Page 41 of 106

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

KENDO.30LIGHT-KENDO.30LIGHTFI

7105-M002-0_B

The arm advance cam is not imme-

diately activated.

1. Supply missed.

2. The control push button is

broken.

1. Connect the supply.

2. Call for technical assistance.

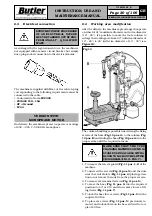

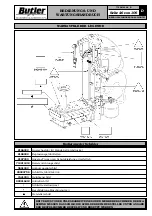

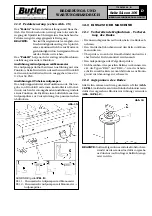

15.0 TECHNICAL DATA

Recommended air supply pressure .............

8 - 10 bar

Motor speed ..................................................

15 rpm

Raccomanded

electric supply.........................

monophase 0,75 kW -

200

÷

265V - 50/60 Hz

Maximum wheel diameter ......................

41”/43”/45”

Wheel max. width ................................................

15”

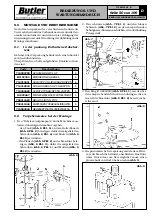

Rim locking diameter ...........

10”-26”÷12”-28”÷14”-30”

Bead-breaker power per roller (10bar) ...........

1200 kg

Vertical bead breaker max. opening ...............

900 mm

Gear noise .....................................................

dBA 76

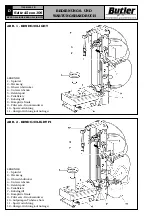

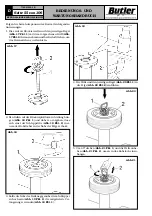

15.1 Weight

Model without tubeless inflation .....................

330 kg

Model with tubeless inflation ..........................

338 kg

Problem

Possible cause

Rimedy

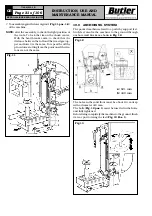

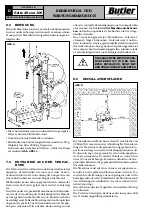

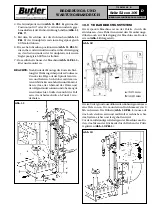

14.0 FAULT - FINDING

The chuck doesn’t rotate.

The chuck doesn’t reach maximum

speed.

1. The first limit current is over.

2. The second limit current is over.

3. Supply missed.

4. Mains voltage insufficient.

5. Mains voltage too high.

6. Loss and prompt mains voltage.

7. The second temperature limit is

over.

1. The first temperature limit is

over.

2. Mechanical resistence is in-

creased.

1. Wait the automatic restoration

lifting the pedal.

2. Disconnect the machine from net

for 30 seconds at least and then

connect it again.

3. Connect the supply.

4. Shorten the lenght of the machine

extension cable or increase the

conductors section (disconnect

and hang up).

5. Disconnect the machine from net

for 30 seconds at least and then

connect it again.

6. Disconnect the machine from net

for 30 seconds at least and then

connect it again.

7. The machine DOESN’T restart

even the temperature is not un-

der the safety limit.

1. Wait for motor/inverter unit cool-

ing.

2. Turn (without wheel) the chuck

unit for few minutes. If at the end

the chuck doesn’t accelerate call

for technical assistance.

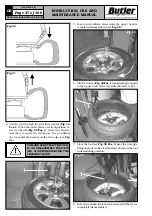

The inflation pedals are badly ad-

justed.

Call for technical assistance.

The nozzle doesn’t supply air when

the inflation pedal is pressed (Only

for FI version).