179

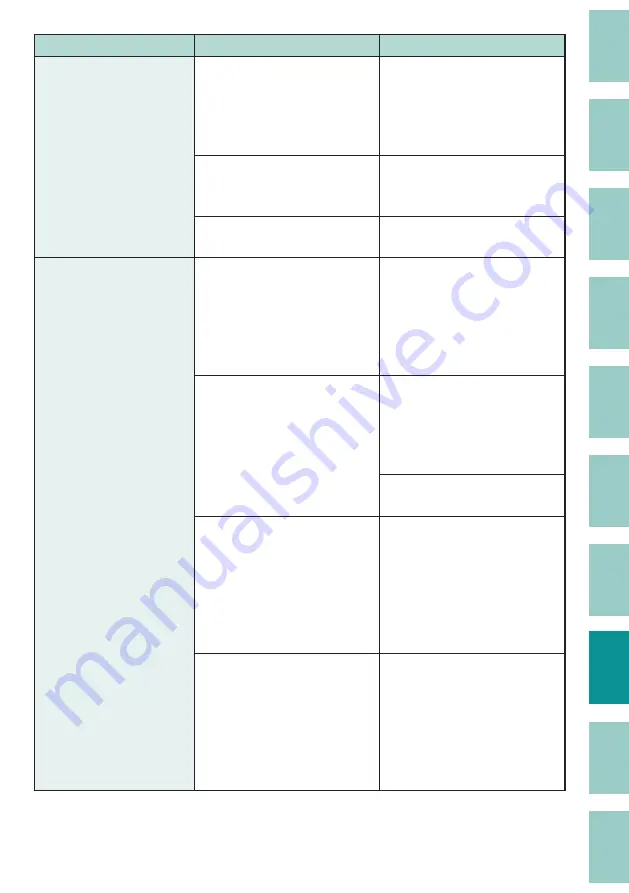

Problem

Cause/Things to Check

Solution

The device cannot make

full cuts.

The device cannot make

half cuts.

Half cuts are cut too

deep.

Are the cutter and blade

receiver set correctly?

for

information on how to set

the cutter and blade receiver

correctly.

Are the depth and motion of

the cut appropriate?

Please adjust the depth

of the cutter.

Is it time to replace the cutter?

Replace the cutter and blade

receiver.

The cutting position is

off .

The printed area gets cut.

The tube is cut at an

angle.

Are there any objects around

the media delivery port that

prevent the media from being

ejected?

Do not place any objects around

the media delivery port. If there

is an object blocking the outlet,

the tube or label tape may not

be ejected straight and may be

cut in a bent shape.

Is there any load on the tube

transport?

Place the printer and the print

media on the same table (or at

the same vertical position) so

that no load is applied to the

transport.

When using a tube reel, lighten

the load.

Is the tube twisted or warped?

Correct any twists or warps

before loading.

If the end of the tube is bent

due to winding or other

reasons, straighten it out or

cut off the bent portion before

loading it into the printer.

Depending on your print

media and environment, the

print position may be shifted or

the length of one tube (or one

label) may be diff erent from

the setting.

Make fi ne adjustments to the

print position and cut length.

If the problem is not corrected

by using the length adjust, set

the half cut to "Off " and cut

with scissors.