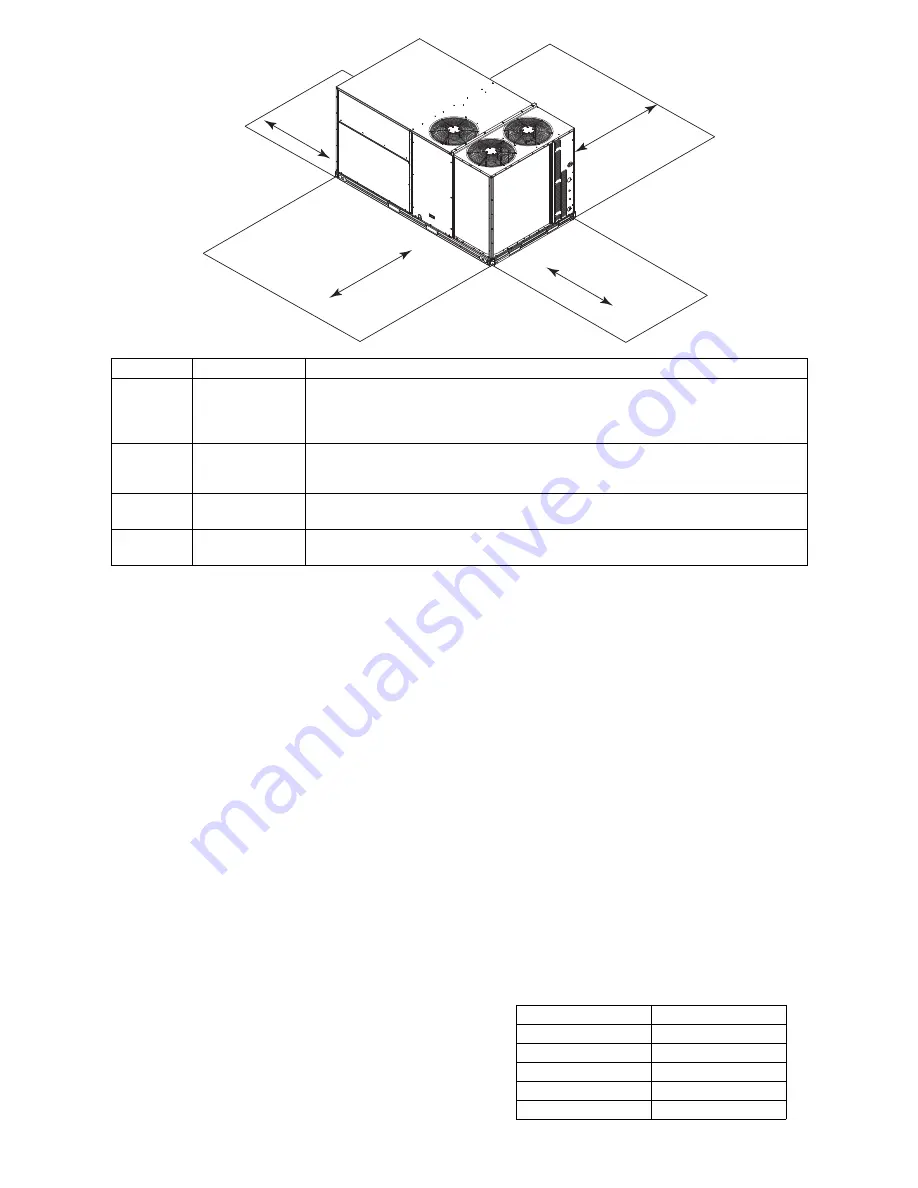

7

C

D

A

B

C09897B

LOCATION

DIMENSION

CONDITION

A

48---in (1219 mm)

18---in (457 mm)

18---in (457 mm)

12---in (305 mm)

Unit disconnect is mounted on panel

No disconnect, convenience outlet option

Recommended service clearance

Minimum clearance

B

42---in (1067 mm)

36---in (914 mm)

Special

Surface behind servicer is grounded (e.g., metal, masonry wall)

Surface behind servicer is electrically non---conductive (e.g., wood, fiberglass)

Check sources of flue products within 10---ft of unit fresh air intake hood

C

36---in (914 mm)

18---in (457 mm)

Side condensate drain is used

Minimum clearance

D

42---in (1067 mm)

36---in (914 mm)

Surface behind servicer is grounded (e.g., metal, masonry wall, another unit)

Surface behind servicer is electrically non---conductive (e.g., wood, fiberglass)

NOTE:

Unit not designed to have overhead obstruction. Contact Application Engineering for guidance on any application

planning overhead obstruction or for vertical clearances.

Fig. 3 -- Service Clearance Dimensional Drawing

REFRIGERATION SYSTEM

COMPONENTS

Each heat pump refrigeration system includes a

compressor, accumulator, reversing valve, dual--function

outdoor coil with vapor header check valve, cooling liquid

line with a filter drier and a check valve, dual--function

indoor coil with a vapor header check valve, and heating

liquid line with a check valve and a strainer. Size 14 units

have two compressor--circuits. See Fig. 4 for typical unit

piping schematic (4--row indoor coil with two

compressor--circuits is shown).

Dual--function outdoor and indoor coils are designed to

provide parallel coil circuits during evaporator--function

operation and converging coil circuits during the

condenser--function operation.

Reversing Valve and Check Valve Position

See Fig. 4 (on page 8) and Tables 1 -- 3.

Troubleshooting Refrigerant Pressure Problems and

Check Valves

Refer to Fig. 4 and the Cooling Mode and Heating Mode

tables (Tables 1 and 2).

Refrigerant System Pressure Access Ports

There are two access ports in each circuit -- on the suction

tube and the discharge tube near the compressor. These are

brass fittings with black plastic caps. The hose connection

fittings are standard

1

/

4

--inch SAE male flare couplings.

The brass fittings are two--piece High Flow valves, with a

receptacle base brazed to the tubing and an integral

spring--closed check valve core screwed into the base. See

Fig. 5 on page 8. This check valve is permanently

assembled into this core body and cannot be serviced

separately. Replace the entire core body if necessary. Service

tools are available from RCD that allow the replacement of

the check valve core without having to recover the entire

system refrigerant charge. Apply compressor refrigerant oil

to the check valve core’s bottom O--ring. Install the fitting

body and torque to 96

10 in--lbs (10.9

1 Nm). Do not

exceed 106 in--lbs (11.9 Nm) when tightening.

Table 1 – Cooling Mode (each circuit)

Component

Status/Position

Reversing Valve

Energized

Check Valve A

Closed

Check Valve B

Open

Check Valve C

Closed

Check Valve D

Open

Содержание 50TCQD

Страница 5: ...5 C14192 Fig 2 Unit Dimensional Drawing 14 Size Unit ...

Страница 6: ...6 C14193 Fig 2 Unit Dimensional Drawing 14 Size Unit cont ...

Страница 10: ...10 C10365 Fig 6 Roof Curb Details ...

Страница 17: ...17 a50 9707 Fig 26 Typical 50TCQ Control Wiring Diagram ...

Страница 18: ...18 a50 9708 Fig 27 Typical 50TCQ Power Wiring Diagram 208 230V 3 Phase 60Hz unit shown ...

Страница 43: ...43 a50 9710 Fig 50 PremierLinkt Controller Wiring Schematic ...

Страница 51: ...51 a50 9711 Fig 66 RTU Open Controller System Wiring Diagram ...