INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 33 of 43

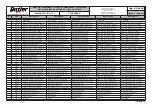

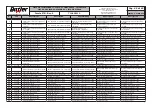

14.0 TROUBLESHOOTING TABLE

Possible troubles which might occur to the tyre-changer are listed below. The manufacturer disclaims all

responsibility for damages to people, animals or objects due to improper operation by non-unauthorised

personnel. In case of trouble, call Technical Service Department for instructions on how to service and/or

adjust the machine in full safety to avoid any risk of damage to people, animals or objects.

In an emergency and before maintenance on tyre-changer, set the main switch to “0” and lock it in this position.

CONTACT AUTHORIZED TECHNICAL SERVICE

do not try and service alone

Problem

Possible cause

Remedy

The bead breaking arms do not

hold their position once they are

adjusted on a diameter.

1. Compressed air supply pressure

below 6 Bar.

2. The positioning cylinder is badly

adjusted.

1. Check supply pres-

sure.

2. Call for technical as-

sistance.

The arm advance cam (in auto-

matic position) is immediately

activated.

1. The feeler pin is unscrewed.

2. The connectors are extracted.

3. The feeler pin position is badly

adjusted.

1. Screw the feeler pin well.

2. Check the connectors in the rear

part of the arm

3. Set the feeler pin position

The nozzle doesn’t supply air when

the inflation pedal is pressed (only

for versions with tubeless infla-

tion).

The inflation pedal is badly ad-

justed.

Call for technical as-

sistance.

The mandrel doesn’t rotate.

Inverter overload alarm

Or

Inverter undervoltage alarm

Or

Inverter overvoltage alarm

Shorten the length of a possible

machine extension cable or in-

crease the conductors section

(disconnect and connect again).

Lift the motor pedal and wait for

the automatic reset.

Overtemperature alarm.

Wait until the motor system cools

(the machine does not restart if

the temperature level does not go

below the set safety threshold).

The mandrel does not reach the

maximum rotation speed.

The mechanical resistance of the

gearmotor system has increased.

Turn the mandrel with-

out wheel for a few min-

utes so that the system

heats, thus reducing

frictions.

If in the end the man-

drel does not accelerate

again, call for technical

assistance.

The mandrel does not rotate in

counter-clockwise direction.

Pedalboard microswitch breakage. Replace microswitch.

The mandrel doesn’t rotate, but

it attempts rotation when the ma-

chine is switched on again.

Pedalboard irreversible de-cali-

bration.

Call for technical as-

sistance.

7104-M009-2_B

AIKIDO.4 - AIKIDO.4FI