INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 29 of 43

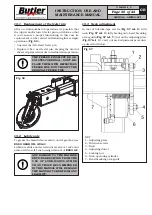

IN ORDER TO ENSURE A GOOD

FUNCTIONING AND TO AVOID THE

PRESENCE OF CONDENSATION

IN THE AIR TREATMENT UNITS

WITH SEMI-AUTOMATIC DRAIN,

IT'S NECESSARY TO MAKE SURE

ABOUT THE CORRECT POSITION

OF THE VALVE (FIG. 54 REF. 1),

PLACED UNDER THE CAP. TO

ACTIVATE A CORRECT DRAIN

FUNCTION, THE CAP MUST BE

ROTATED IN THE RIGHT WAY.

IN ORDER TO ALLOW A LONGER

LIFE OF THE FILTER AND OF ALL

MOVING PNEUMATIC DEVICES,

YOU HAVE TO MAKE SURE THAT

THE SUPPLIED AIR IS:

• EXEMPT FROM THE LUBRICAT-

ING OIL OF THE COMPRESSOR;

• EXEMPT FROM HUMIDITY;

• EXEMPT FROM IMPURITY.

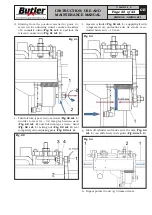

• Periodically, with a frequency of at least once a month,

lubricate the arms of the bead breaking roller and

of the tools.

• Immediately replace worn parts, bead breaking rolls,

assembly tools, feeler pins.

• At regular intervals, at least every two months, verify

the rubber guard conditions, in relation to point 3.0

Safety devices. If necessary replace damaged parts

requesting for them to the supplier.

• Every

week

and/or when necessary, top up the oil

tank using the filler hole provided, closed by a cap

or screw, on the lubricator filter.

NOTE: This operation should not be carried out by

unscrewing the cup of the lubricator filter.

• The use of synthetic oil might damage the pressure

regulator filter.

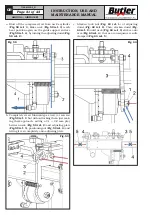

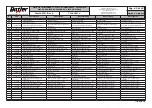

• Periodically (at least every 100 working hours) check

reduction gear lubricating oil level (

Fig.

55 ref. 5

).

Such operation must be effectuated unscrewing the

screws (

Fig.

55 ref. 1

), removing the flange (

Fig.

55

ref. 2

), the guard (

Fig.

55 ref. 3

) and the plug (

Fig.

55 ref. 4

) on the reduction gear.

Fig. 55

ANY DAMAGE TO THE MACHINE

DEVICES RESULTING FROM THE

USE OF LUBRICANTS OTHER

THAN THOSE RECOMMENDED

IN THIS MANUAL WILL RELEASE

THE MANUFACTURER FROM ANY

LIABILITY!!

7104-M009-2_B

AIKIDO.4 - AIKIDO.4FI