ECB70

/

80

37

OM-ECB70

/

802019001-EN

OPERATOR MANUAL

36

OM-ECB70

/

802019001-EN

Braking Fluid Replacement

1.Run the forklift until the driving axle gets lightly heated. Park the forklift on a level floor, apply

the hand brake, switch off the forklift, remove the key and press down the emergency disconnect

switch.

2.Clean the surrounding area around the braking fluid drains plug, and place a container below it.

3.Remove the braking fluid drain plug and drain the braking fluid.

4.Reinstall the braking fluid drain plug and tighten it securely.

5.Add some braking fluid into the braking fluid reservoir. Slightly loosen the braking fluid drains

plug and press down brake pedal once completely to exhaust air out. Repeat this procedure more

than 3 three times until the air is removed completely and add braking fluid to 2/3 of the braking

reservoir.

6.Tighten braking fluid drain plug and clean the residual fluid spill.

Steering Axle Lubrication

Add grease to the steering axle through the lubrication nozzle in the steering axle.

Operate the grease applicator until fresh grease overflows.

Note

1.If the forklift is used in a place dusty, dirty, or having a lot of chemicals, lubricate the bearings

on a weekly basis to extend their service life.

2.The method of increasing grease application times but decreasing grease amount applied each

time is better than the method of decreasing grease application times but increasing great amount

applied each time.

Mast Maintenance

Chains Adjustment

The standard mast has the main lift chain that is needed to be adjusted, the free list mast has the

main lift chain set and the free lift chain that are needed to be adjusted. Before adjustment, park the

forklift on a level ground and fully lower the mast, switch off the forklift, take off the key and press

down the emergency disconnect button.

1.Standard mast lift chain adjustment

Loosen the upper and lower nuts of the lift chain, and then screw the middle nut to adjust the

length of the chain. After adjustment, make the forks remain level and the chains remain the same

tightness, and then tighten nuts.

Caution

After adjustment, make sure that the chains aren't slack when the lift cylinder is in the original

position.

2.Free lift mast lift chain adjustment

(1)Loosen the upper and lower nuts of the lift chain, and then screw the middle nut to adjust the

length of the chain. After adjustment, make the chains remain the same tightness, and them tighten

nuts.

(2)Loosen the upper and lower nuts of the free lift chain, and then screw the middle nut to adjust

the length of the chain. After adjustment, make the forks remain level and the chains remain the

same tightness, and them tighten nuts.

Chains Lubrication

1.Clean the exterior of the lift chain and remove dust and debris.

2.Add the machine oil and let it penetrate the chain joint.

3.After lubrication, lift and lower the mast several times.

Mast Cleaning

Take out debris between the roller and the channel of the mast.

Mast Clearance Adjustment

1.General Description of Mast Roller

A circlip locks the mast roller, bearing, and the dust protection that are installed on the mast

or the carriage stub. The bearing is used to adjust the clearance of the mast and carriage by the

adjusting screw, which is installed on the other side of the stub. Adjusting screw is secured by a

secure pin.

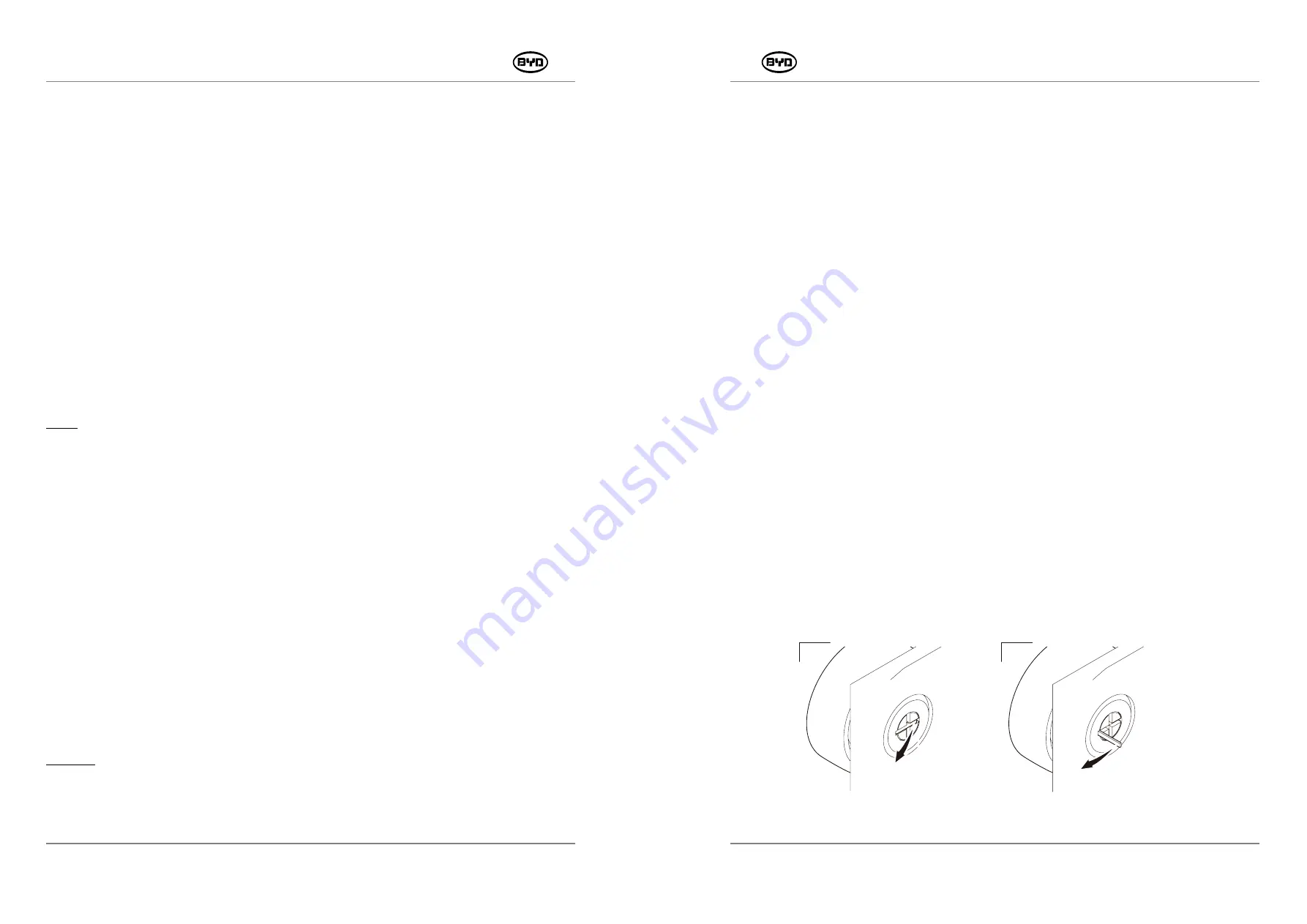

2.General Carriage and Mast Clearance Adjustment Procedure

(1)Lift the mast to expose the position of the adjusting screw.

(2)Bend the secure pin to expose the adjusting screw.

(3)Use the screw to adjust the clearance.

(4)After adjustment, bend the secure pin to secure the adjustment screw.

< 1

<

>

2 >

Содержание ECB70

Страница 1: ...ECB70 ECB80 OPERATOR MANUAL OM ECB70 802019001 EN...

Страница 23: ......