INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 18 of 43

12.0 USING THE MACHINE

12.1 Precaution measures during tyre re-

moval and fitting

Before fitting a tyre, observe the following safety rules:

• rim and tyre must be clean, dry and in good condi-

tion; if necessary, remove the balancing weights and

clean the rim. Check that:

- neither the bead nor the tread of the tyre are dam-

aged;

- the rim does not produce dents and/or deformation

(especially for alloy rims, dents can cause internal

micro-fractures, that pass unobserved at visual

inspection, and can compromise the solidity of the

rim and constitute danger even during inflation);

• adequately lubricate the contact surface of rim and

tyre bead, using specific tyre lubricants only;

• replace the inner tube valve with a new valve, if the

tyre tube has a metal valve, replace the grommet;

• make sure that the tyre is the right size for the rim;

on the contrary, never fit a tyre unless you are sure it

is of the right size (the rated size of the rim and tyre

is usually printed directly on each of them);

• do not use compressed air or water jets to clean the

wheels on the machine.

12.2 Preliminary operations - Preparing the

wheel

• Remove the wheel balancing weights from both sides

of the wheel.

• Remove the valve stem and allow the tyre to com-

pletely deflate.

• Establish from which side the tyre should be de-

mounted, checking the position of the groove.

• Find the rim locking type.

• Try to establish the special types of wheels, such as

“EH2” and “EH2+”, in order to improve locking, bead

breaking, assembly and disassembly performances.

W H E N H A N D L I N G W H E E L S

WEIGHING MORE THAN 10 KG

AND/OR WITH A FREQUENCY

OF MORE THAN 20/30 WHEELS

PER HOUR, A LIFTING DEVICE

SHOULD BE USED.

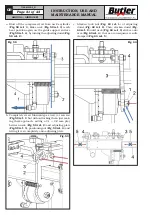

12.3 Wheel clamping

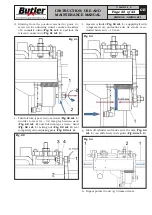

All wheels must be locked on the rubber plate (

Fig. 17

ref. 1

) through the central hole using the proper locking

ring nut (

Fig. 17 ref. 2

).

Fig. 17

IN CASE OF USE OF RIMS WITH-

OUT CENTRAL HOLE, IT’S NECES-

SARY TO USE THE PROPER FIX-

TURE (AVAILABLE ON DEMAND).

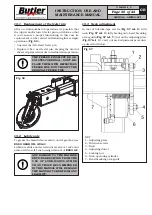

To lock a rim proceed as follows:

1. Dowel the wheel (

Fig. 18 ref. 1

) on the rubber plate

and check that the dragging pin (

Fig. 18 ref. 2

)

enter in a hole placed on the rim hub.

Fig. 18

IF THE WHEEL HUB IS HIGH-

ER THEN THE DRAGGING PIN

(FIG. 19 REF. 2), USE THE EXTEN-

SION (FIG. 19 REF. 1) SUPPLIED

ON ISSUE.

7104-M009-2_B

AIKIDO.4 - AIKIDO.4FI