26

Gain can be applied in order to make the image brighter. However, large gain values will

increase the noise in the images. Gain is typically applied if the original image is too dark.

This can be the case with very dark or highly reflective metal surfaces.

Gamma is a nonlinear correction tool that can increase the visibility of dark regions with

respect to the brighter regions. Gamma correction can often improve the visual appearance of

the image.

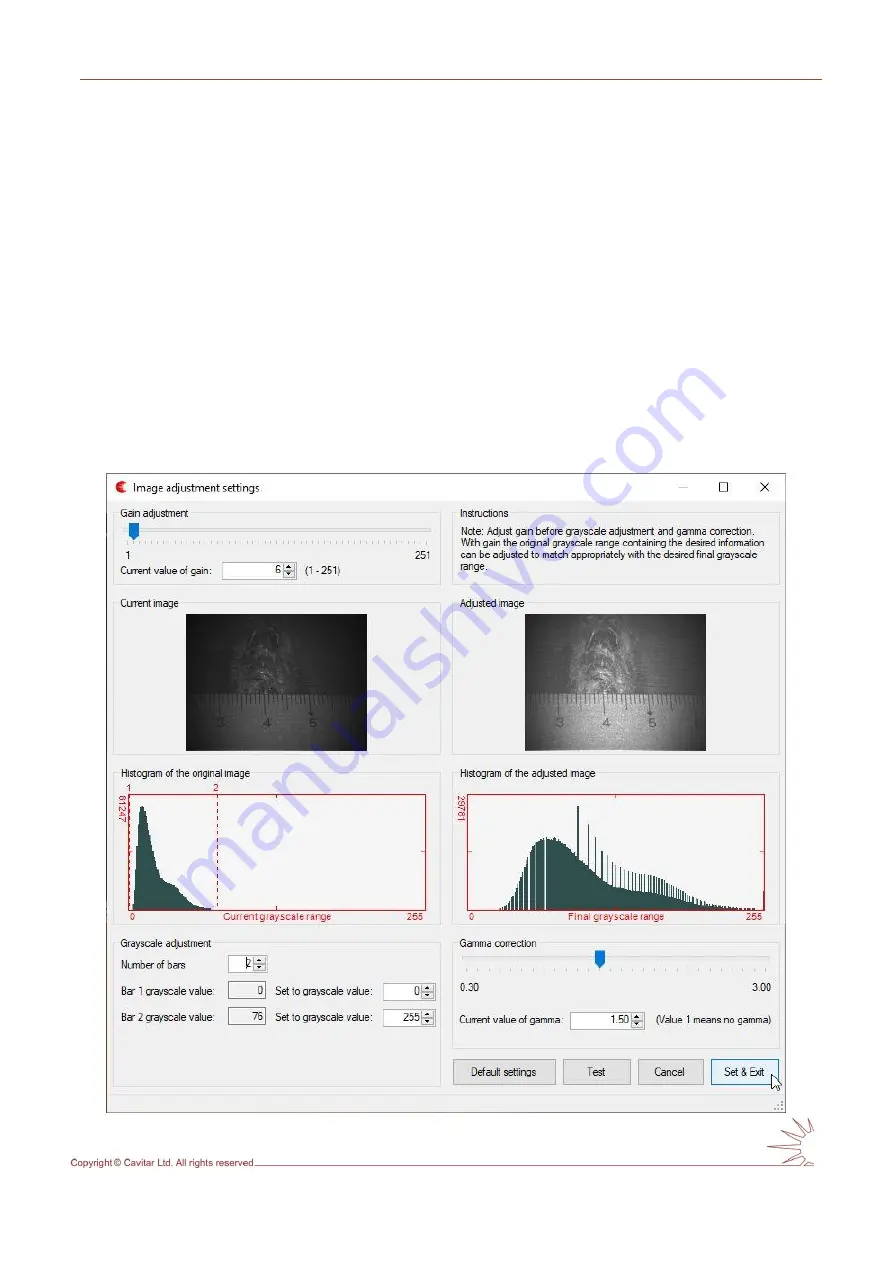

Grayscale adjustment can be used for selecting desired ranges of grayscale values that will be

displayed on the screen as different ranges of grayscale values. This can have a big effect on

the appearance of the image. As an example, one can assign a larger range for the interesting

grayscale values and a smaller range for the less interesting grayscale values. The desired

ranges can be set by moving the vertical red bars below the left-hand image (“Current

image”). This is shown in Fig. 5.14, where bar 2 has been moved leftwards in such a way that

original grayscale range 0…76 will be scaled to new grayscale range 0…255. After pressing

“Test” button the effect can be seen in the “Adjusted image” and “Histogram of the adjusted

image”.

Fig. 5.14. Desired grayscale ranges selected.

Содержание C300

Страница 1: ...CAVITAR Welding Camera C300 Operating Manual ...

Страница 14: ...12 Fig 4 2 close all other applications and click Next to start installation Fig 4 3 Click I Agree to continue ...

Страница 30: ...28 Fig 5 16 Guideline and grid properties ...

Страница 34: ...32 Fig 5 21 View after calibration ...