burster Italia s.r.l. · Sede legale ed operativa · Via Cesare Battisti, 16/18 · 24035 Curno (BG) · Tel. +39 035 618120 · Fax +39 035 618250

e-mail: [email protected] · http://www.burster.it

C.F. e P.IVA 11048400151 · Capitale sociale Euro 49.920,00 · R.E.A. di Bergamo 276749

Apparecchi di misura di precisione. Sensori e Sistemi

per grandezze elettriche, termiche e meccaniche

6.5

Speed Limits

The maximum speed indicated in the data sheet may not be exceeded in any operating state.

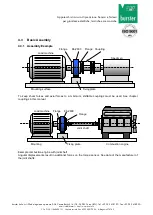

6.5.1 Balancing

The sensor is balanced (for balancing quality see datasheet). At high speeds, it is recommended to

perform one operational balancing.

Balancing bores may not be applied out on the sensor!

6.6

Disturbance Variables

Measured value falsifications can occur by

Vibrations,

Temperature gradients,

Temperature changes,

Emerging disturbance variables during operation, e.g. imbalance,

Electrical disturbances,

Magnetic disturbances,

EMC (electromagnetic disturbances),

Therefore avoid these disturbance variables by decoupling of vibrations, covers, etc.

7

Maintenance

Maintenance schedule

Action

Frequency

Date

Date

Date

Control of cables and connectors

1x p.a.

Calibration

< 26 months

Control of fixation (flanges, shafts)

1x p.a.

7.1

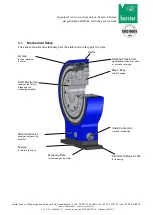

Rotating Sensors

This sensor type is largely maintenance free.

7.2

Trouble Shooting

This table is used to find the most common errors and debugging.

Problem

Possible Cause

Debugging

No signal

No sensor excitation

Outside of permissible range

Connect excitation

Cable defect

No mains supply

Signal output connected wrong

Connect output correctly

Evaluation electronics defect

Sensor does not react to torque

Shaft not clamped

Clamp correctly

No power supply

Outside of permissible range

Connect supply

Cable defect

No mains supply

Cable defect

Repair cable

Connector connected wrong

Connect correctly

Signal has dropouts

Axial position rotor to stator

outside of tolerance

Align rotor

Cable defect

Repair cable