CHAPTER 6

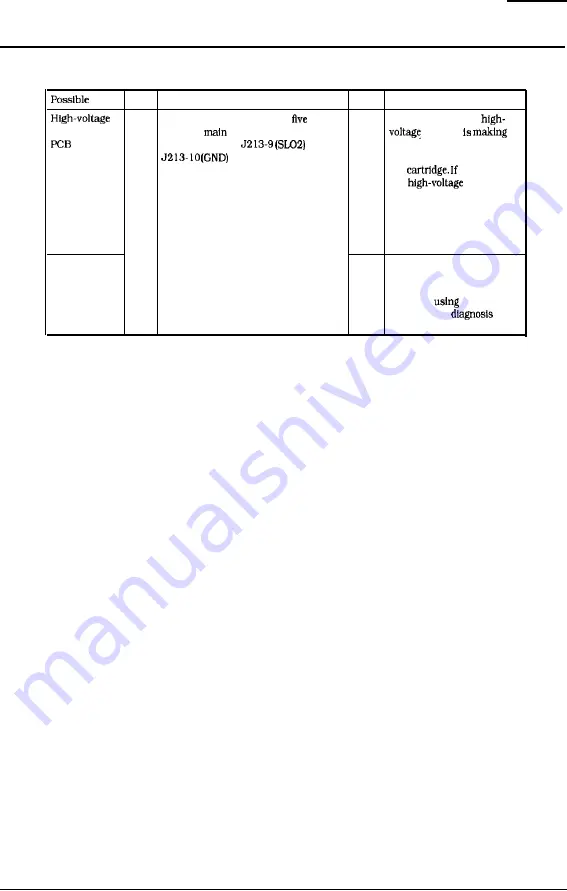

cause Step

Check

Result

Procedure

7

Perform a test print. About

seconds YES

Check whether the

power supply

after the

motor starts, does the

contact

voltage between

and

good contact with the

(Developing

on the DC controller

developing bias contact of

bias)

PCB become about 0.76 VDC?

the

It Is. replace

the

power

supply PCB. If the problem

persists after replacing the

PCB. check by using the

laser malfunction diagnosis

flowchart in Section III C.

DC controller

PCB

NO

Replace the DC controller

PCB. If the problem persists

after replacing the PCB,

check by

the laser

malfunction

flowchart in Section III C.

6-16

Содержание LBP-1260

Страница 1: ...LBP 1260 SERVICE MANUAL Canon...

Страница 35: ...l 29...

Страница 36: ...CNAPTER 1 1 30...

Страница 63: ...CHAPTER 2 This page intentionally left blank 2 26...

Страница 88: ......

Страница 139: ......

Страница 153: ...ER 6 This page intentionally left blank 6 7...

Страница 157: ...CHAPTER 6 o r J20 J215 I u IC201 El IC202 TB201 J214 J213 Fi m 6 7 6 11...

Страница 193: ...This page intentionally left blank 6 4 7...

Страница 194: ...CHAPTER 6 A Switches 1 I Figure 11 6 46...

Страница 196: ...B Sensore and Sotenoids Flgurc 6 12 6 50...

Страница 198: ...CHAPTER 6 C Motors and Others Figure 6 13 6 52...

Страница 200: ...CEtApTER 6 D PC Boards Figure 6 14 6 54...

Страница 202: ...E Connectors Figure 6 16 6 56...

Страница 203: ...Figure 6 16 6 57...

Страница 210: ...no VIDEO si ml VS Q VERTICAL SYNC REQUEZT signal VSYNC VERTICAI SYNC A 4...

Страница 212: ...IV DC CONTROLLER DC controller 112 fi 6 4 3 I 2 I 1 A 6...

Страница 213: ...DC controller 2 2 iy j A 7...

Страница 215: ...Pick up motor driver 2 2 SENSOR PCB J602 0 A pA J602 bB1 pA J602 om pB I 24UA IPlO 1 SD A 9...

Страница 216: ...D I R 7...

Страница 217: ...VII PAPER FEEDER DRIVER 3 I 1 A 11...