14

ENG

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

PID parameters

Superheat control uses a PID algorithm. The control output is calculated

as the sum of separate contributions: proportional and integral.

•

the proportional action opens or closes the valve proportionally to

the variation in the superheat temperature. Thus the greater the K

(proportional gain)

the higher the response speed of the valve. The

proportional action does not consider the superheat set point, but

rather only reacts to variations. Therefore if the superheat value does

not vary significantly, the valve will essentially remain stationary and

the set point cannot be reached;

•

the integral action is linked to time and moves the valve in proportion

to the deviation of the superheat value from the set point. The greater

the deviations, the more intense the integral action; in addition, the

lower the value of Ti (

integral time)

, the more intense the action

will be. The integral time, in summary, represents the intensity of the

reaction of the valve, especially when the superheat value is not near

the set point.

See the “EEV system guide” +030220810 for further information on

calibrating PID control.

Par. Description

Def.

Min.

Max.

UoM

-

Superheat set point

11(20) LowSH: threshold 55 (99) K(°F)

CP PID proport. gain

15

0

800

-

ti

PID integral time

150

0

999

s

Note:

when selecting the type of Mode, the PID control values

suggested by CAREL will be automatically set for each application.

Protector control parameters

See the chapter “Protectors”.

5.2 Special control function: smooth lines

Note:

the Smooth_line parameter is only accessible via the

supervisor.

The smooth lines function optimises evaporator capacity based on actual

cooling demand, allowing more effective and stable control. The function

completely eliminates traditional on/off control cycles, modulating

the temperature exclusively using the electronic valve; superheat set

point is controlled through a precise PI control algorithm based on

the actual control temperature. The master controller (connected via

serial to EVD mini), through dynamic management of the Smooth_line

parameter, modifies the superheat set point for management of the

electronic expansion valve, from a minimum (SH_SET) to a maximum

( Smooth_line): this consequently acts directly on the PID

control algorithm that modifies the valve position. This is useful when

the control temperature approaches the set point; the Smooth_line

parameter is used to prevent the valve from closing, by reducing the

evaporator’s cooling capacity. In order to use this function, the digital

input must be configured as BACKUP. The Smooth_line parameter thus

allows the control set point to be adjusted instantly. In the event where

there is no network connection, the Smooth_line parameter is reset so as

to resume normal control (START/STOP from digital input and SH_SET as

the superheat set point). The main effects are:

•

no swings in temperature and superheat due to the set point being

reached;

•

stable temperature and superheat control;

•

maximum energy savings due to load stabilisation.

Par.

Description

Def.

Min.

Max. U.M.

di

DI configuration

1=start/stop

2=control backup

1

1

2

-

Smooth_line A: superheat set point

offset for smooth lines

0

-99(-55)

99(55) K/°F

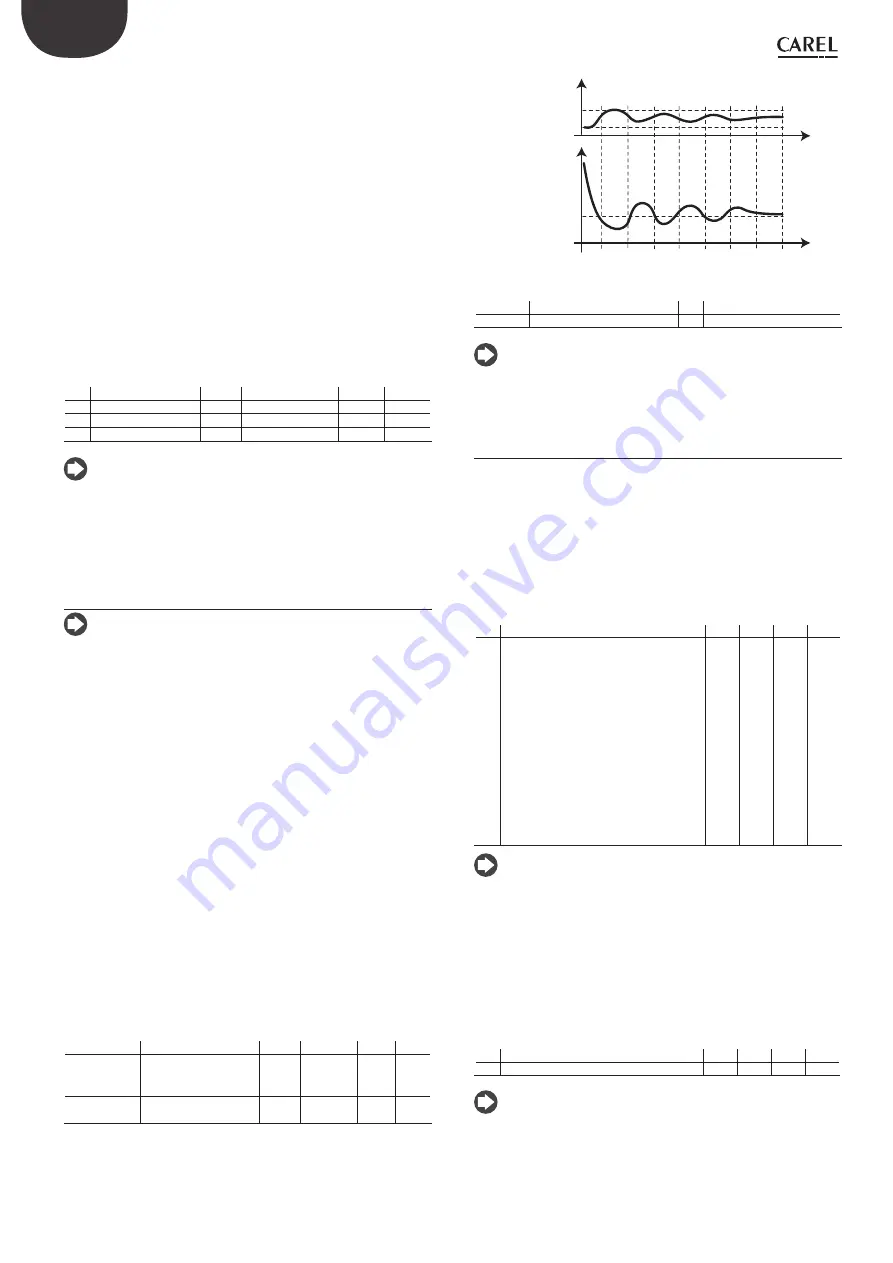

t

Temp. set

SH set

Smooth_line

t

Fig. 5.b

Key

SH set

Superheat set point

t

time

Temp.set Temperature set point

Note:

the temperature setting based on the corresponding set

point is managed by the master controller, while superheat control is

managed by the EVD ice.

5.3 Service parameters

The other configuration parameters, to be set where necessary before

starting the controller, concern :

•

the type of ratiometric pressure probe;

•

the serial address for network connection;

•

the type of unit of measure;

•

enabling change in type of control (Mode);

•

the number of steps (480/960) to control valve position.

Type of pressure probe (par. S1)

S1 is used to select the type of ratiometric pressure probe.

Par. Description

Def. Min. Max. UoM

S1

type of probe S1

1 = -1…4.2 barg

2 = 0.4…9.3 barg

3 = -1…9.3 barg

4 = 0…17.3 barg

5 = 0.85…34.2 barg

6 = 0…34.5 barg

7 = 0…45 barg

8 = -1…12.8 barg

9 = 0…20.7 barg

10 = 1.86…43.0 barg

11 = Reserved

12 = 0...60 barg

13 = 0...90 barg

3

1

13

-

Note:

when setting the probe type, the maximum and minimum

limits for the pressure alarm are automatically defined. See “Variables

aaccessible via serial connection”.

Network address (par. n1)

See the “Network connection” chapter.

Unit of measure (par. Si)

It is possible to select the measure system of the driver:

•

international (°C, K, barg);

•

imperial (°F, psig).

Par. Description

Def. Min. Max. UoM

Si

Unit of measure: 1=°C/K/barg; 2=°F/psig 1

1

2

-

Note:

the unit of measure K relates to degrees Kelvin adopted for

measuring the superheat and the related parameters.

When changing the unit of measure, all the values of the parameters

saved on the driver and all the measurements read by the probes will

be recalculated. This means that when changing the units of measure,

control remains unaltered.