18

ENG

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

Par.

Description

Def.

Min.

Max.

UoM

Type Carel Modbus® R/W Note

Si

Unit of measure 1=°C/K/barg ¦ 2=°F/psig

1

1

2

-

I

16

143

R/W

IA

Enable operating mode modification 0/1 = yes/ no

0

0

1

-

I

15

142

R/W

U1

Enable manual valve positioning 0/1 = no/ yes

0

0

1

-

D

11

10

R/W

U2

Manual valve position

0

0

999

step

I

7

134

R/W

U3

Valve control steps: 1/2 = 480/960 steps

1

1

2

-

I

11

138

R/W

U4

Valve opening at start-up (evaporator/valve capacity ratio)

50

0

100

%

I

19

146

R/W

Fr

Firmware release

-

-

-

-

A

9

8

R

di

DI configuration: 1=start/stop regulation; 2=backup regulation

1

1

2

-

I

18

145

R/W

rt

Reserved

1

1

1

-

L1

S1 alarm: Minimum pressure

-1

-85(-121)

S1 alarm:

Max pressure

barg (psig)

A

20

19

R/W

H1

S1 alarm: Maximum pressure

-

S1 alarm:

Min press.

200 (392) barg (psig)

A

21

20

R/W

Tab. 7.a

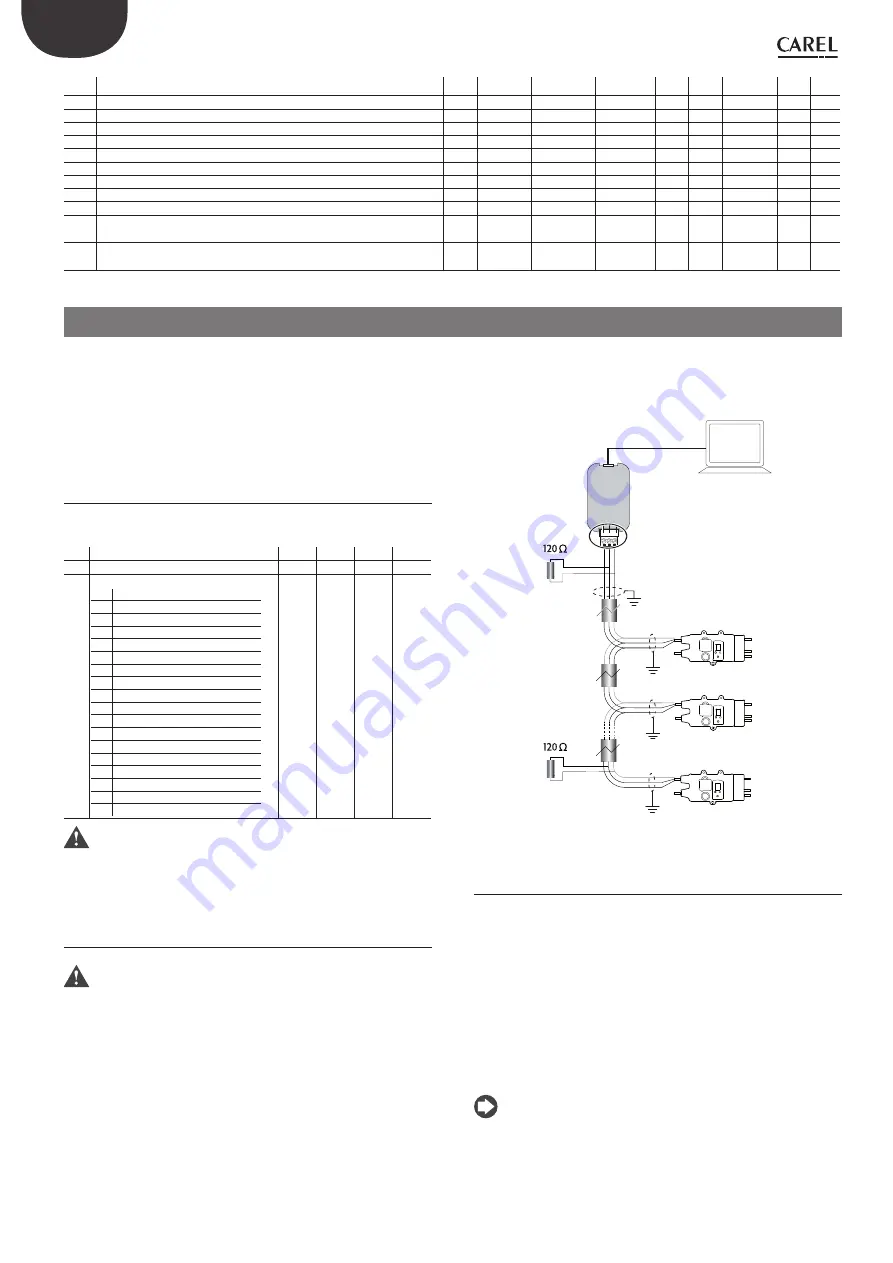

8. NETWORK CONNECTION

The driver can be connected via a network connection to:

1.

a computer running the VPM software, for setting the parameters

before commissioning;

2.

a pCO controller, loaded with the application program;

3.

a PlantVisor/PlantVisorPRO supervisor, for remote monitoring and

alarm detection.

8.1 RS485 serial configuration

n1 assigns to the controller an address for serial connection to a

supervisory and/or telemaintenance system.

Par. Description

Def.

Min.

Max. UoM

n1 Network address

1

1

99

-

n2 Baud rate (bit/s)

0 4800, 2 stop bit, parity none

1

9600, 2 stop bit, parity none

2

19200, 2 stop bit, parity none

3

4800, 1 stop bit, parity none

4

9600, 1 stop bit, parity none

5

19200, 1 stop bit, parity none

6

4800, 2 stop bit, parity even

7

9600, 2 stop bit, parity even

8

19200, 2 stop bit, parity even

9

4800, 1 stop bit, parity even

10 9600, 1 stop bit, parity even

11 19200, 1 stop bit, parity even

12 4800, 2 stop bit, parity odd

13 9600, 2 stop bit, parity odd

14 19200, 2 stop bit, parity odd

15 4800, 1 stop bit, parity odd

16 9600, 1 stop bit, parity odd

17 19200, 1 stop bit, parity odd

2

0

17

-

Important:

all controllers connected in a serial network need to be

set with the same communication parameters.

8.2 Network connection for commissioning

via PC

Warnings:

•

fasten the converter properly so as to prevent disconnection;

•

complete the wiring without power connected;

•

keep the CVSTDUMOR0 interface cables separate from the power

cables (power supply);

•

in compliance with standards on electromagnetic compatibility, a

shielded cable suitable for RS485 data transmission is used.

The RS485 converter is used to connect a computer running the VPM

software to the EVD ice driver via a serial network, for commissioning the

controllers. The system allows a maximum of 99 units, with a maximum

network length of 500 m. Connection requires the standard accessories

(RS485-USB converter, CAREL P/N CVSTDUMOR0) and a 120 Ω terminating

resistor to be installed on the terminals of the last connected controller.

Connect the RS485 converter to controllers and make the connections

as shown in the figure. To assign the serial address, see parameter n1. See

the converter technical leaflets for further information.

GND

USB-485

Converter

CVSTDUMOR0

USB

T+ T -

shield

shield

shield

shield

*

*

EVD ice 1

EVD ice 2

EVD ice ...n

VPM

Fig. 8.a

8.3 Visual parameter manager

Go to http://ksa.carel.com and follow the instructions below. Select in

sequence:

1.

“Software & Support”

2.

“Configuration & Updating Softwares”

3.

“Parametric Controller Software”

4.

“Visual Parametric Manager”

A window will open with the possibility to download two files:

1.

VPM_setup_X.Y.Z.W_full.zip: complete program;

2.

X.Y.Z.W_VPM_Devices_Upgrade.zip: upgrade for supported devices;

If this is the first installation, select Setup full, otherwise Upgrade. The

program installs automatically by running setup.exe.

Note:

if choosing complete installation (Setup full), uninstall any

previous versions of VPM.