница 776: ......

Страница 785: ......

Страница 804: ...NOTES ...

Страница 806: ......

Страница 808: ......

Страница 822: ...3707r5079 ...

Страница 840: ......

Страница 848: ...NOTES ...

Страница 852: ......

Страница 859: ...17 Rear Case Half 18 Oil Pump Pick Up Tube 26 Connector Dowel Pin Location Pump Pick Up Screen F5434 ...

Страница 860: ...F5435 ...

Страница 866: ......

Страница 878: ...F9167 ...

Страница 882: ...16 FrontOutputShaft 18 DrivtQNr 19 DrivenGm t 20 DriveChain 22 FrontOutputBearing V2836 ...

Страница 890: ...F9168 ...

Страница 908: ......

Страница 914: ...J 2619 01 46 Rear Case 85 Front Output Shaft Rear Bearing F7659 Figure 21 Removing the Front Output Shaft Rear Bearing ...

Страница 919: ......