4

ENGLISH

01

06

03

02

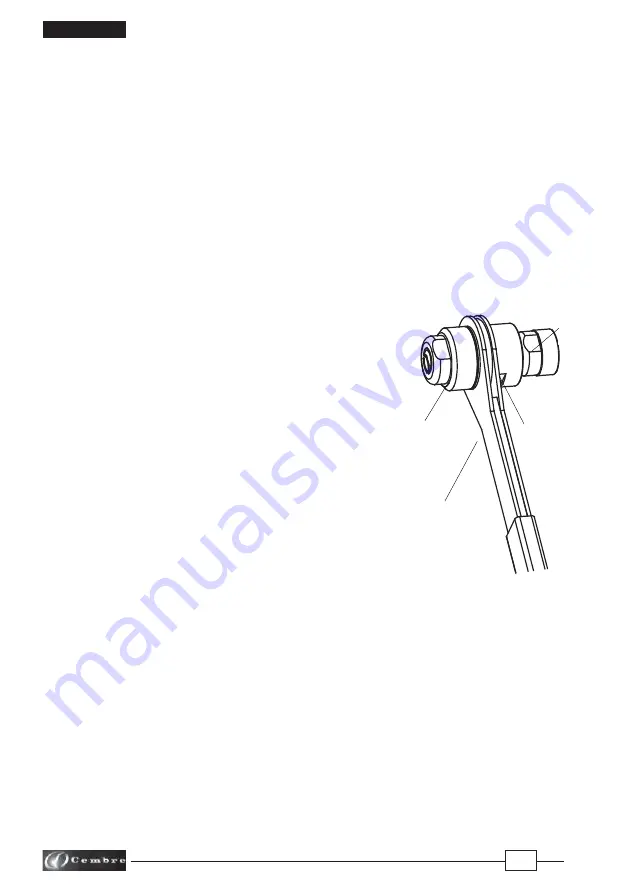

FIG. 2

3. INSTRUCTIONS FOR USE

3.1) Setting

(Ref. to Figs. 2 - 7)

– Drill rail web or,

if already drilled, use a suitable tool to clean the hole

(Fig. 3).

– Check the size of the hole with the "GO/NO GO" gauge

CAL ....

;

the hole size is correct

only if the

green part enters the hole

. If the red part enters, the hole is too large (Fig. 4).

– Insert the

AR...-1

copper bush into the rail hole (Fig. 5).

– Turn, anti-clockwise, the support (06) up to the automatic stop (Fig. 2).

In order to achieve the maximum possible stroke length, the support (06) must be completely

turned (anti-clockwise) up to the mechanical stop.

– Insert the calibrated plunger

OG 6.5

into the bush, on the fl ange side ( Fig. 6).

– Using the recess in the gauge

CAL ....

screw and tighten the plunger

OG 6.5

into the tool (Fig. 7).

3.2) Extrusion

(Ref. to Figs. 2; 8; 9)

Before proceeding to the extrusion process, make sure

that the calibrated plunger is fully screwed in the tool

housing.

– Operate the tool, to pull the plunger

OG 6.5

through

the bush and extrude the bush onto the sides of the

hole (Fig. 8), the bush will also extrude itself around the

opposite side of the rail web (Fig. 9).

Should the calibrated plunger not fully exit from the

bush and the tool remain blocked, please proceed as

follows:

– Unscrew and remove the adjustment locking ring (02).

– Remove, reverse and refi t the ratchet handle (01).

– Manually grip the support (06) and rotate the ratchet

handle (01) anti-clockwise, up to the automatic stop.

– Turn the support (06) in a clockwise direction up to the automatic stop.

– Turn the nut (03) in a clockwise direction until the support (06) butts fi rmly against the rail web.

– Remove, reverse and refi t the ratchet handle (01) back to the original position.

– Refi t and tighten the adjustment locking ring (02).

Rotate the ratchet handle (01) in a clockwise direction to complete the installation of the contact

bush.