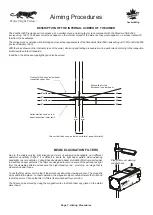

Position aimer at front of bay. Switch on laser by pushing button on laser housing. Measure center of laser beam height from floor at front

wheel and at back wheel. The distance from the floor should be the same. If it is not, adjust floor slope knob until they are equal. See fig.

16 and fig. 19. The laser has a built in timer and turns off automatically.

Calibrating the Floor

Floor compensation is required.

Vehicle and aimer are both located on a flat and level floor.

INITIAL FLOOR SLOPE COMPENSATION

Vehicle and aimer are both located on a flat floor with a

constant slope.

Floor compensation is required.

Vehicle and aimer are located on different flats, both of them

with a constant slope.

Floor compensation is required.

Vehicle and/or aimer are located on irregular flats.

It is recommended not to aim the headlamps on such

floors.

LASER GUIDED FLOOR SLOPE COMPENSATION SYSTEM

CAUTION

AVOID EXPOSURE - LASER LIGHT

IS EMITTED FROM THIS APERTURE

LASER RADIATION

DO NOT STARE

INTO BEAM

POWER OUTPUT < 1mW

WAVELENGHT: 630-680 nm

CLASS II LASER PRODUCT

fig. 16

RECORDING THE FLOOR SLOPE SETTING

Floor slope adjustment knob

9

8

7

6

5

4

3

2

1

…

†

fig. 19

Near the floor slope adjustment knob , there is a register consisting of a small cylinder that can be used to count the turns of the knob .

…

…

This register sinks or raises with each turn of the knob (fig. 19).

Shops using the aimer in more than one location should record the floor slope settings for each location.

ONCE THE SETTING IS RECORDED, IT IS NOT NECESSARY TO TAKE THE FLOOR SLOPE MEASUREMENT AGAIN FOR THIS

LOCATION.

Use the recorded floor slope setting for subsequent uses in the same location. Simply set the slope adjustment knob to the previously

recorded position prior to aiming headlights.

Bay No.

Register

Knob

Page 4 - Calibrating the Floor

Record floor slope information here for future reference.

Canbuilt Mfg.

Perfect Night Vision.....

Содержание OPT-5405

Страница 18: ......

Страница 20: ...NOTES...