Azur 752BD

Service Manual

3

Chapter One About Maintenance

1.1 Safety precautions

1.1.1 Power supply When maintenance personnel are repairing players ,he should pay special

attention to the power board with ~100V-240V and DC154V-300V which will cause hurt and damage to

persons!

1.1.2 When replacing accessories, please remove the power plug from socket to avoid any injures to

human body.

1.2 Precautions

1.2.1 Precautions for laser head

1

ǃ

Do not stare at laser head directly for laser emission will occur when laser head is working

which will hurt your eyes!

2

ǃ

Do not use wiping water or alcohol to clean laser head ,and you may use cotton swab.

1.2.2 About placement position

1

ǃ

Never place player in positions with high temperature and humidity.

2

ǃ

Avoid placing near high magnetic fields , such as loudspeaker or magnet .

3

ǃ

Positions for placement should best able and secure.

1.2.3 Electro static precautions

1

ǃ

Maintenance facility and working table must be earthed.

2

ǃ

Maintenance man must wear electrostatic ring, and he can use antistatic gloves instead when

electrostatic ring is unavailable or inconvenient to use.

3

ǃ

When repairing accessories, antistatic bag is required to pack the accessory.

1.2.4 Precautions for welding

1

ǃ

The soldering tin wire must satisfy the local environmental protection requirement.

2

ǃ

Welding temperature must not above 350

ć

1.3 Required device for maintenance

Digital oscillograph ( 100MHZ)

ǃ

TV set(1080p)

ˈ

receiver

˄

support HDMI

˅ǃ

SMD rework station

Multimeter

ǃ

Soldering iron

ǃ

Pointed-pinchers

ǃ

Cutting nippers

ǃ

Forceps

ǃ

Electric screw driver

Terminals connecting cord

ǃ

Test disc etc.

-1-

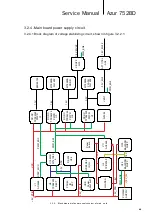

Note: After replacing load

e

r or main board,

please input BARCODE of the loader to main board again.

For input method, please refer to BARCODE input method on page 20.

-1-

-1-